6 - FIELD OPERATION

228

13. To restart a Combine after a “quick stop”, start

the engine and allow it to warm up enough to run

normally and evenly. Move the engine speed

control to the low idle position. Execute Step A

and then Step B as quickly as possible in

sequence:

A. Move the separator switch to the ON

position.

B. Move the engine speed control to the

forward or full-speed position to get all

components up to speed and then reduce

engine speed to 1/2 throttle so machine can

clean itself out.

14. If the rotor is choked you will have to use the

appropriate procedure to clear it.

15. When the separator has operated long enough to

be cleared, return the engine speed control to

the low idle position, activate the feeder clutch

switch and immediately return the engine to full

speed.

Be sure to use the uniform spread column and select

the crop you are harvesting. The number shown in

this column is the number of seeds per square foot to

equal one bushel per acre loss. This number is

divided into the number of kernels you found to come

up with the bushel per acre preharvest loss.

390L8

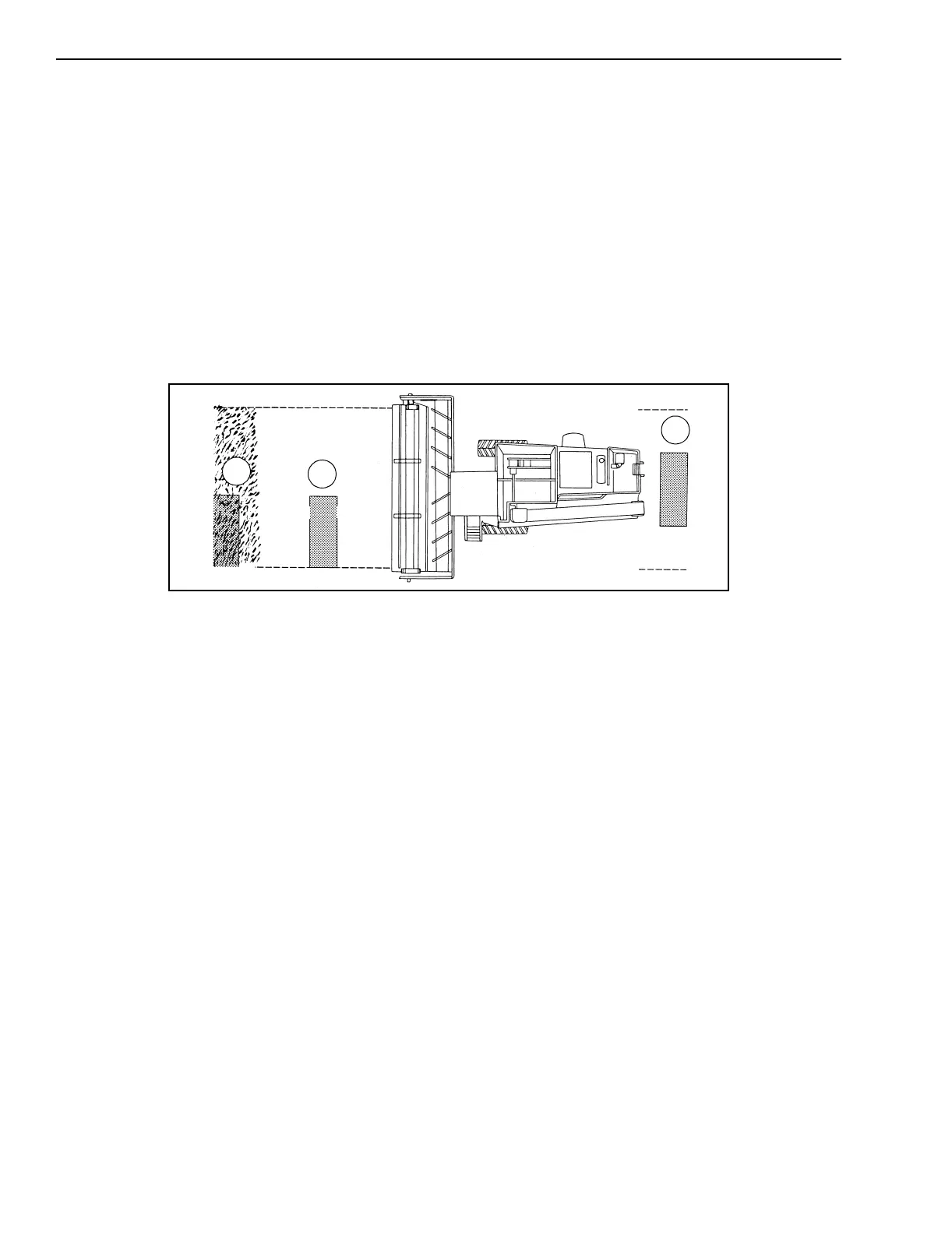

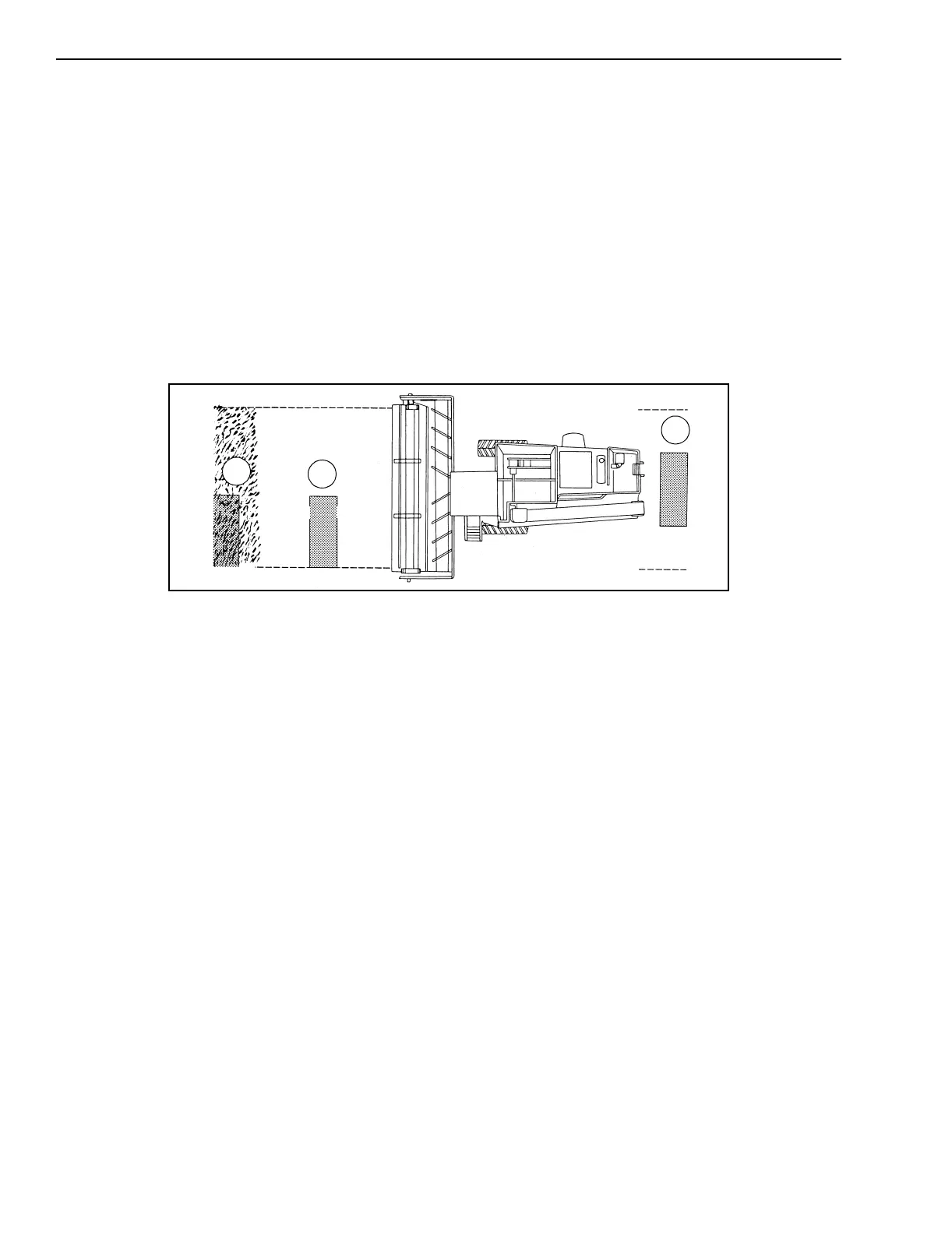

Header Losses

Header loss is due to cutting too high, reel shatter,

snapping roll loss, etc. This can be measured by

comparing the kernels on the ground in Area “B” to

Area “A”. The difference would be due to header

losses. If a more precise measurement is required,

refer to the seed loss tables and determine seed loss

the same as you did for preharvest losses, then

subtract the preharvest loss to obtain the header

loss.

Loss in Area “B” - Loss in Area “A” = Header Loss

To reduce header losses, make sure the header is

adjusted properly as explained in the Header

Operator’s Manual.

1. AREA “A’ 2. AREA “B’” 3. AREA “C”

1

2

3

Loading...

Loading...