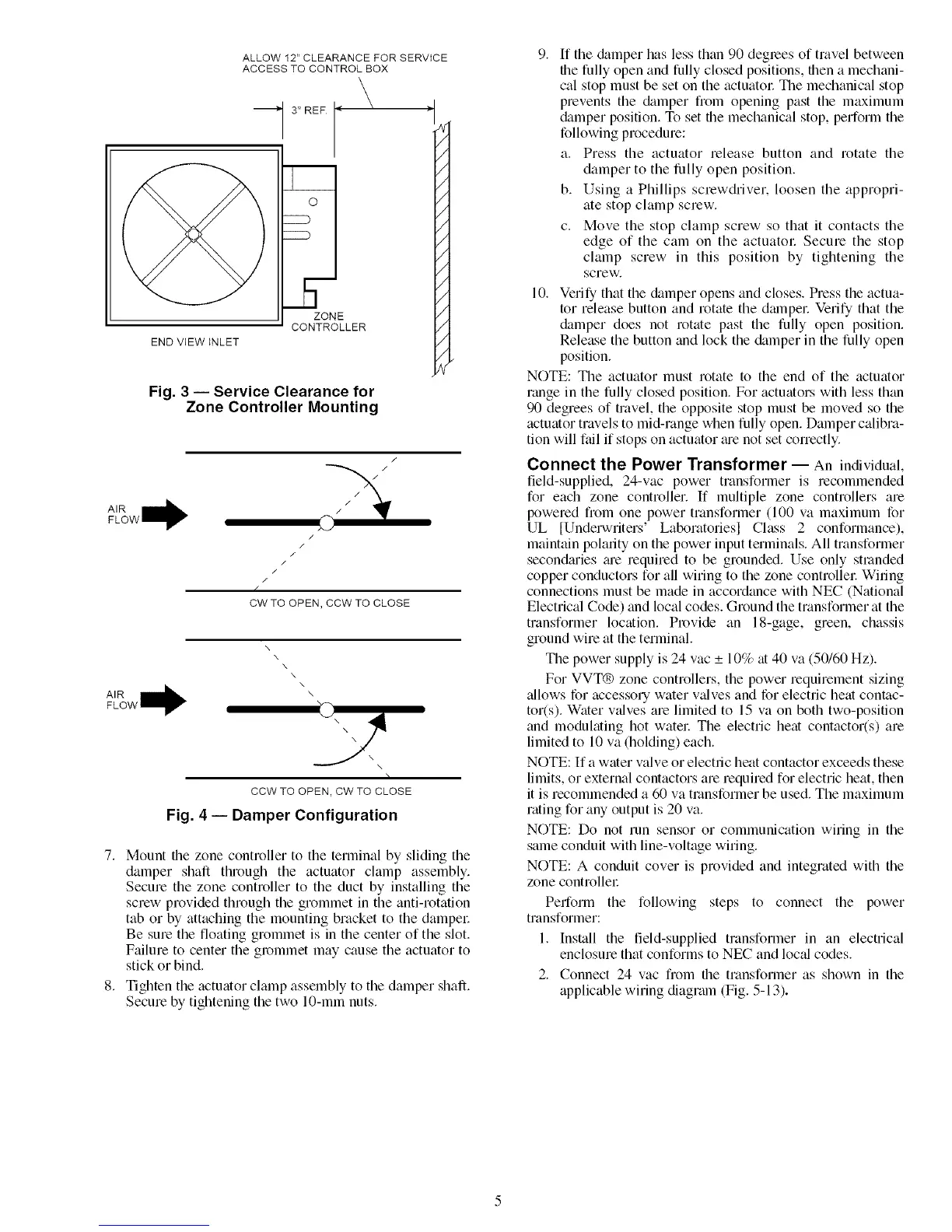

END VIEW INLET

-- 3" REF

ZONE

CONTROLLER

ALLOW 12" CLEARANCE FOR SERVICE

ACCESS TO CONTROL BOX

_lar

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

N

Fig. 3 -- Service Clearance for

Zone Controller Mounting

//

/

/

/

//

K /

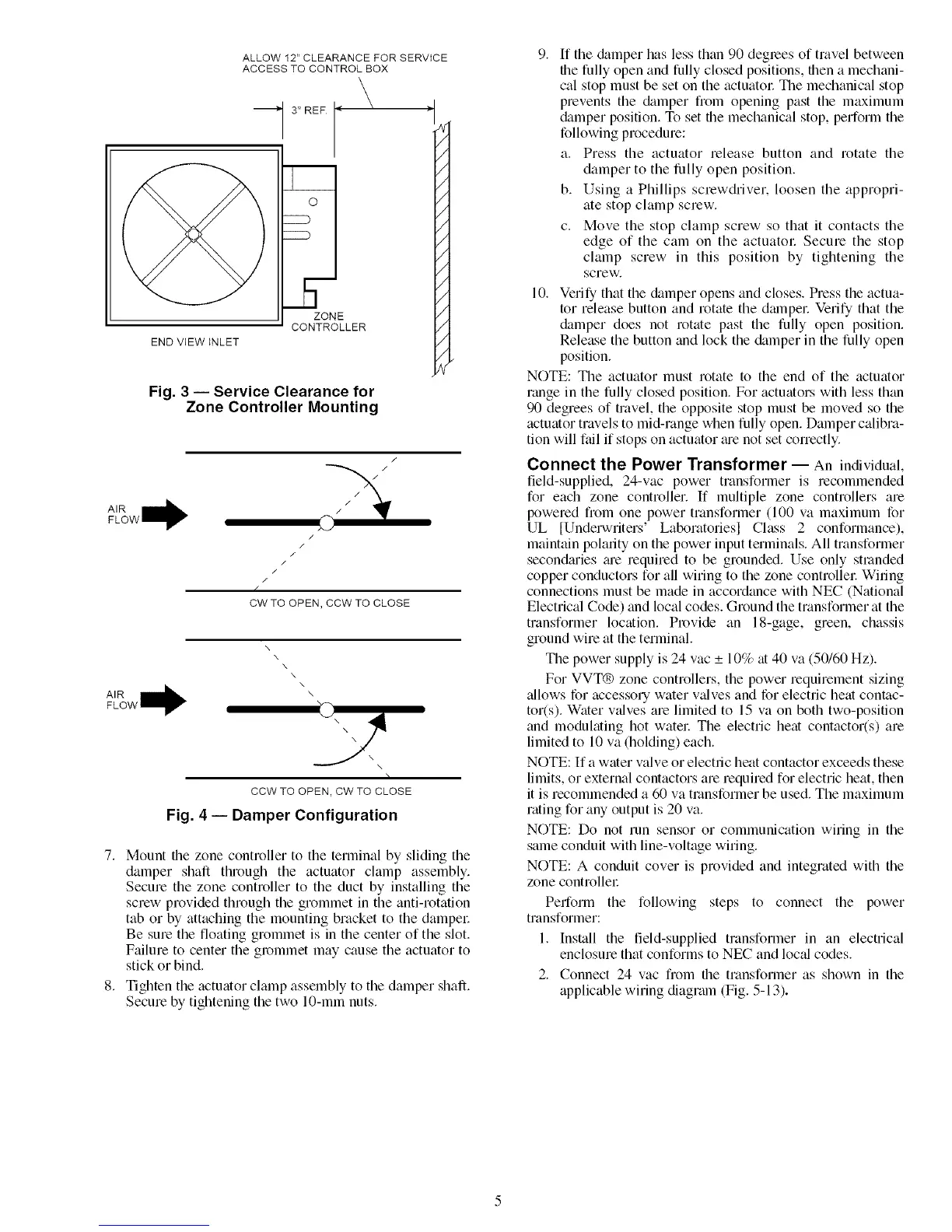

CW TO OPEN, CCW TO CLOSE

x

\

x

\

\

\

CCW TO OPEN, CW TO CLOSE

Fig. 4 -- Damper Configuration

7. Mount the zone controller to the terminal by sliding the

damper shaft through the actuator clamp assembly.

Secure the zone controller to the duct by installing the

screw provided through the grommet in the anti-rotation

tab or by attaching the mounting bracket to the dampec

Be sure the floating grommet is in the center of the slot.

Failure to center the grommet may cause the actuator to

stick or bind.

8. Tighten the actuator clamp assembly to the damper shaft.

Secure by tightening the two 10-mm nuts.

9. ff the &_mper has less than 90 degrees of travel between

the fully open and fully closed positions, then a mechani-

cal stop must be set on the actuatol: The mechanical stop

prevents the &_mper from opening past the maximum

damper position. To set the mechanical stop, perform the

following procedure:

a. Press the actuator release button and rotate the

damper to the fully open position.

b. Using a Phillips screwdriver, loosen the appropri-

ate stop clamp screw.

c. Move the stop clamp screw so that it contacts the

edge of the cam on the actuatol: Secure the stop

clamp screw in this position by tightening the

screw.

10. Verify that the &Lmper opens and closes. Press the actua-

tor release button and rotate the dmnpel: Verify that the

damper does not rotate past the fully open position.

Release the button and lock the &_mper in the fully open

position.

NOTE: The actuator must rotate to the end of the actuator

