36

St1_comp

c4>0

c22

c21

B2

P2P2

St1_comp

c4<0

c22

c21

B2

P2P2

St1

OUT2 OUT1

OUT

B1

P1

100%

0%

St1

C19=5

OUT2OUT1

OUT

B1

P1

100%

0%

c67-1,5 c67

ABILITAZIONE/

ENABLE

B2

ON

OFF

C19=6

c67-1,5

c67

ABILITAZIONE/

ENABLE

B2-B1

ON

OFF

C19=5

c66 c66+1,5

ABILITAZIONE/

ENABLE

B2

ON

OFF

C19=6

c66 c66+1,5

ABILITAZIONE/

ENABLE

B2-B1

ON

OFF

ENG

ir33 universale +030220801 - rel. 1.0 - 16.04.2008

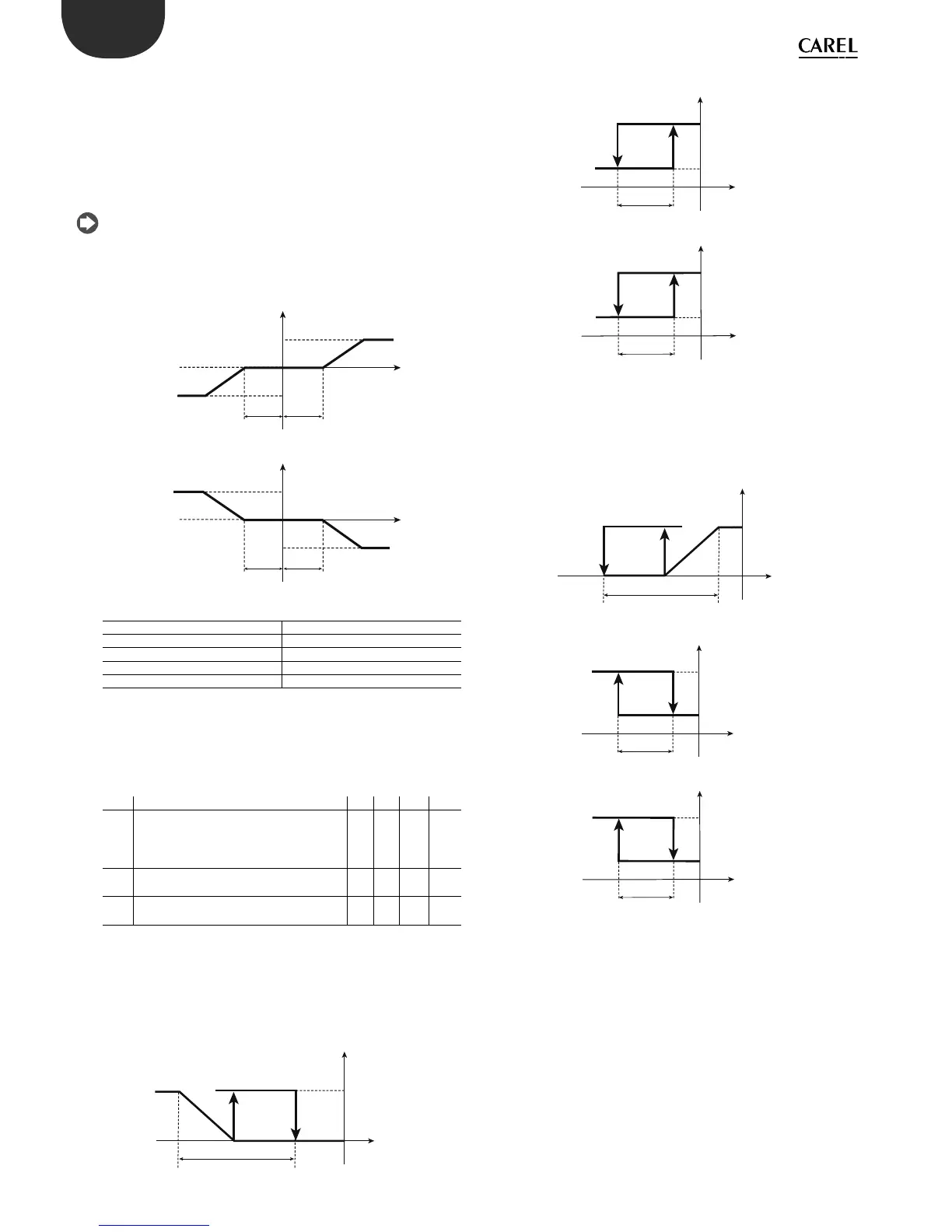

6.5.5 Continuous compensation (parameter c19=4)

The compensation of St1 is active for values of B2 other than St2: with

this value of c19, parameter P2 can be used to de ne a dead zone around

St2 in which compensation is not active, that is, when the value read by

B2 is between St2-P2 and St2+P2, compensation is disabled and St1 is

not changed:

if B2 is greater than (St2+P2), e ective St1 = St1+ [B2-(St2+P2)]*c4

if B2 is between (St2-P2) and (St2+P2), e ective St1 =St1

if B2 is less than (St2-P2), e ective St1 = St1+ [B2-(St2-P2)]*c4

Compensation using c19=4 is the combined action of compensation in

cooling and compensation in heating, as described above. The following

diagrams show continuous compensation for positive and negative

values of c4. Neglecting the e ect of P2, if c4 is positive St1 increases

when B2>St2 and decreases when B2<St2. Vice-versa, if c4 is negative St1

decreases when B2 > St2 and increases when B2 is below St2.

Key:

