5

4) To improve the quality of the welding the following acces-

sory functions are available that relate to the MMA weld-

ing process selected:

•

HOT START - This increases the welding current, in per-

centage terms, for a time interval that can be set at the

start of the welding process, thereby reducing the risk of

poor fusion at the start of the joint (HOT START - 0-100

- regulation step: 1).

•

ARC FORCE MMA - Regulates, in percentage terms, the

dynamic characteristics of the arc (ARC FORCE - 0-100

- regulation step: 1).

WARNING: Both the values for the accessory functions are

pre-set at a value of 50, which is the value deemed best for

welding.

To select these two accessory functions, simply press the

FUNCTION SELECTION key (T2) and regulate the value us-

ing the ENCODER Knob (E).

E

T2

2000HA90

5) Once the all the selections/regulations indicated above

have been made, welding can begin.

TIG welding

1) Start the welding machine by pushing the switch on the

rear panel to position I.

2) Press the WELDING PROCESS SELEC-

TION Key and select the following pro-

cess:

• TIG with “Lift” type ignition

With TIG welding using the innovative “Lift”

type thermally controlled ignition TCS), ig-

nition come about precisely and quick-

ly, reducing the inclusions of tungsten to

a minimum and doing away with incisions

into the workpiece to be welded. The SWS

(Smart Welding Stop) system avoids oxida-

tion of the welded joint.

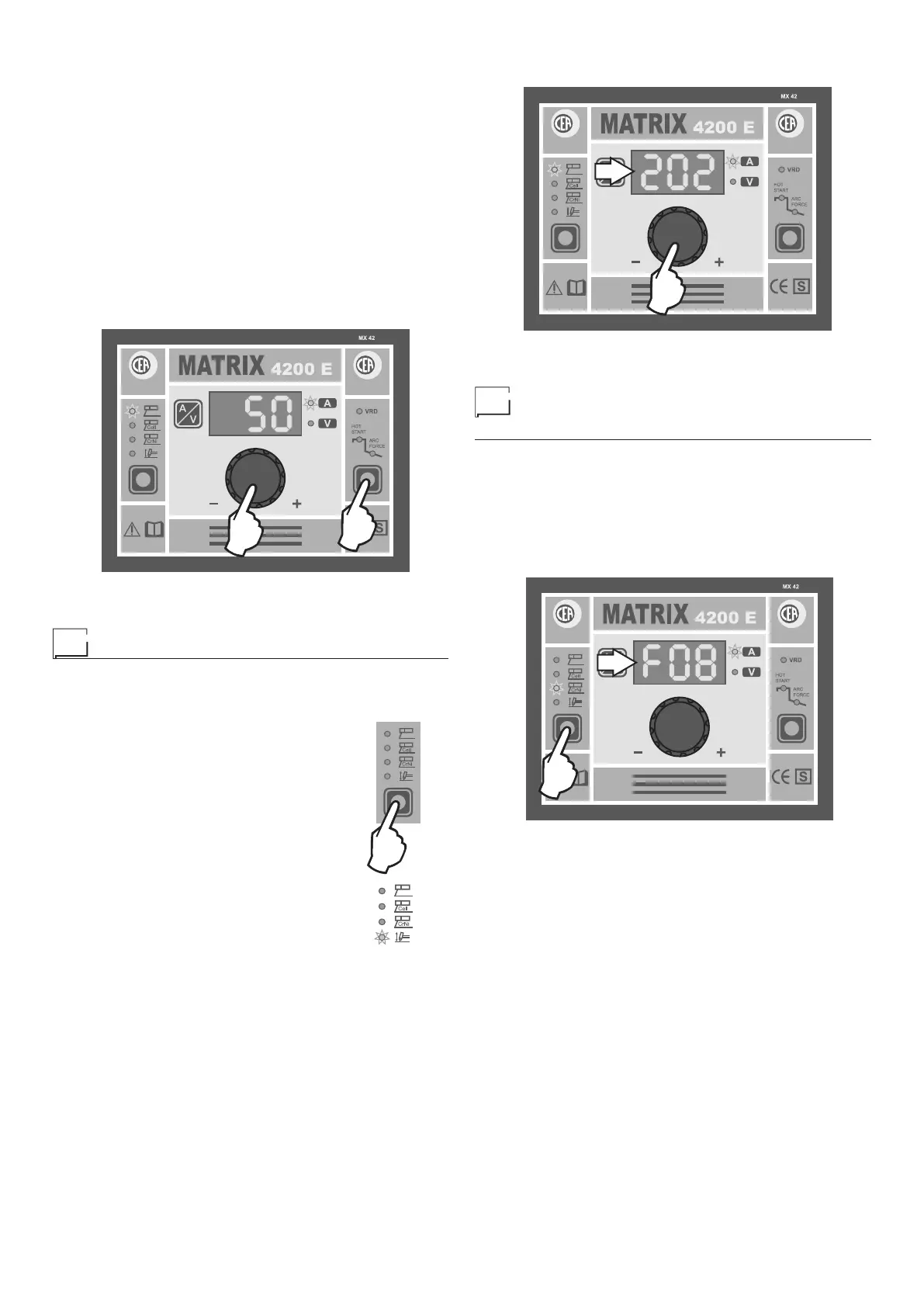

3) Turn the ENCODER Knob (E) until the DISPLAY shows

the CURRENT VALUE at which you wish to weld.

