4

FIG. A

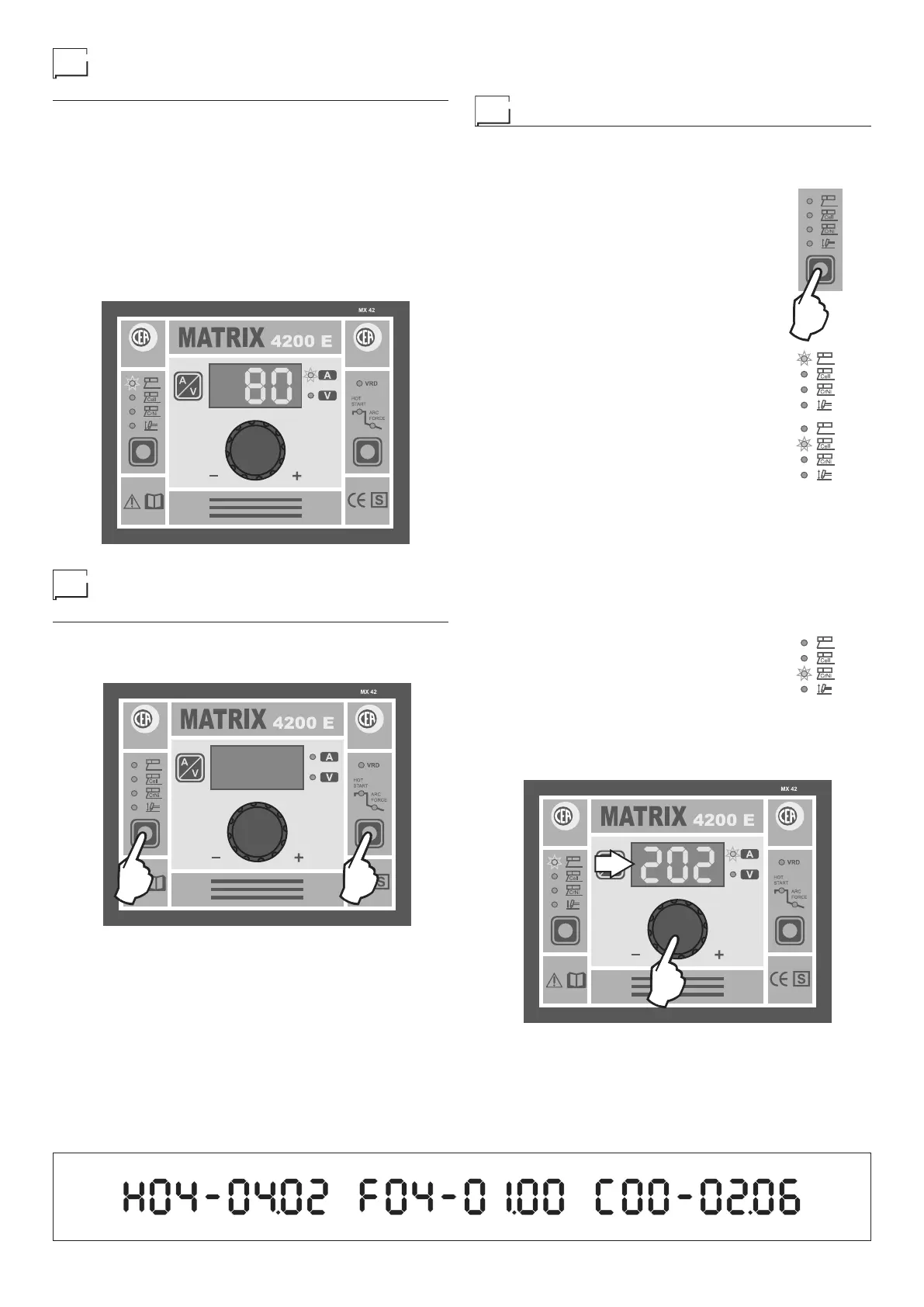

Switching on the welding

machine and initial screen

1) Start the welding machine by pushing the switch on the

rear panel to position I.

2) The welding machine carries out a short MACHINE CHECK

(all the LEDs switch on and off, one at a time, following a

preset, established start-up procedure. Then the display

shows the following message “---”).

3) Next the control panel display’s the INITIAL SCREEN for

the machine, which is then ready to weld, and the DISPLAY

shows the last numerical value set (example: 80) for the

CURRENT. Remember that since the welding machine is

in stand-by mode this value (in Amps) is not real but is the

setting.

