Do you have a question about the Carrier Touch Pilot and is the answer not in the manual?

Provides a broad overview of the Touch Pilot control system for 61XWHZE heat pumps.

Lists frequently used abbreviations for components and terms within the manual.

Essential guidelines for safe installation, start-up, and servicing of equipment.

Precautions regarding electrical components, hot parts, and proper handling.

How the Touch Pilot system controls and monitors heat pumps for optimal performance.

Overview of components managed by the controller for effective unit operation.

Explanation of Local, Remote, and Network modes for unit control.

Details on SIOB, TCPM, AUX1, EMM boards and internal LEN bus communication.

Information on the 24 VAC power supply and LED indicators for board status.

Details on controller connections (RS485, Ethernet) and sensor types.

Description of pressure transducers and temperature sensors for monitoring.

Description of actuators like pumps, EXV, and the water flow switch function.

Overview of connections at the user terminal block, varying by options.

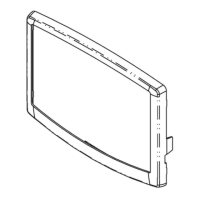

Introduction to the 5-inch touch screen interface and navigation methods.

Explanation of Home, Menu, Login, Start/Stop, Alarm, and Navigation buttons.

Description of the Welcome screen, software version, and information message box.

Overview of the Synoptic screen for monitoring the refrigeration cycle and unit status.

Instructions for starting and stopping the unit via the Local off mode interface.

User login, password change, display language, and measurement system settings.

Access to general parameters, inputs, outputs, and other main control parameters.

Access to user-modifiable parameters like pump config, schedule, and user settings.

Option to override system configuration for specific parameters via the data screen.

Instructions to access the Touch Pilot control via a web browser using the unit's IP address.

Minimum browser configuration settings for accessing the web interface.

How to find and access unit technical documents through the web interface.

Overview of main menu icons, displayed text, descriptions, and associated tables.

Detailed listing of general unit parameters and their descriptions.

Detailed listing of temperature parameters and their descriptions.

Detailed listing of pressure parameters and their descriptions.

Detailed listing of input parameters and their descriptions.

Detailed listing of output parameters and their descriptions.

Detailed listing of pump status and runtime parameters.

Detailed listing of operating modes and their descriptions.

Detailed listing of setpoint parameters and their descriptions.

Configuration of circuit priority, loading sequences, and unit settings.

Configuration options for condenser and evaporator pumps, including sequence and delays.

Settings for user password management and access levels.

Configuration for cooling and heating reset source selection and values.

Setting unit start/stop schedules and defining holiday periods.

Configuration for outdoor air temperature broadcast and date/time settings.

Parameters for identifying the unit, such as CCN element number and software version.

Options to reset active alarms and view current, historical, and major alarms.

Factors determining unit state, operating types, and start/stop commands.

How the unit reduces compressor capacity before stopping due to alarms or demands.

Management of cooling/heating modes, selection, and setpoint control.

Function of the control interlock contact and active setpoint selection.

Selection of active setpoints for cooling and heating based on occupancy and ice storage.

Modifying setpoints based on delta T, 4-20mA signals, or space temperature.

Configuration and control of cooler and condenser pumps.

Automatic daily pump start feature to prevent sticking and maintain pump health.

Limiting unit capacity via contacts, lag limit, night mode, or network demand.

Configuring specific parameters and capacity limits for night period operation.

Managing current limitation via demand limit function to protect compressors.

Adjusting unit capacity using the slide valve to maintain water temperature setpoint.

Determining lead/lag circuits for dual units via automatic or manual selection.

Managing circuit capacity loading and unloading using staged or smart sequences.

Setting the maximum condenser leaving water temperature for high condensing units.

Controlling condensing pressure using a three-way valve option.

Linking units into a master/slave assembly for coordinated control and operation.

Controlling energy consumption and monitoring unit/compressor status with EMM.

Configuring unit start/stop and setpoint schedules for different occupancy periods.

Visualizing unit operations and monitoring selected parameters using graphs.

Displaying unit status, alarm indicators (blinking/highlighted bell), and accessing alarm info.

Setting up email notifications for new alarms or alarm resets.

Accessing and viewing a list of up to 10 currently active alarms.

Methods for automatically or manually resetting alarms via the interface.

Accessing historical data of resolved alarms through the Alarm history menu.

Comprehensive table of alarms, reset types, actions, and potential causes.

Recommends activating a contract for regular inspections and optimal equipment operation.

| Brand | Carrier |

|---|---|

| Model | Touch Pilot |

| Category | Control Unit |

| Language | English |