73

LEGEND

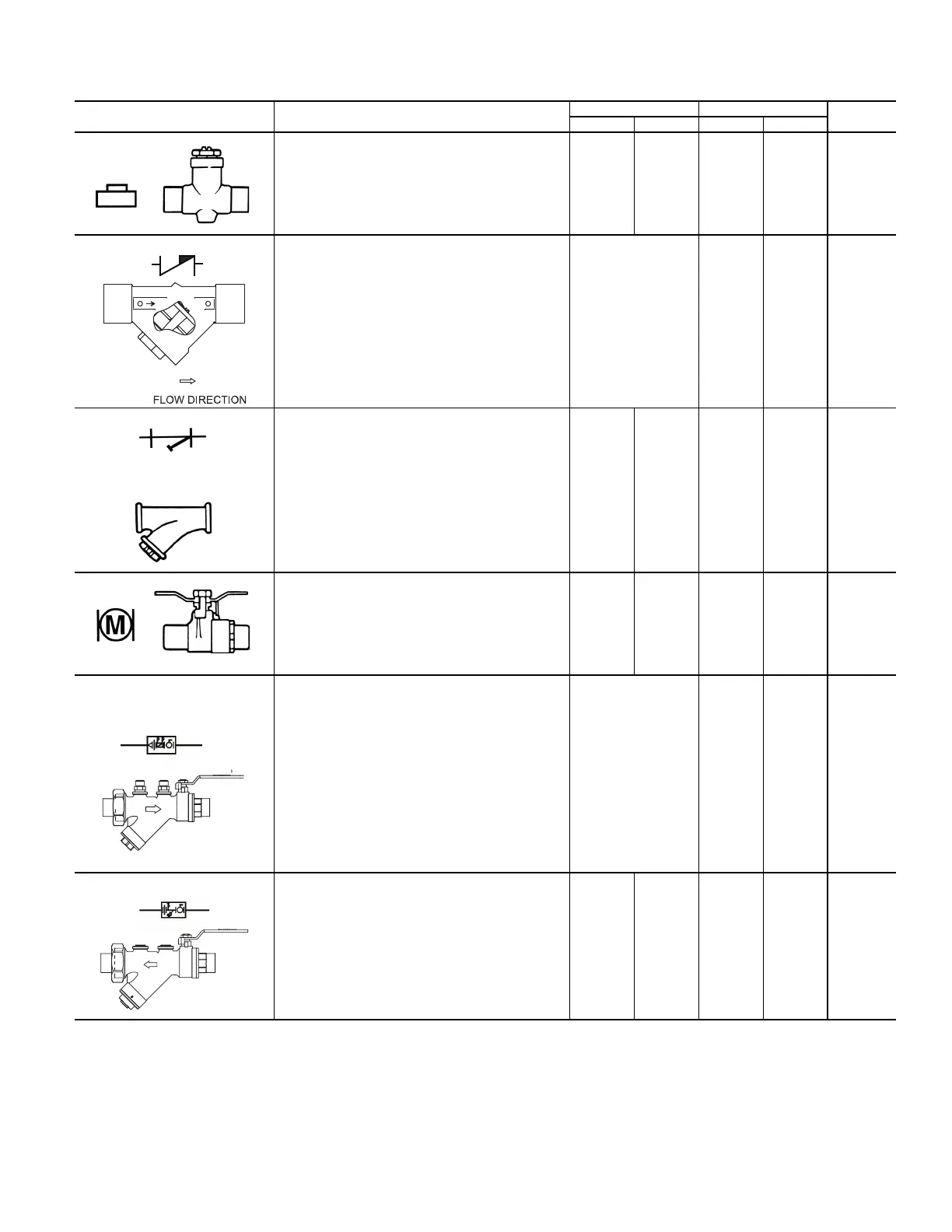

Table 7 — Piping Components (cont)

SYMBOL/SKETCH DESCRIPTION

C

V

FACTOR RATING

a

STEAM

USE

1/2 3/4 psi F

BALANCE VALVE: Variable water flow manual balancing

valve with screwdriver slot adjustment screw.

Application — May be used in 3-way valve bypass line to

permit equal flow balancing.

3 8.9 150 200 NO

FIXED FLOW VALVE: Flexible orifice type (non-adjustable).

Application — Used for water flow balancing. Valve

automatically adjusts the flow to within 10% of set point.

Operating Range: 2-80 psid

Valve orifice size

determines C

V

factor.

The orifice of these fixed

flow valves changes as

flow is regulated. As the

water pressure

increases, the orifice size

decreases, thereby

automatically limiting the

flow rate to the specified

gpm (±10%).

600 220 NO

STRAINER: Y-type body (optional with blowdown) with 20

mesh stainless steel screen.

Application — Used for removal of small particles from

system water during normal system operation. Should not

be used in lieu of main system strainers. Strainer screen

may have to be removed during initial high pressure system

flushing during start-up. Screen should be removed and

cleaned per normal maintenance schedule (provisions for

strainer blow-down not provided).

5.5

Clean

9.0

Clean

600 325 N/A

BALL VALVE WITH MEMORY STOP: Manual balance and

shut-off valve.