St1_comp E ective set point 1

B2 Outside probe

c4 Authority

c22 Maximum value of set point 1

c21 Minimum value of set point 1

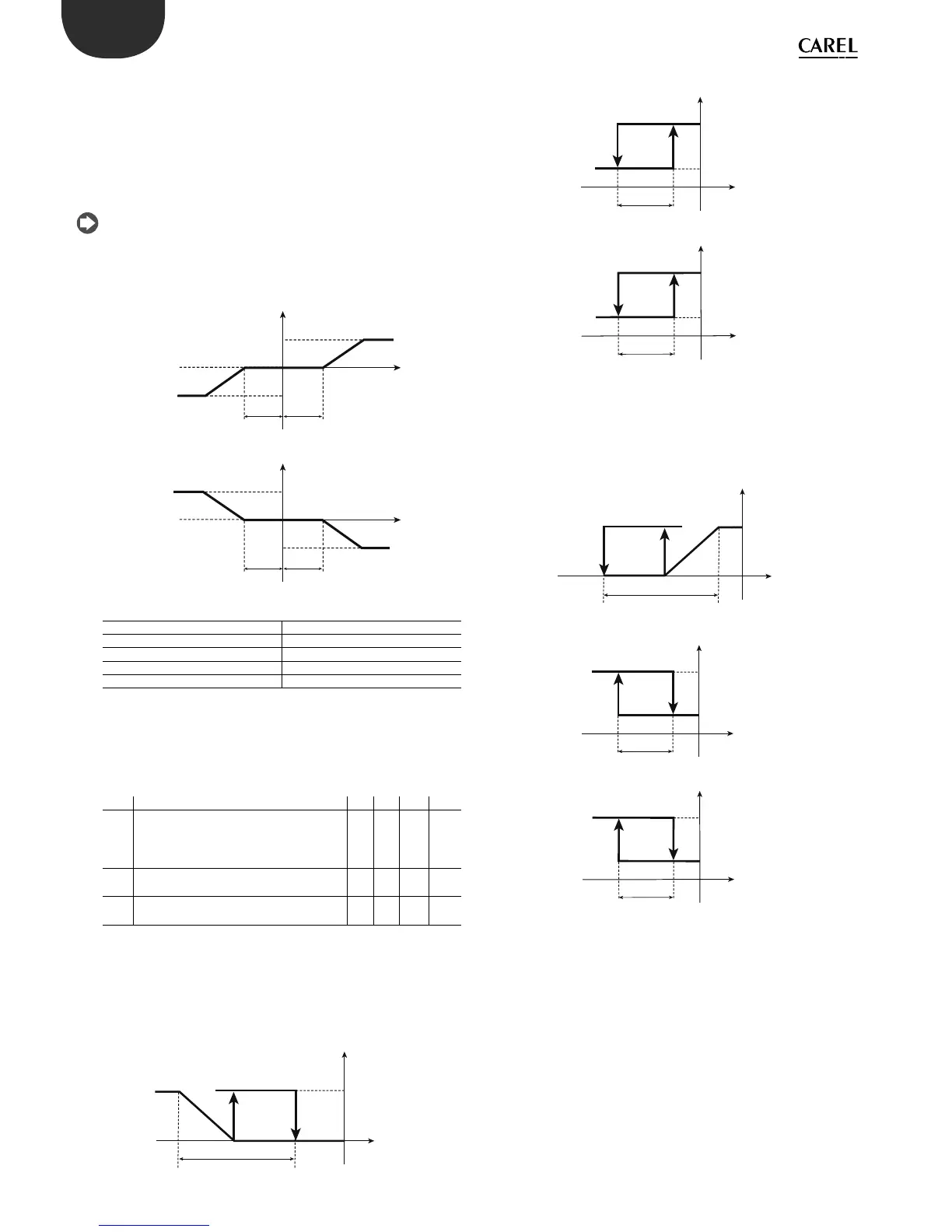

6.5.6 Enable logic on absolute set point & di erential

set point (parameter c19=5,6)

When c19=5 the value read by probe B2 is used to enable control logic in

both direct and reverse mode.

If c19=6 the value considered is B2-B1.

Par. Description Def Min Max UoM

c19 Operation of probe 2

5=enable logic on absolute set point

6=enable logic on di erential set point

Validity: c0=1 or 2

006 -

c66 Enabling direct threshold

Validity: c0=1 or 2

-50 -50 150 °C/°F

c67 Enabling reverse threshold

Validity: c0=1 or 2

150 -50 150 °C/°F

“Reverse” control with enabling of “direct” logic:

Looking at the example of a controller with two outputs, one of which

ON/OFF and the other 0 to 10 Vdc. When the temperature read by probe

B2, if c19=5, or the di erence B2-B1, if c19=6, exceeds the threshold c66

(plus an hysteresis of 1.5°C to avoid swings), control is enabled on St1 and

P1; below this temperature, control is disabled.

“Direct” control with enabling of “reverse” logic:

In this case too, a controller with two outputs, one of which a ON/OFF

and the other 0 to 10 Vdc. When the temperature read by probe B2, if

c19=5 or the di erence B2-B1, if c19=6, falls below the threshold c67

(beyond an hysteresis of 1.5°C to avoid swings), control is enabled on St1

and P1; above this temperature, control is disabled.

6.5.7 Using the CONV0/10A0 module (accessory)

This module converts a 0 to 12 Vdc PWM signal for solid state relays to a linear

0 to 10 Vdc and 4 to 20 mA analogue signal.

Programming: to get the modulating output signal, the PWM control mode is

used (see the explanation for parameter c12). The PWM signal is reproduced

exactly as an analogue signal: the percentage ON time corresponds to the

percentage of the maximum output signal. The optional CONV0/10A0 module

integrates the signal provided by the controller: the cycle time (c12) must be

reduced to the minimum value available, that is, c12=0.2 s. As concerns the

control logic (“direct”=cooling, “reverse”=heating), the same observations

seen for PWM operation apply (see mode 4): the PWM activation logic is

faithfully reproduced as an analogue signal. If, on the other hand, a custom

con guration is required, refer to the paragraphs on special operation (“type

of output”, ”activation”, “di erential/logic” parameters).

Loading...

Loading...