17ir33 platform “connections” +030220445 - rel. 2.3 - 27.04.2011

ENGLISH

Connections

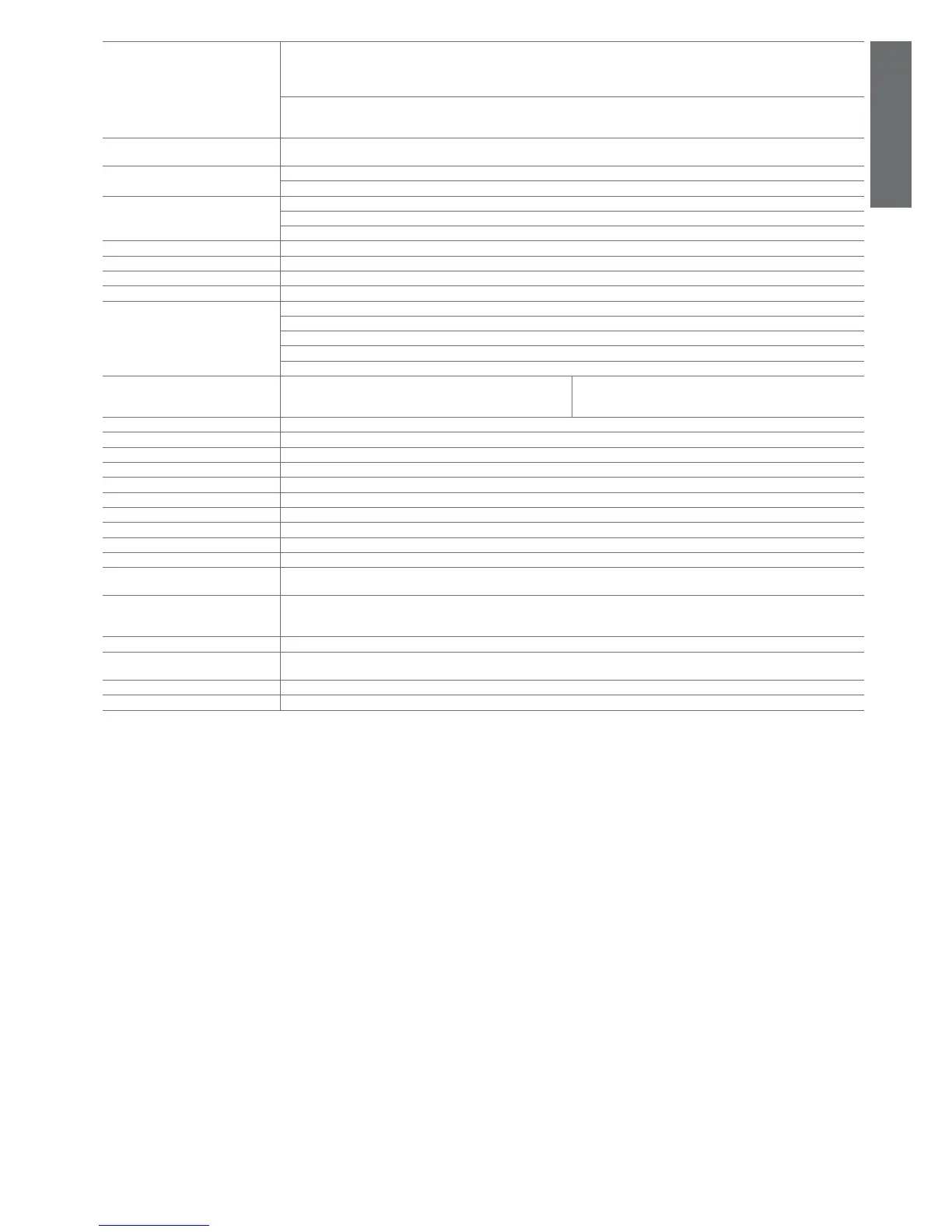

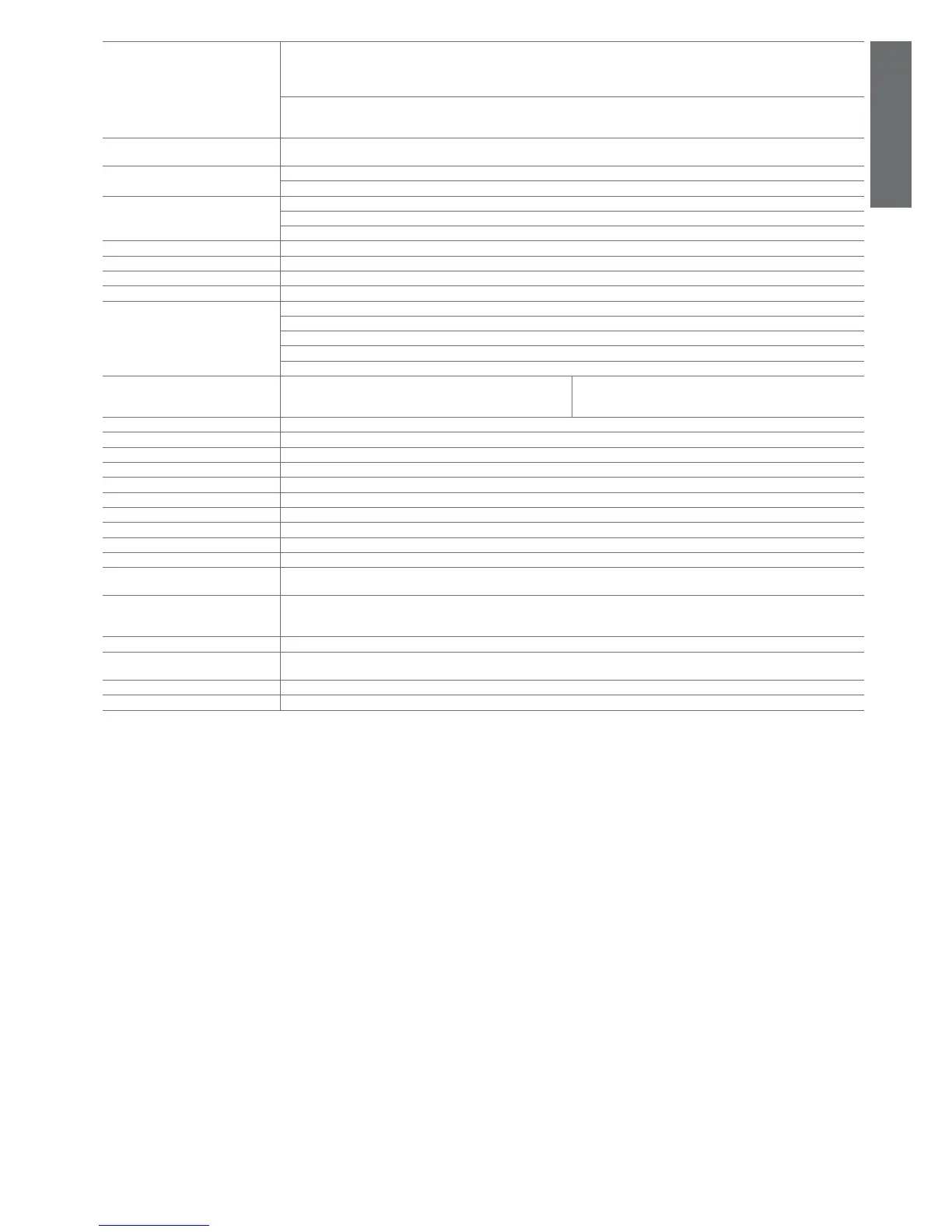

Type of connection Cross-sections Max current.

fi xed screw 16A for cables from 0.5 to 4.2 mm

2

16A

fi xed screw for cables from 0.5 to 2.5 mm

2

12A

estraibili per blocchetti a vite

The correct sizing of the power and connection cables between the instrument and the loads is the responsibility of the installer.

Depending on the model, the maximum current at the common terminals is 12A or 16A. In the max load and max operating temp. conditions,

the cables used must be suitable for operation up to 105°C.

Case plastic: E, A dimensions 34.4x76.2x65 mm - mounting depth 56.5 mm

O, L, H dimensions 34,4x76,2x79 mm - mounting depth 70,5 mm

Assembly smooth, hard and indeformable panel: side fastening brackets, to be pressed in fully

drilling template: dimensions 28.8 ± 0.2 x 70.8 ± 0.2 mm

Display digits: 3 digit LED

display: from -99 to 999

operating status: indicated with graphic icons on the display

Keypad 4 silicone rubber buttons

Infrared receiver available depending on the model

Clock with backup battery available depending on the model

Buzzer available in all models

Clock error at 25 °C: ± 10 ppm (±5.3 min/year)

error in the temperature range -10T60 °C: - 50 ppm (-27min/year)