range in the fully closed position. For actuators with less than

90 degrees of travel, the opposite stop must be moved so the

actuator travels to mid-range when fully open. Damper calibra-

tion will f_dl if stops on actuator _ue not set correctly.

Connect the Power Transformer -- An individual,

field-supplied, 24-vac power transformer is recommended

for each zone controller. If multiple zone controllers are

powered fiom one power transformer (100 va maximum for

UL [Underwriters' Laboratoriesl Class 2 conformance),

maintain polarity on the power input terminals. All transformer

second;uies ;ue required to be grounded. Use only stranded

copper conductors for all wiring to the zone controllec Wiring

connections must be made in accordance with NEC (National

Electrical Code) and local codes. Ground the transformer at the

transformer location. Provide an 18-gage, green, chassis

ground wire at the terminal.

The power supply is 24 vac _+10% at 40 va (50/60 Hz).

For VVT® zone controllers, the power requirement sizing

_dlows for accessory water v_dves and for electric heat contac-

tot(s). Water v_dves are limited to 15 va on both two-position

and modulating hot watel: The electric heat contactor(s) are

limited to 10 va (holding) each.

NOTE: If a water valve or electric heat contactor exceeds these

limits, or external contactors are required for electric heat, then

it is recommended a 60 va transformer be used. The maximum

rating for any output is 20 va.

NOTE: Do not run sensor or communication wiring in the

same conduit with line-voltage wiring.

NOTE: A conduit cover is provided and integrated with the

zone controllel:

Perform the following steps to connect the power

transformer:

1. Install the field-supplied transformer in an electrical

enclosure that conforms to NEC and loc_d codes.

2. Connect 24 vac from the transformer as shown in the

applicable wiring diagrmn (Fig. 5-13).

Loading...

Loading...