11 - TECHNICAL SPECIFICATIONS

Filter fouling is measured by a pressure sensor located in the electrics box.

It is set to 1.5 times the value for the lter when clean (pressure ports upstream and downstream of the lter).

11.1.5 - Standard control elements:

(Factory cables)

- An intake temperature sensor.

- A dierential pressure sensor: attached to the electrics box, this allows the dierence in pressure upstream and downstream of

the lter to be measured, so as to determine whether the lter is fouled.

- A water leak sensor: this is found at the end of a wound cable located at the bottom of the unit so that it is long enough to extend

downwards into a raised oor, if required, and to be positioned in the area to be monitored. It can be added on request.

It can be added on request.

11.2 - Optional Components

11.2.1 - Heating coil

Moderately tighten the "coil supply" connections to avoid damaging the manifolds.

The coil is adjusted by a two-way or four-way valve equipped with a 0-10V servomotor (mounted and connected).

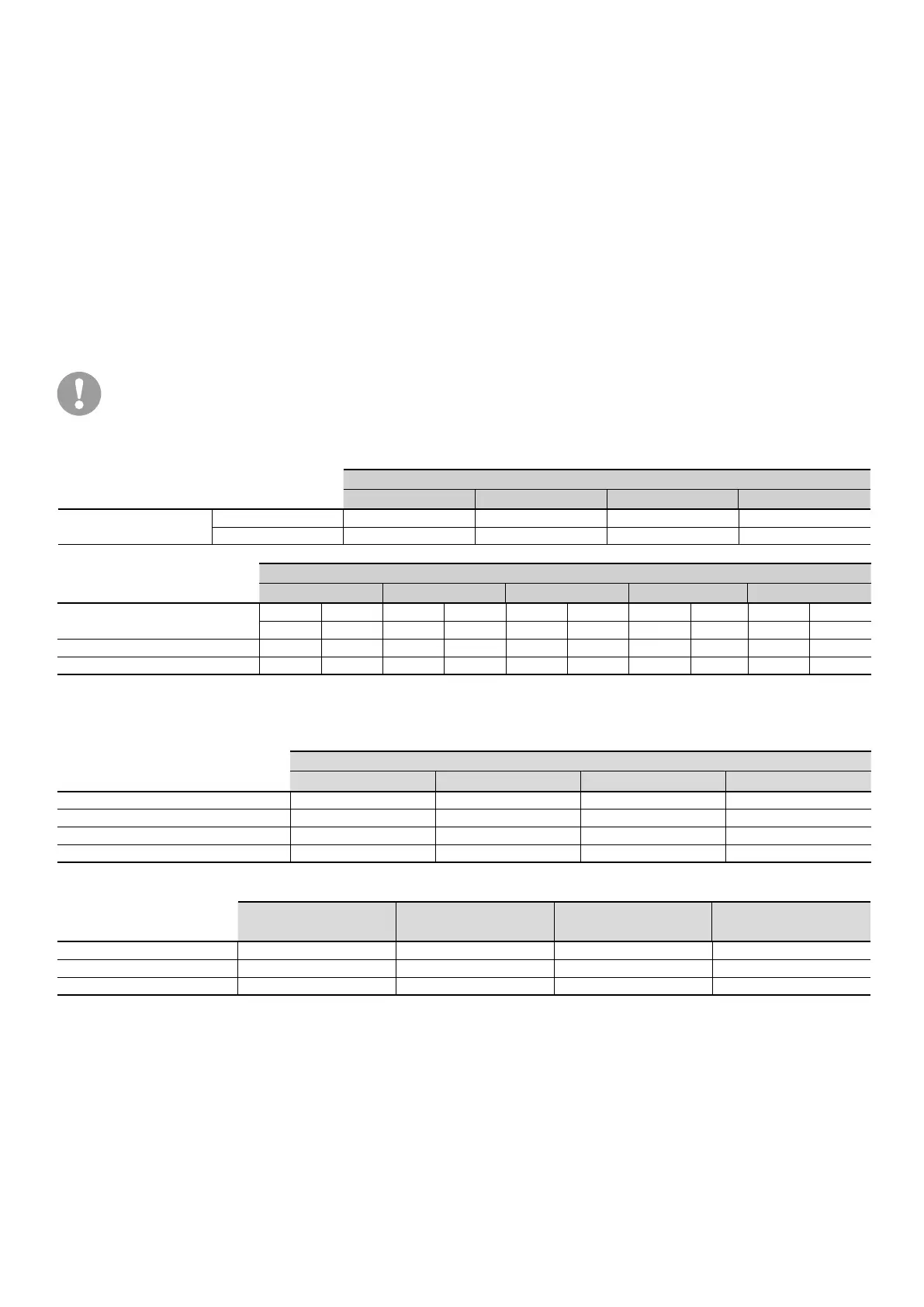

Coil specications:

HOT WATER

W40 W53 W78 W100

Coil (1 row)

Number of coils 1 1 1 1

Capacity (l) 3,82 4,92 6,29 6,29

HEATING COIL

W40 W53 W78 W100 W115

Air ow (m3/h)