E

D

2000HA90

4) Once the all the selections/regulations indicated above

have been made, welding can begin.

Creating and memorising

automatic welding points

Once you have defined the parameters that characterise a new

automatic welding point (abbreviated as JOB), it can be stored

in the memory in the following manner:

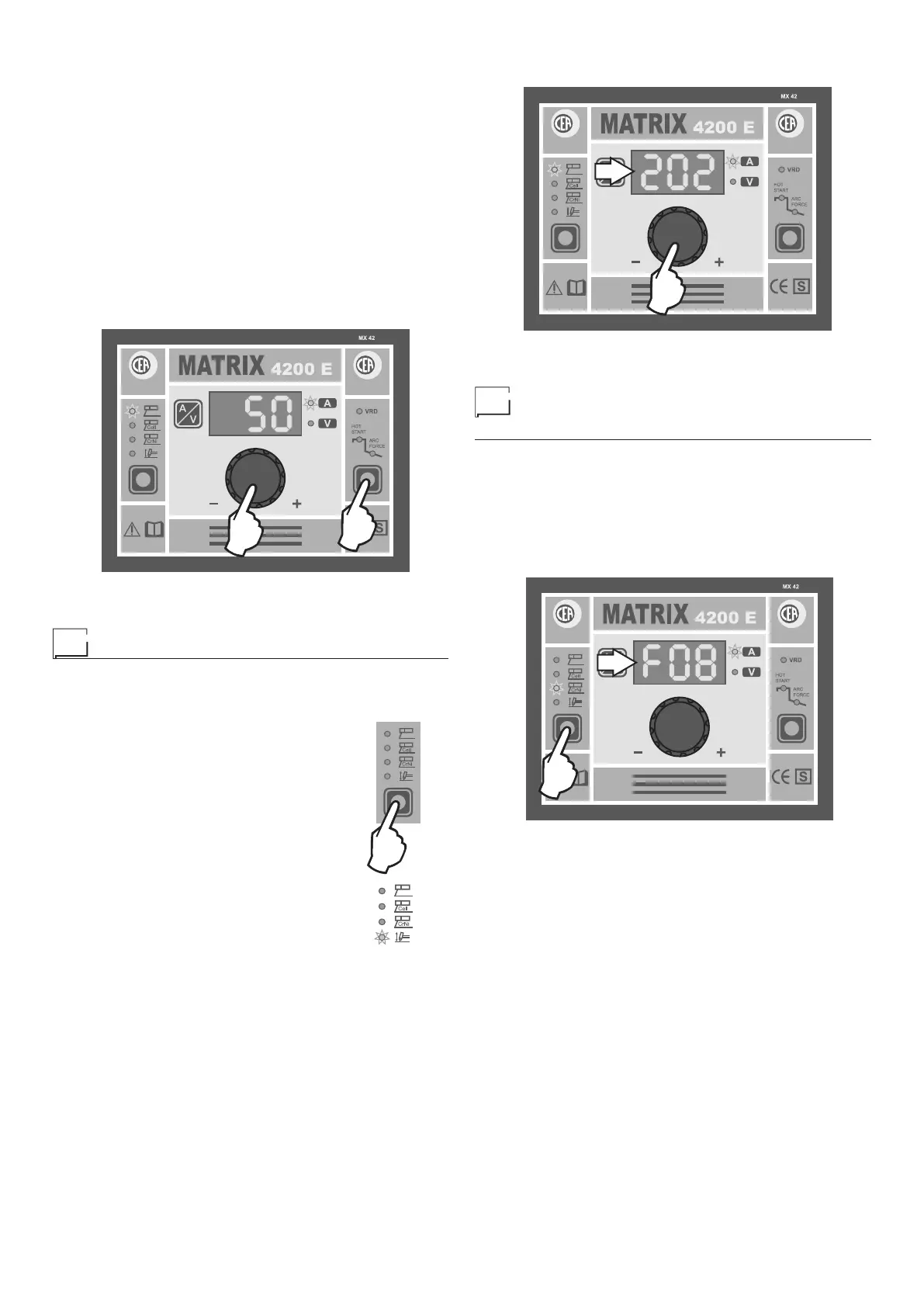

1) Hold down the WELDING PROCESS SELECTION Key for

at least 5 seconds, until the DISPLAY (D) shows a flashing

message that represents the first AUTOMATIC WELDING

POINT (JOB) free and/or available, in which the data can

be saved (example: F08).

T1

D

2000HA90

In order to choose another free JOB simply rotate the EN-

CODER knob and see the other JOBS available. The MX

control panel allows you to save a maximum of 99 AUTO-

MATIC WELDING POINTS (JOBS).

Loading...

Loading...