5 - ELECTRICAL CONNECTION

Please refer to the certied dimensional drawings, supplied with

the unit.

5.1 - Power supply

The power supply must conform to the specication on the unit

nameplate. The supply voltage must be within the range specied

in the electrical data table. For connection details refer to the wiring

diagrams.

WARNING: Operation of the unit with an improper supply voltage or

excessive phase imbalance constitutes abuse which will invalidate

the Carrier warranty. If the phase imbalance exceeds 2% for

voltage, or 10% for current, contact your local electricity supplier

at once and ensure that the unit is not switched on until corrective

measures have been taken.

5.2 - Voltage phase imbalance (%)

100 x max. deviation from average voltage

Average voltage

Example:

On a 400 V - 3 ph - 50 Hz supply, the individual phase voltages

were measured to be:

AB = 406 V; BC = 399 V; AC = 394 V

Average voltage = (406 + 399 + 394)/3 = 1199/3

= 399.7 say 400 V

Calculate the maximum deviation from the 400 V average:

(AB) = 406 - 400 = 6

(BC) = 400 - 399 = 1

(CA) = 400 - 394 = 6

The maximum deviation from the average is 6 V. The greatest

percentage deviation is: 100 x 6/400 = 1.5 %

This is less than the permissible 2% and is therefore acceptable.

5.3 - Power connection/disconnect switch

30XW-V/30XWHV 580-880 units have one connection point

30XW-V/30XWHV 1150-1710:

• Standard unit: two connection points

• Unit with option 81: one connection point.

