34

B1 (T1) B2 (T2)

CHILLER

St1=5

OUT2 OUT1

Mod. W

B1-B2

P1

ON

OFF

B2 (T1) B1 (T2)

CHILLER

St1=-5

OUT1 OUT2

Mod. W

B1-B2

P1

ON

OFF

L Ncompressor 1

OUT2 OUT3

OUT4

OUT1

compressor 2

alarm

P25=6 St2=8

OUT1 (LOW ALARM) OUT2

Mod. Z

B1 (T2)

P2P27

ON

OFF

St1=-5

OUT3 OUT4

Mod. W

B1-B2

P1

ON

OFF

ENG

ir33 universale +030220801 - rel. 1.0 - 16.04.2008

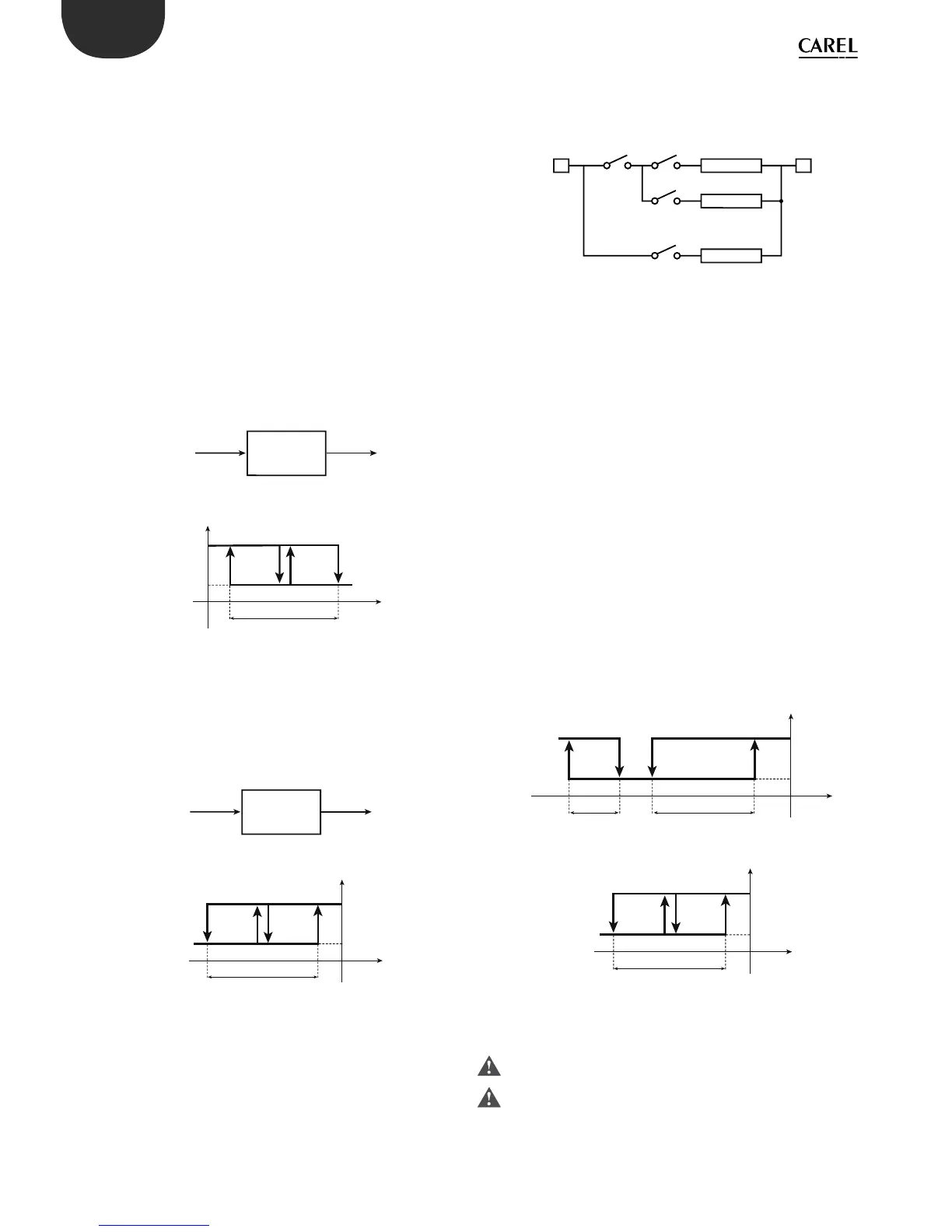

Example 1:

A refrigeration unit with 2 compressors must lower the temperature of

the water by 5°C.

