6

3 - HARDWARE DESCRIPTION

3.1 - Control boards

manage all inputs and outputs of the controller. TCPM board

is used to control and protect the operation of screw

detection option. At the same time, Energy Management

Module (EMM) requires an additional SIOB board to be

accordingly starts the program that controls the unit.

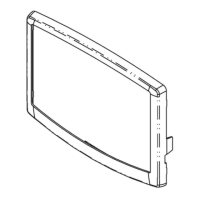

The unit is equipped with the Touch Pilot user interface

(5-inch colour LCD touch screen).

The electrical box includes all boards controlling the unit

and the user interface.

3.2 - Power supply to boards

All boards are supplied from a common 24 VAC supply

referred to earth.

CAUTION: Maintain correct polarity when connecting the

power supply to the boards, otherwise the boards may be

damaged.

automatically without the need for an external command.

the unit from restarting.

3.3 - Connections of the main controller

Connections are located on the bottom side of the main

controller.

port is used to connect to CCN (Carrier Comfort Network)

and the second RS485 port is used for internal communication

(LEN).

The Ethernet port allows for TCP/IP communication or BMS

(Building Management System) connection thanks to

BACnet/IP communication.

Connections of the main controller:

1 USB connector

2 Ethernet connector

3 CCN connector

4 LEN connector (RS485)

5 Power supply (24 VAC)

3.4 - Light emitting diodes on boards

All boards continuously check and indicate the proper

operation of their electronic circuits. A light emitting diode

(LED) lights on each board when it is operating properly.

•

SIOB board indicates correct operation. A different

rate indicates a board or a software failure.

•

indicates a LEN bus wiring problem.

3.5 - Pressure transducers

Two types of electronic sensors (high and low pressure) are

connected to the SIOB board.

Discharge pressure sensors (high pressure type)

These sensors measure the discharge pressure in each circuit.

They are used to control head pressure or high pressure load

shedding. Discharge pressure sensors are mounted on the

discharge line piping of each circuit.

Suction pressure sensors (low pressure type)

These sensors measure the suction pressure in each circuit.

They are used for control. Suction pressure sensors are located

on the suction piping of each circuit.

Oil pressure sensors (high pressure type)

These sensors measure the oil pressure of each compressor.

Oil pressure sensors are located at the oil port of the

compressor. The economizer pressure is subtracted from this

Economizer pressure sensors (high pressure type)

These sensors measure the intermediate pressure between

high and low pressure. They are used to control the economizer

performance.

3.6 - Temperature sensors

Temperature sensors constantly measure the temperature of

operation of the system.

Evaporator entering and leaving water temperature sensors

box. They are used for capacity control and safety purposes.

Condenser entering and leaving water temperature sensors

temperatures on the condenser side.

Suction gas temperature sensor

This sensor is used to control the suction gas temperature.

It is located at the suction line of each compressor.

Discharge gas temperature sensor

This sensor is used to control the discharge gas temperature,

and permits control of the discharge superheat temperature.

It is located at the discharge line of the compressor.

Oil temperature sensor

This sensor is used to control the oil temperature of each

compressor.

1 2 43

5

Loading...

Loading...