2000HA87

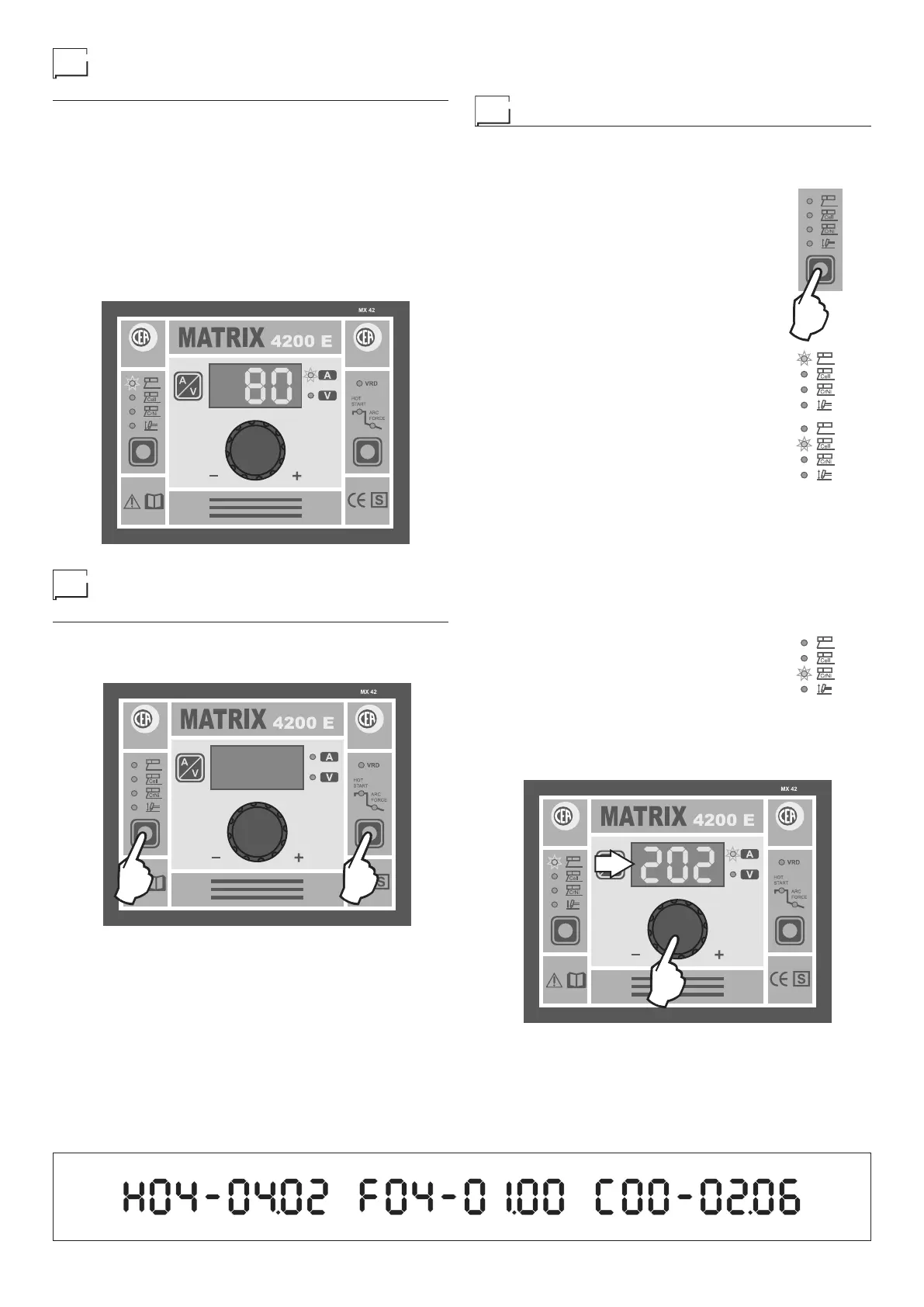

Displaying the software

version installed

1) When the welding machine is running, hold the WELDING

PROCESS SELECTION key (T1) and FUNCTION SELEC-

TION key (T2) down simultaneously, for at least 3 seconds.

T1 T2

2000HA87

2) The DISPLAY continuously runs the message shown in Fig-

ure A, indicating the SOFTWARE VERSION INSTALLED

on the welding machine, until the two-key combination is

pushed again. In detail, the meaning is as follows:

•

H04-04.02 indicates the version of HARDWARE in-

stalled.

•

F04-01.00 indicates the version of FIRMWARE installed.

• C00-02.06 indicates the version of WELDING CURVES

installed.

MMA welding (Electrode)

1) Start the welding machine by pushing the switch on the

rear panel to position I.

2) Push the WELDING PROCESS SELEC-

TION key to select one of the 3 electrode

welding processes according to the elec

-

trode material you are using:

• ELECTRODE

For welding with coated electrodes: Rutile,

basic, cast iron, and aluminium.

• Cellulose ELECTRODE

For welding with cellulose electrodes.

NOTE: Only valid for the MATRIX 2700 E - 2700 E SV welding

machines. In order to optimise fusion and the stability of the cel-

lulose electrode weld, the welding machine automatically acti-

vates a booster in this position only, which provides the welding

machine with further power. This booster works at a MAX cur-

rent of up to 130 A. We therefore recommend using cellulose

electrodes for welding with currents up to 130 A. Once this val-

ue is exceeded the booster is deactivated automatically, and so

instability and interruptions in the arc may occur.

• Stainless steel ELECTRODE

For welding stainless steel. Thanks to the

special dynamic characteristic it is possible

to weld with a soft, extremely stable arc in

order to achieve high quality welds.

3) Turn the ENCODER Knob (E) until the DISPLAY shows

the CURRENT VALUE at which you wish to weld, in rela-

tion to the diameter of the electrode you are using.

E

D

2000HA90

Loading...

Loading...