Introduction: having selected a controller with 2 outputs to manage the

2 compressors, the rst problem to be faced relates to the positioning

of probes B1 and B2. Remember that any temperature alarms can only

refer to the value read by probe B1. The example indicates the inlet

temperature as T1 and the outlet temperature as T2.

Solution 1a: install B1 on the water inlet if it is more important to control

the inlet temperature T1; that will allow alarm signals, where necessary

delayed, relating to a “High” inlet temperature T1. For example, when

B1=T1 the set point corresponds to “B1-B2”, i.e. “T1-T2”, and must be equal

to +5°C (St1=5). The operating mode will be “reverse” (c0=2), given that

the controller activates the outputs as the value of “T1-T2” decreases,

and tends towards 0. Choosing a di erential equal to 2°C (P1=2), a high

temperature threshold equal to 40°C (P26=40) and a delay of 30 minutes

(P28=30), the operation will be as described in the following gure.

Solution 1b: if on the other hand priority is attributed to T2 (e.g. “Low

temperature” threshold 6°C with a one minute delay), the main probe,

B1, must be set as the outlet temperature. With these new conditions,

the set point St1, equal to “B1-B2”, i.e. ‘T2-T1’, must now be set to -5°C.

The operating mode will be “direct” (c0=1), given that the controller must

activate the outputs as the value of ‘T2-T1’ increases, and from -5 tends

towards 0. P25=6 and P28=1(min) activate the “Low temperature” alarm,

as shown in the new control logic diagram:

