33

t

T

STEP1

P71=45’

P72=Set

STEP2

P73=45’

P74=Set

Set

45’45’

t

T

STEP1

P71=30’

P72=Set1

STEP2

P73=60’

P74=Set1

STEP3

P75=30’

P76=Set2

60’

Set1

Set2

30’ 30’

t

T

STEP1

P71=60’

P72=Set2

STEP2

P73=30’

P74=Set1

STEP3

P75=30’

P76=Set1

Set1

Set2

t

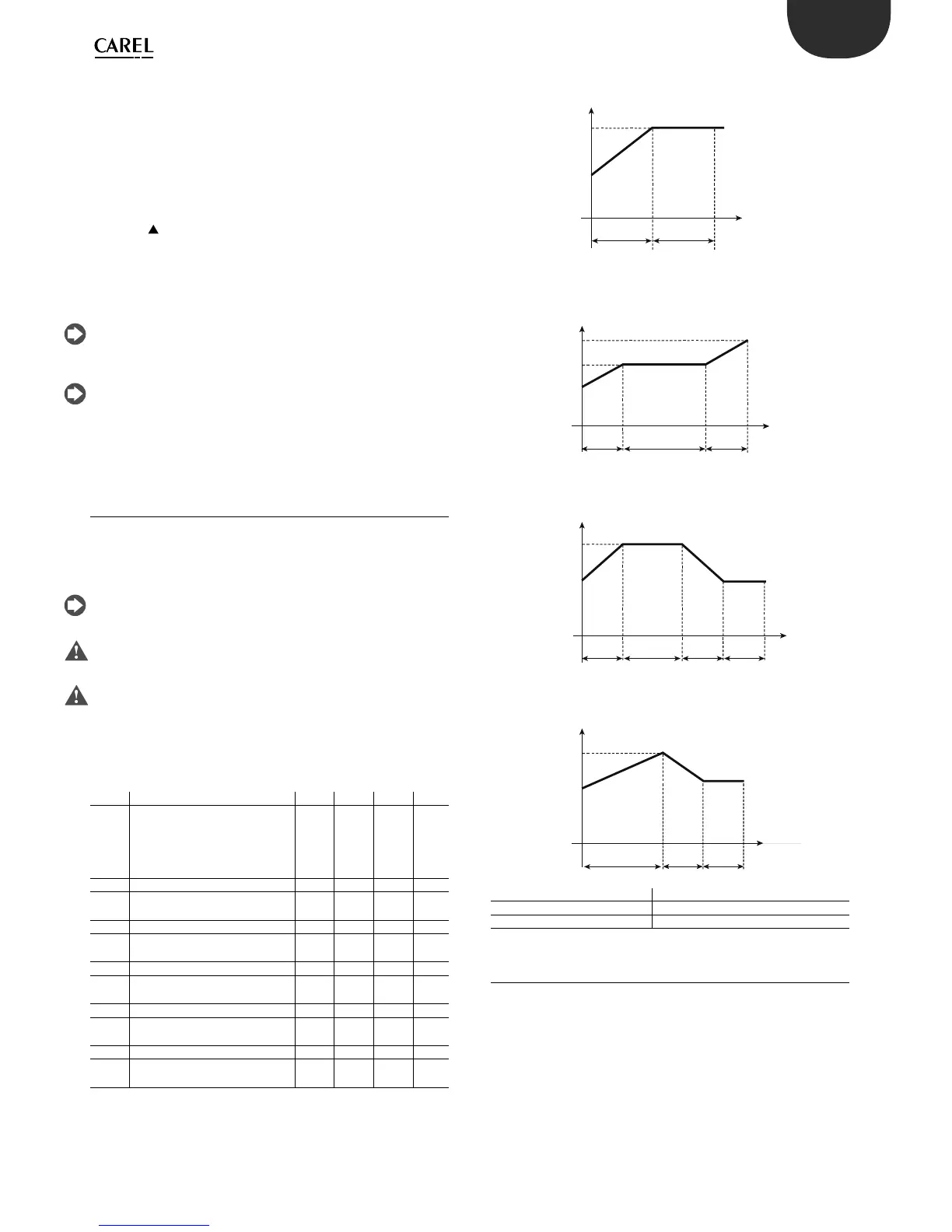

T

STEP1

P71=30’

