13

COOLING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

This system uses PuronR re frigerant which has

higher pressures than R--22 and other refrigerants. No

other refrigerant may be used in this system. Gauge

set, hoses, and recovery system must be designed to

handle Puron refrigerant. If unsure about equipment,

consult the equipment manufacturer.

!

WARNING

Condenser Coil

The condenser coil is fabri cated with round tube copper

hairpins and plate fins of various materials and/or coatings

(see Model Number Format i n the Appendix to identify

the materials provided in this unit). The coil may be

one--row or composite--type two--row. Composite two--row

coils are two single--row coils fabricated with a single

return bend end tubesheet.

Condenser Coil Maintenance and Cleaning

Recommendation

Routine cleaning of coil surfaces is essential to maintain

proper operation of the unit. Elimination of contamination

and removal of harmful residues will greatly increase the

life of the coil and extend the life of the unit. The

following maintenanc e and cleaning procedures are

recommended as part of the routine maintenance activities

to extend the life of the coil.

Remove Surface Loaded Fibers

Surface loaded fibers or dirt should be removed with a

vacuum cleaner. If a vacuum cleaner is not available, a

soft non--metallic bristle brush may be used. In either

case, the tool should be applied in the directi on of the fins.

Coil surfaces can be easily damaged (fin edges can be

easily bent over and damage to the coating of a protected

coil) if the tool is applied across the fins.

NOTE: Use of a water stream, such as a garden hose,

against a surface loaded coil will drive the fibers and dirt

into the coil. This will make cleaning efforts more

difficult. Surface loaded fibers must be completely

removed prior to using low velocity clean water rinse.

Periodic Clean Water Rinse

A periodic clean water rinse is very beneficial for coils

that are applied in coastal or industrial environments.

However, it is very important that the water rinse is made

with a very low velocity water stream to avoid damaging

the fin edges. Monthly cleaning as described below is

recommended.

Routine Cleaning of Coil Surfaces

Periodic cleaning with TotalineR environmentally sound

coil cleaner is essential to extend the life of coils. This

cleaner is available from Replacement Components

Division as part number P902--0301 for a one gallon

conta iner, and part number P902--0305 for a 5 gallon

conta iner. It i s recomme nded that all coils, including

standard a luminum, pre--coated, copper/copper or

E--coated coils be cleaned with the Totaline

environmentally sound c oil clea ner as described below.

Coil cle aning should be part of the unit’s regularly

scheduled mai ntenance procedures to ensure long life of

the coil. Failure to clean the coils may result in reduced

durability in the environment.

Avoid use of:

S coil brighteners

S acid cleaning prior to painting

S high pre ssure washers

S poor quality water for cleaning

Totaline environme ntally sound coil cleaner is

nonflammable, hypo allergenic, non ba cterial, and a

USDA accepted biodegradable agent that will not harm

the coil or surrounding components such as electrical

wiring, painted metal surfaces, or insulation. Use of

non--recommended coil cleane rs is strongly discouraged

since coil and unit durability could be affected.

One--Row Coil

Wash coil with commercial coil cleaner. It is not

necessary to remove top panel.

Two--Row Coils

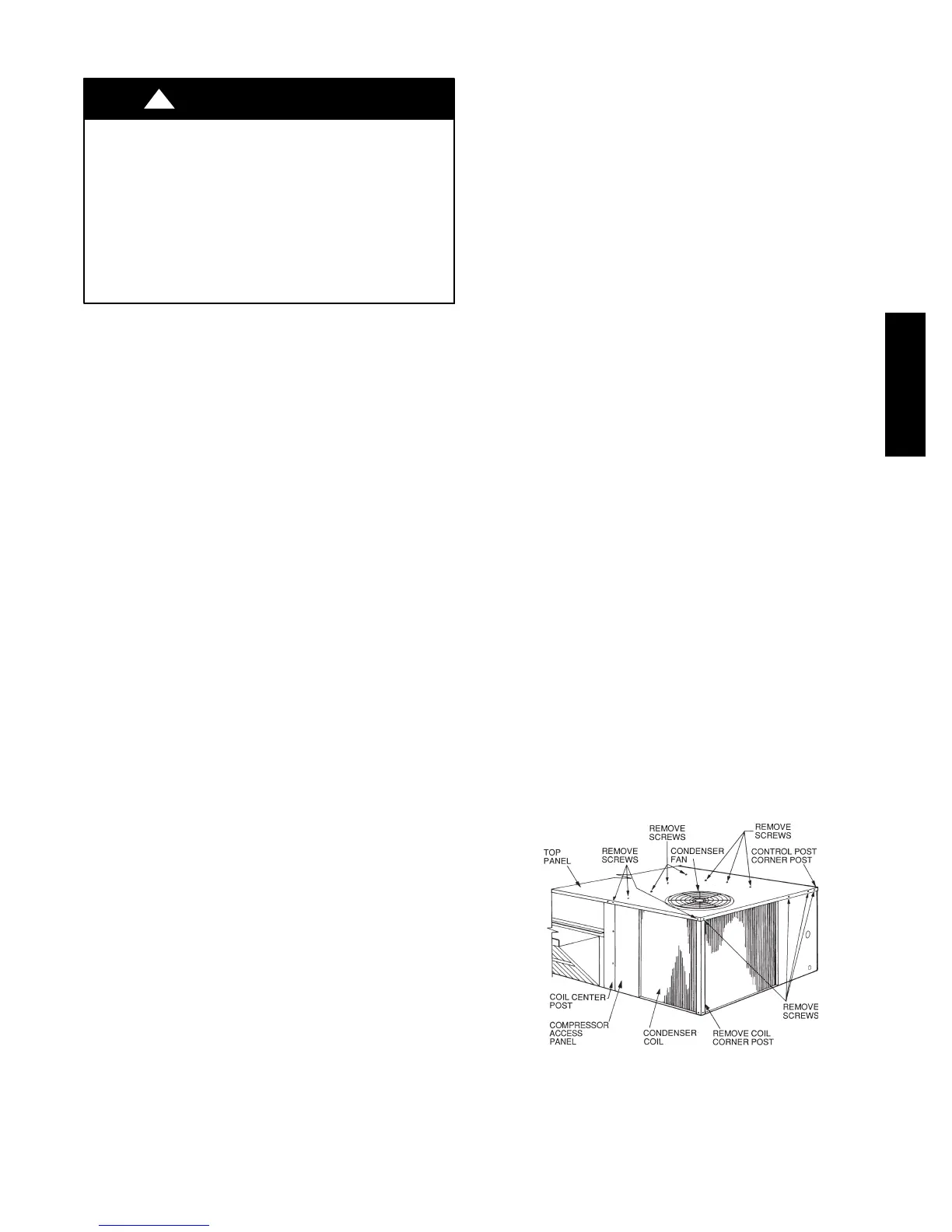

Clean coil as follows:

1. Turn off unit power, tag disconne ct.

2. Remove top pane l screws on conde nse r end of unit.

3. Remove condenser coil corner post. See Fig. 16. To

hold top panel open, place coil corner post between

top panel and center post. See Fig. 17.

C08205

Fig. 16 -- Cleaning Condenser Coil

48HC

Loading...

Loading...