Nominal Maximum Nominal Maximum Nominal Maximum Nominal Maximum Nominal Maximum

10 000 13 300 13 300 13 300 18 800 20 500 24 500 27 000 27 000 27 500

Heating capacity (kW)* 36 40 44 44 63 66 71 73 - -

Heating capacity (kW)** 18 21 23 23 33 34 37 38 - -

* Conditions: return air 17 °C - 50 %, water temperature 80/60 °C

** Conditions: return air 17 °C - 50 %, water temperature 45/40 °C

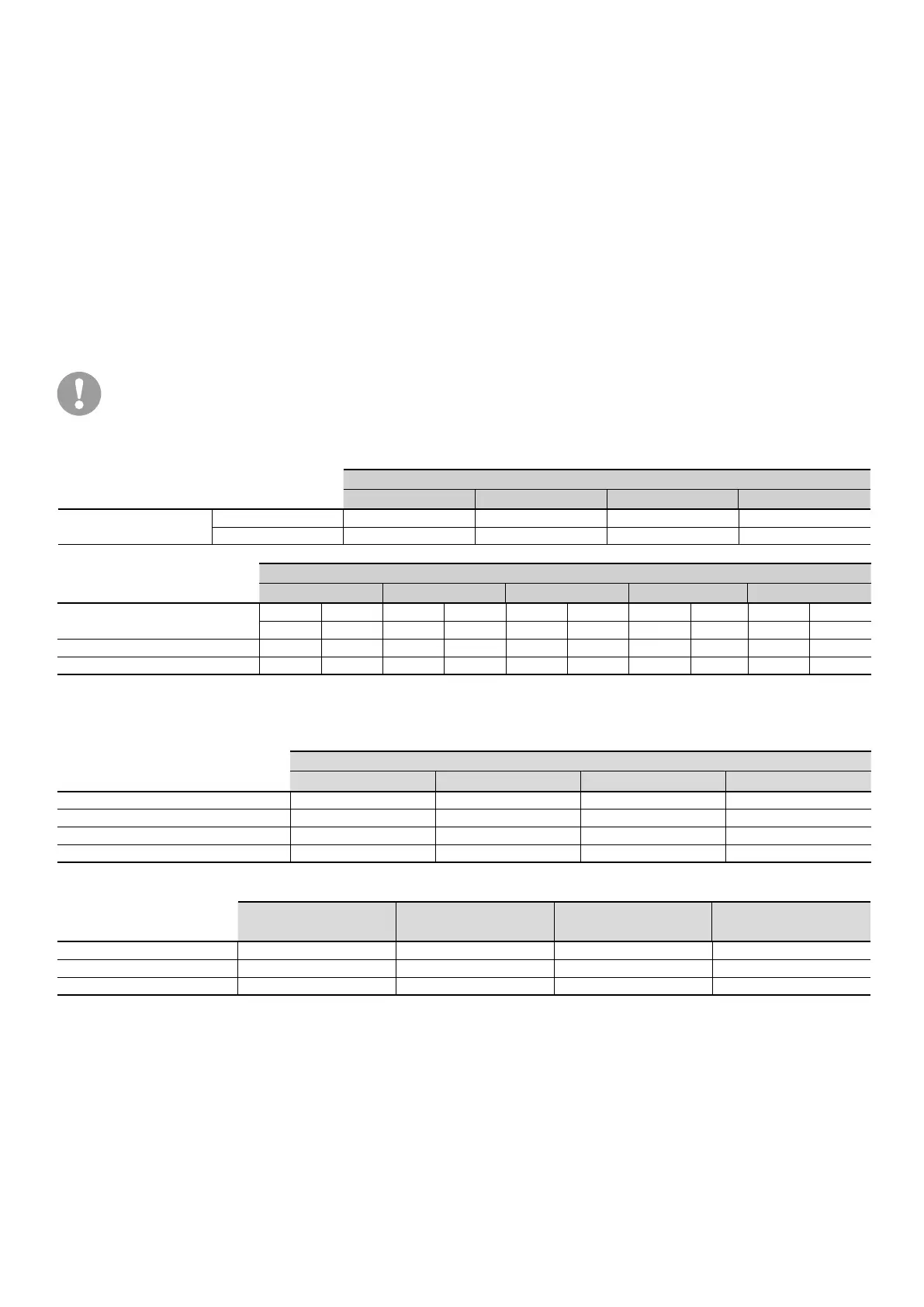

Heating coil pressure drop*:

HOT WATER

W40 W53 W78 W100

Nominal water ow (m³/h) 0,9 1,1 1,68 1,9

KV valve 4 4 4 4

∆P Valve only (mWC) 0,6 0,8 1,8 2,3

∆P (Pa) Valve + Coil (mWC) 1,5 1,8 3 3,8

Nominal ow rate: water ∆T: 20 °C

W40 W53 W78 W100

KV 4 4 4 4

∆P max.¹ Four-way valve 240 240 240 240

∆P max.² Two-way valve 400 400 400 400

15

Loading...

Loading...