ageing: < ± 5 ppm (±2.7 min/year)

discharge time: typically 6 months (8 months maximum)

recharge time: typically 5 hours (< 8 hours maximum)

Operating temperature IRxxxx(E,A)(P,Q,S,U,V,X,Y,Z)xxx

IRxxxx(E,A,0,L,H)(N,R,C,B,A,M,L,T)xxx

IRxxxx(0,L)(H,I,E,F,G,K,O,W))xxx

-10T60 °C

Operating humidity <90% RH non-condensing

Storage temperature -20T70 °C

Front panel index of protection assembly on smooth and indeformable panel with IP65 gasket

Environmental pollution 2, normal situation

PTI of insulating materials printed circuits 250, plastic and insulating materials 175

Period of stress across the insulating parts long

Category of resistance to fi re category D and category B (UL 94-V0)

Class of protection against voltage surges category II

Type of action and disconnection 1B relay contacts (micro-disconnection)

Construction of the control device electronic control device incorporated

Classifi cation according to protection

against electric shock

class II when appropriately integrated

Device designed to he hand-held or

integrated into equipment designed to

be hand-held

no

Software class and structure class A

Cleaning the front panel of the instru-

ment

only use neutral detergents and water

Serial interface for CAREL network External, available in all models

Programming key Available in all models

Table 4.a

Loading...

Loading...