Application — Used for unit isolation and water flow

balancing. The adjustable memory stop feature allows return

to the balance point after shut-off. Check specifications for

service fittings required when used for water balancing.

Full Port Full Port 600 325 N/A

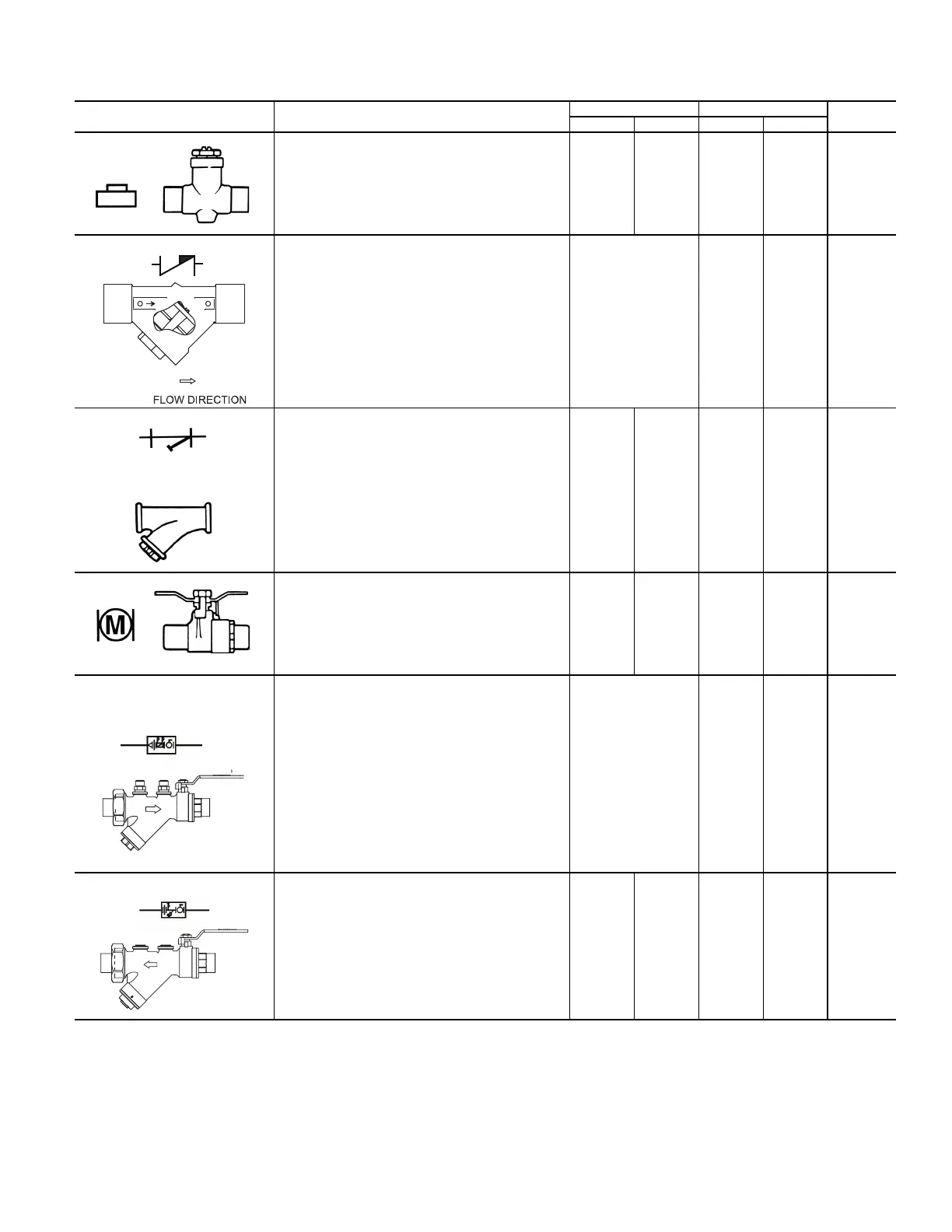

RETURN COMBO VALVE: A combination automatic flow

control valve, ball valve, and union end. Valve comes

standard with two pressure and temperature test plugs.

Application — Instead of adding individual components,

utilize the combination valve to save cost. Fixed flow used

for water flow balancing.

Valve orifice size

determines C

v

factor. The

orifices of these fixed

flow valves changes as

flow is regulated. As the

water pressure

increases, the orifice size

decreases, thereby

automatically limiting the

flow rate to the specified

GPM (± 10%).

600 220 N/A

SUPPLY COMBO VALVE: Includes union, ball valve,

y-strainer with blowdown, and P-T port.

Application — Instead of adding individual components,

utilize the combination supply valve to save cost. Y-strainer

with blowdown used for removal of small particles from

system water during normal system operation. Should not

be used in lieu of main system strainers. Strainer screen

may have to be removed during the initial high pressure

system flushing during start-up. Screen should be removed

and cleaned per normal maintenance schedule.

5.5 Clean 9.0 Clean 600 325 N/A

a. Check all system component pressure ratings (coils, values, pumps, etc.) with manufacturer and any applicable local or national piping codes prior to specifying system

pressure rating.

Cv — Coefficient of Velocity

ETO — Engineered to Order

Loading...

Loading...