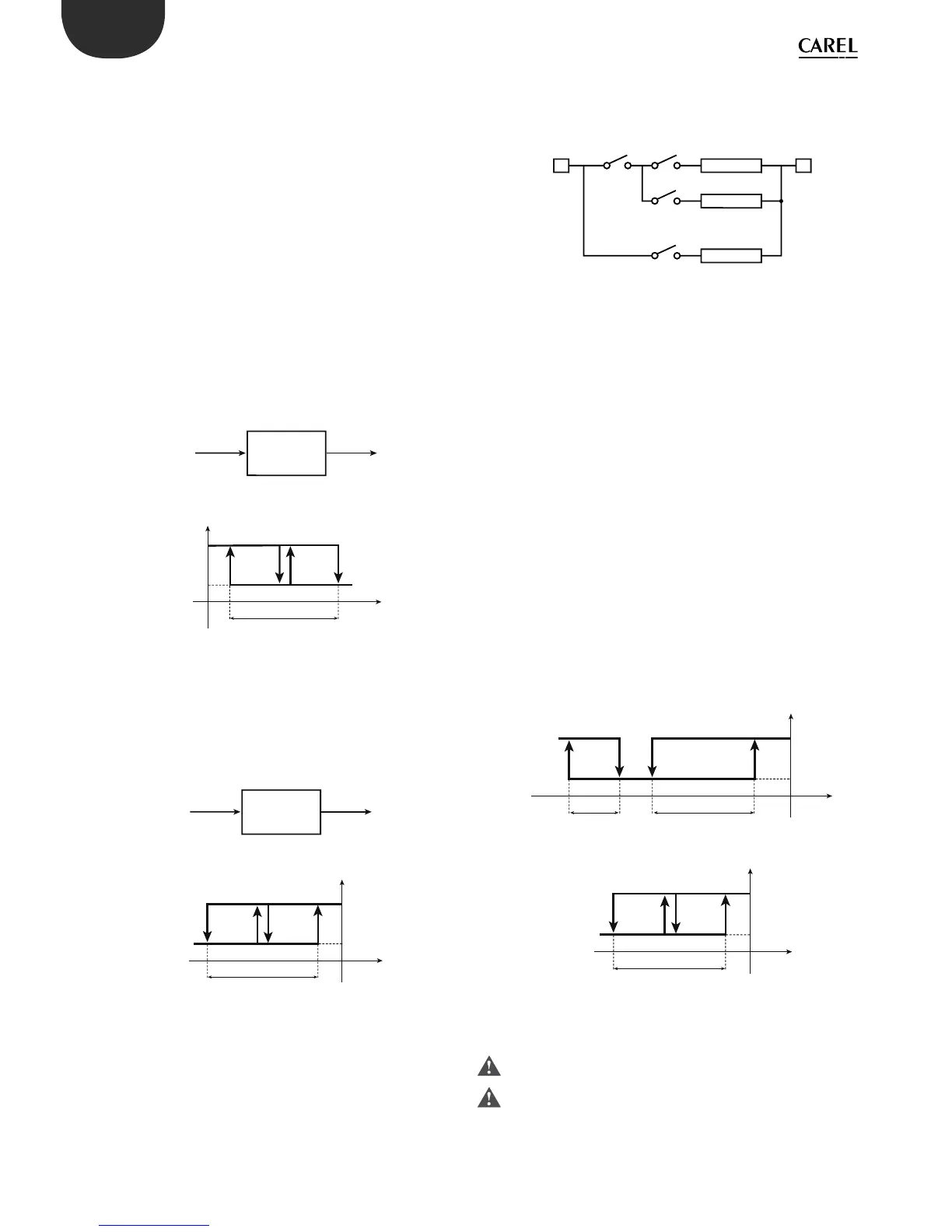

Example 1 (continued)

Example 1 can be resolved using “special” operation (c33=1). Starting

from solution 1b (T2 must be 5°C less than T1). The main probe is located

at the outlet (T2 =B1).

These requirements also need to be satis ed:

• the outlet temperature T2 must remain above 8°C;

• if T2 remains below 6°C for more than one minute, a “Low temperature”

alarm must be signalled.

Solution: use a controller with 4 outputs (IR33Z****); two outputs are

used for control (OUT3 and OUT4), and one for the remote alarm signal

(OUT1). OUT2 will be used to deactivate outputs OUT3 and OUT4 when

T2< 8°C. To do this, simply connect OUT2 in series with OUT3 and OUT4,

then make OUT2 active only when B1 (T2) is greater than 8°C.

Set c33=1: the changes to be made to the special parameters are:

Output 1: must be programmed as an alarm output that is active only

for the “Low temperature” alarm. Set “dependence”=c34, which changes

from 1 to 9 (or 10 to use normally ON relays). The other parameters for

output 1 are not relevant and remain unchanged.

Output 2: this becomes detached from di erential operation, changing

the “dependence” from 1 to 2: “dependence”=c38=2. The logic is “direct”

and includes all of P2, therefore “activation” =c40 becomes 100, and

“di erential/logic”=c41 becomes -100. St2 will obviously be set to 8 and

P2 represents the minimum variation required to restart control, once it

has stopped due to “Low temperature”, e.g. P2=4.

Output 3 and Output 4: in the controllers with 4 outputs, mode 1 assigns

each output an hysteresis of 25% of the di erential P1. In the example,

considering that 2 outputs are used for control, the hysteresis for

each output must be 50% of P1. The “activation” and “di erential/logic”

parameters for the outputs must be changed to suit the new situation.

In practice, this means setting:

Output 3:

“activation”=c44 changes from 75 to 50

“di erential/logic”=c45, changes from -25 to -50.

Output 4:

“activation”=c48 remains at 100

“di erential/logic” = c49 changes from -25 to -50.

The diagram summarises the controller operating logic.

6.5.2 Compensation

The compensation function is used to modify the control set point St1

according to the reading of the second probe B2 and the reference set point

St2. Compensation has a weight equal to c4, called the “authority”.

The compensation function can only be activated when c0=1,2.

When compensation is in progress, parameter St1 remains at the set

value; on the other hand, the operating value of St1 changes, known

as the e ective St1, that is, the value used by the control algorithm. The

e ective St1 is also restricted by the limits c21 and c22 (minimum and

maximum value of St1); these two parameters guarantee that St1 does

not reach undesired values.

Loading...

Loading...