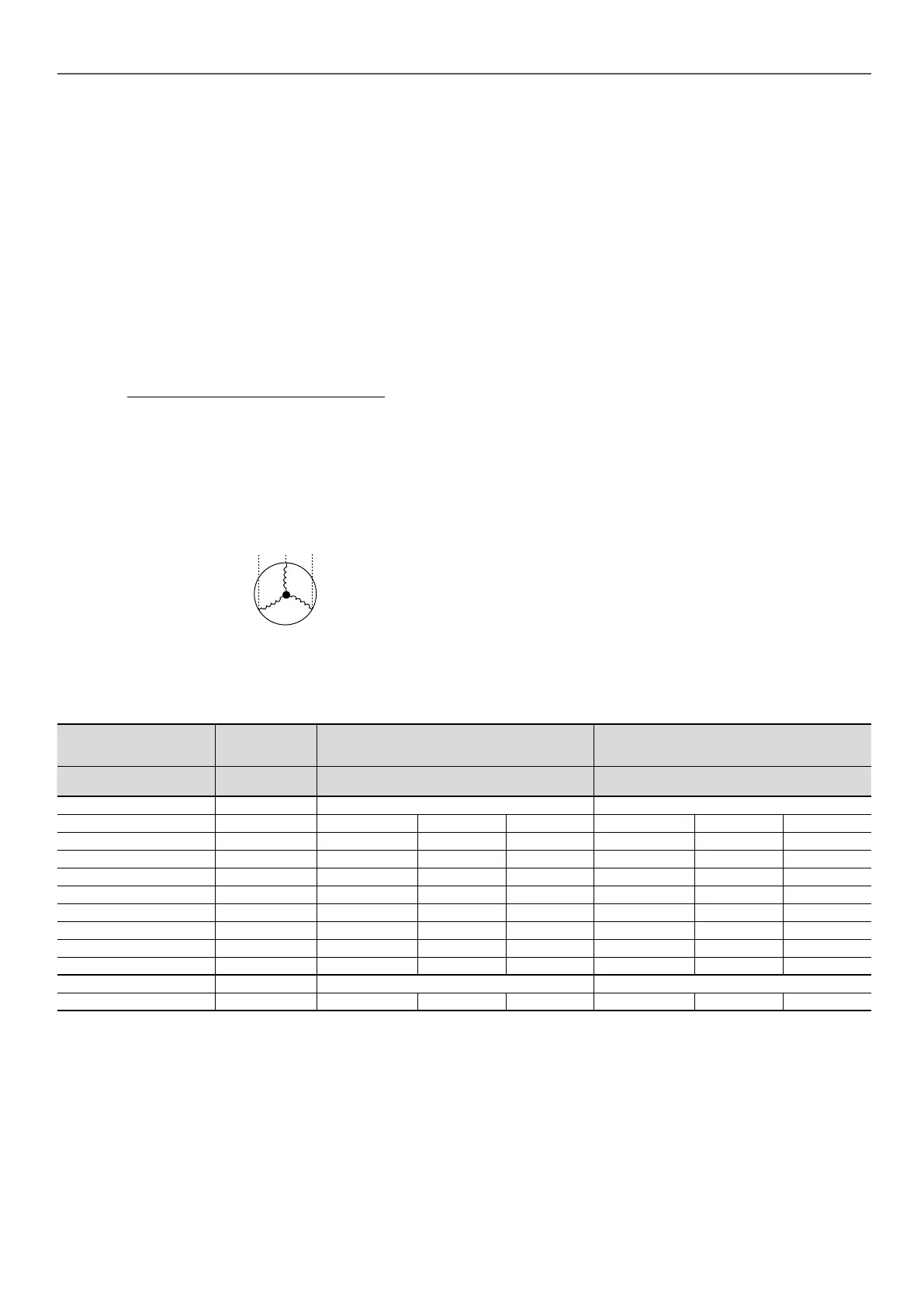

5.4 - Recommended wire sections

Wire sizing is the responsibility of the installer, and depends on the

characteristics and regulations applicable to each installation site.

The following is only to be used as a guide-line, and does not make

in any way liable. After wire sizing has been completed, using the

certied dimensional drawing, the installer must ensure easy

connection and dene any modications necessary on site. The

connections provided as standard for the eld-supplied power entry

cables to the general disconnect/isolator switch are designed for

the number and type of wires, listed in the second column of the

table below.

The calculations for favourable and unfavourable cases are based

on the maximum current for each unit (see electrical data tables).

For the design the standardised installation methods in accordance

with IEC 60364 are used: multicon-ductor PVC (70°C) or XLPE

(90°C) insulated cables with copper core; arrangement to comply

with table 52c of the above standard. The maximum temperature is

42°C. The given maximum length is calculated to limit the voltage

drop to 5%.

5.5 - Power cable entry

The power cables can enter the control box from above the unit.

A removable aluminium plate on the upper part of the control box

face allows introduction of the cables. Refer to the certified

dimensional drawing for the unit.

Minimum and maximum connectable wire sections

Max.

connectable

wire section

(1)

Calculation favourable case: Perforated

horizontal conduit (standardised routing No.

13) - XLPE insulated cable

Calculation unfavourable case: Closed

conduit (standard-ised routing No. 41) - PVC

insulated cable, if possible

30XW-V/30XWHV

Circuit(s) A/B

Section, mm²

(per phase)

Section

(2)

, mm²

(per phase)

Max. length,

m

Cable type Section

(2)

, mm²

(per phase)

Max. length,

m

Cable type

(3)

Units without option

580 2 x 240 1 x 120 250 XLPE 1 x 240 420 PVC

630 2 x 240 1 x 150 250 XLPE 2 x 150 450 PVC

810 2 x 240 1 x 185 250 XLPE 2 x 185 450 PVC

880 2 x 240 1 x 240 280 XLPE 2 x 240 480 PVC

1150 2 x 240/2 x 240 1 x 120/1 x 120 250/250 XLPE 2 x 150/2 x 150 520 PVC

1280 2 x 240/2 x 240 1 x 150/1 x 150 250/250 XLPE 2 x 185/2 x 185 510 PVC

1470 2 x 240/2 x 240 1 x 240/1 x 150 310/250 XLPE 2 x 240/2 x 185 520/510 PVC

1570 2 x 240/2 x 240 1 x 240/1 x 240 310/310 XLPE 2 x 240/2 x 240 530/530 PVC

1710 2 x 240/2 x 240 1 x 240/1 x 240 280/280 XLPE 2 x 185/2 x 185 400/400 XLPE

Units with option 81

1150 to 1710 4 x 240 2 x 240 280 XLPE 4 x 185 320 XLPE

(1) Connection capacities actually available for each machine, dened according to the connection terminal size, the control box access opening size and the available

space inside the control box.

(2) Selection simultation result considering the hypothesis indicated.

(3) If the maximum calculated section is for an XLPE cable type, this means that a selection based on a PVC cable type can exceed the connection capacity actually

available. Special attention must be given to the selection.

Note: The currents considered are given for a machine equipped with a hydraulic module operating at maximum current.

Motor

A

B

C

15

Loading...

Loading...