P72=Set2

STEP2

P73=45’

P74=Set2

STEP3

P75=30’

P76=Set1

STEP4

P77=30’

P78=Set1

45’

Set1

Set2

60’

30’ 30’

30’ 30’

30’

ENG

ir33 universale +030220801 - rel. 1.0 - 16.04.2008

procedure can be repeated to further tune the values. This is useful when

the loads have changed since the rst procedure was performed, or to

allow ner tuning. The controller in this case can manage the system

using the PID parameters, and further Auto-Tuning will have the e ect

of improving control.

This time, the procedure can be started during normal control of the

system (with c0 =1 or 2, that is, control in “direct” or “reverse” mode, and c5

=1, that is, PID control enabled); the controller in this case does not need

to be switched o and on again; simply:

-set parameter c64 to 1;

-press the

button for 5 seconds, after which the unit will display the

message “tun” and Auto-Tuning will start.

The controller then proceeds with Auto-Tuning as already described

above. In both modes described, if the procedure ends positively, the

controller will automatically set parameter c64 to zero and will activate

PID control with the new parameters saved.

The Auto-Tuning procedure should not be considered essential in

achieving optimum control of the system; experienced users can also

achieve excellent results by setting the parameters manually.

For users experienced in operating the IR32 Universal family controllers

in P+I mode, simply set c5=1 (that is, PID control enabled) and use the

default values of the parameters, thus replicating the behaviour of the

previous model of controller.

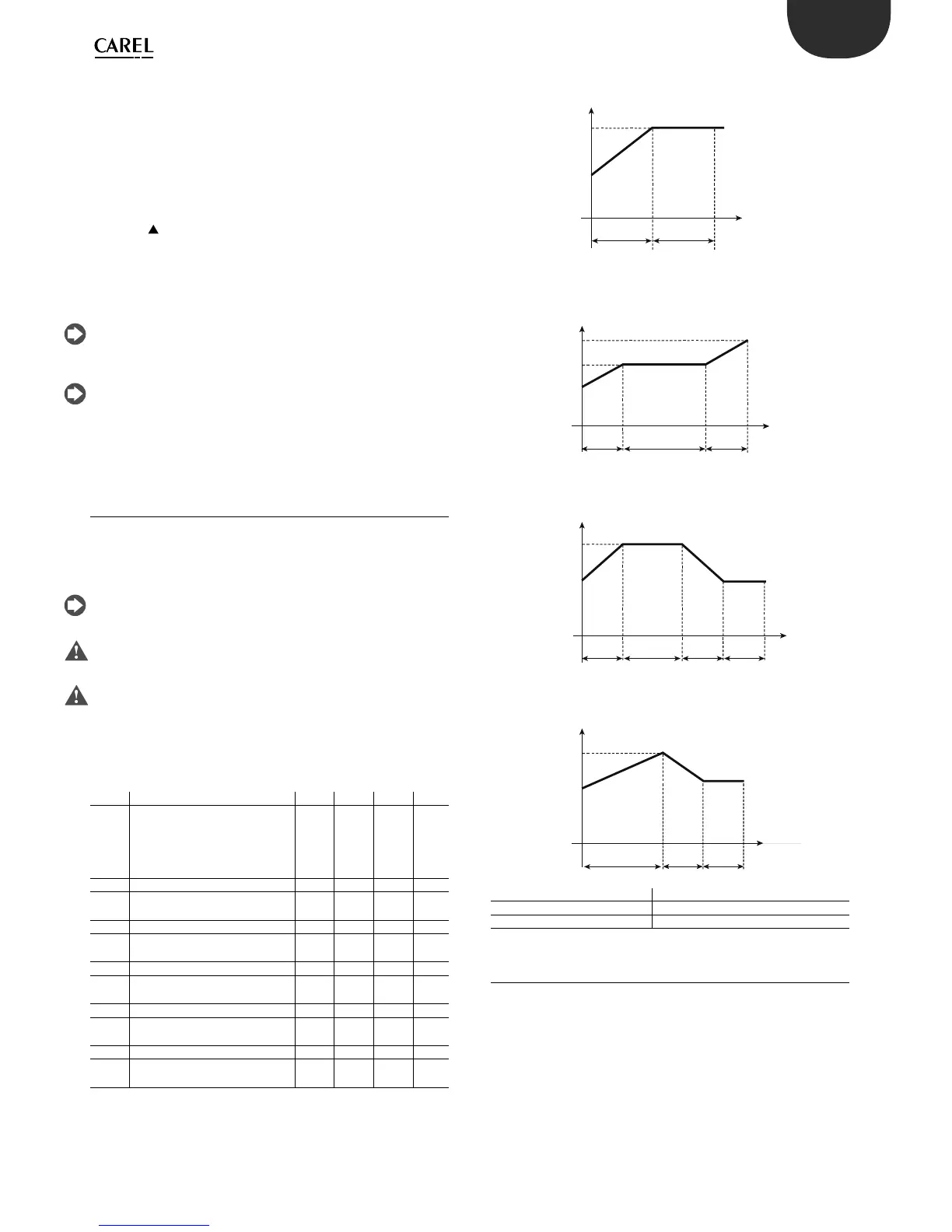

6.4 Operating cycle

The operating cycle is an automatic program that can have a maximum

of 5 set points to be reached in the 5 respective time intervals. This may

be useful for automating processes in which the temperature must follow

a set pro le for a certain time (e.g. milk pasteurisation).

The operating cycle is started from the keypad, digital input or

automatically by RTC. See the chapter on the “User interface”.

The opening of the digital inputs does not a ect the

operating cycle, which continues as de ned by the program.

If the duration of step x, (P73, P75, P77, P79) is set a zero, it means that

the controller only manages the temperature. The controller will try to

reach the set temperature in the shortest possible time, after which it will

go to the next step. On the contrary, P71 must be set ≠ 0. With duration

of the step ≠ 0, the controller will try to reach the set temperature in the

established time, and then anyway it will go on to the next step.

Par. Description Def Min Max UoM

P70 Enable operating cycle

0=Disabled

1=Keypad

2=Digital input

3=RTC

003 -

P71 Oper. cycle: duration of step 1 0 0 200 min

P72 Operating cycle: temperature

set point step 1

0 -50 150 °C/°F

P73 Oper. cycle: duration of step 2 0 0 200 min

P74 Operating cycle: temperature

set point step 2

0 -50 150 °C/°F

P75 Oper. cycle: duration of step 3 0 0 200 min

P76 Operating cycle: temperature

set point step 3

0 -50 150 °C/°F

P77 Oper. cycle: duration of step 4 0 0 200 min

P78 Operating cycle: temperature

set point step 4

0 -50 150 °C/°F

P79 Oper. cycle: duration of step 5 0 0 200 min

P80 Operating cycle: temperature

set point step 5

0 -50 150 °C/°F

Example 1: Heating cycle with in nite temperature control

Example 2: Heating cycle with intermediate pauses and stop at the end

Example 3: Low pasteurisation cycle

Example 4: High pasteurisation cycle

Key

T Temperature

t Time

6.5 Operation with probe 2

Installing probe 2 allows various types of operation to be enabled,

selected using parameter c19

6.5.1 Di erential operation (parameter c19=1)

The second probe (B2) must be installed. Control is performed by

comparing the set point St1 against the di erence between the two

probes (B1-B2). In practice, the controller acts so that the di erence B1-B2

is equal to St1. As mentioned, the management of the second probe is

only available in modes c0=1 & 2.

“Direct” operation (c0=1) is suitable for applications in which the controller

needs to stop the di erence B1-B2 from increasing.

“Reverse” operation (c0=2), on the other hand, stops the di erence B1-B2

from decreasing. Below are some examples of applications.

Loading...

Loading...