6

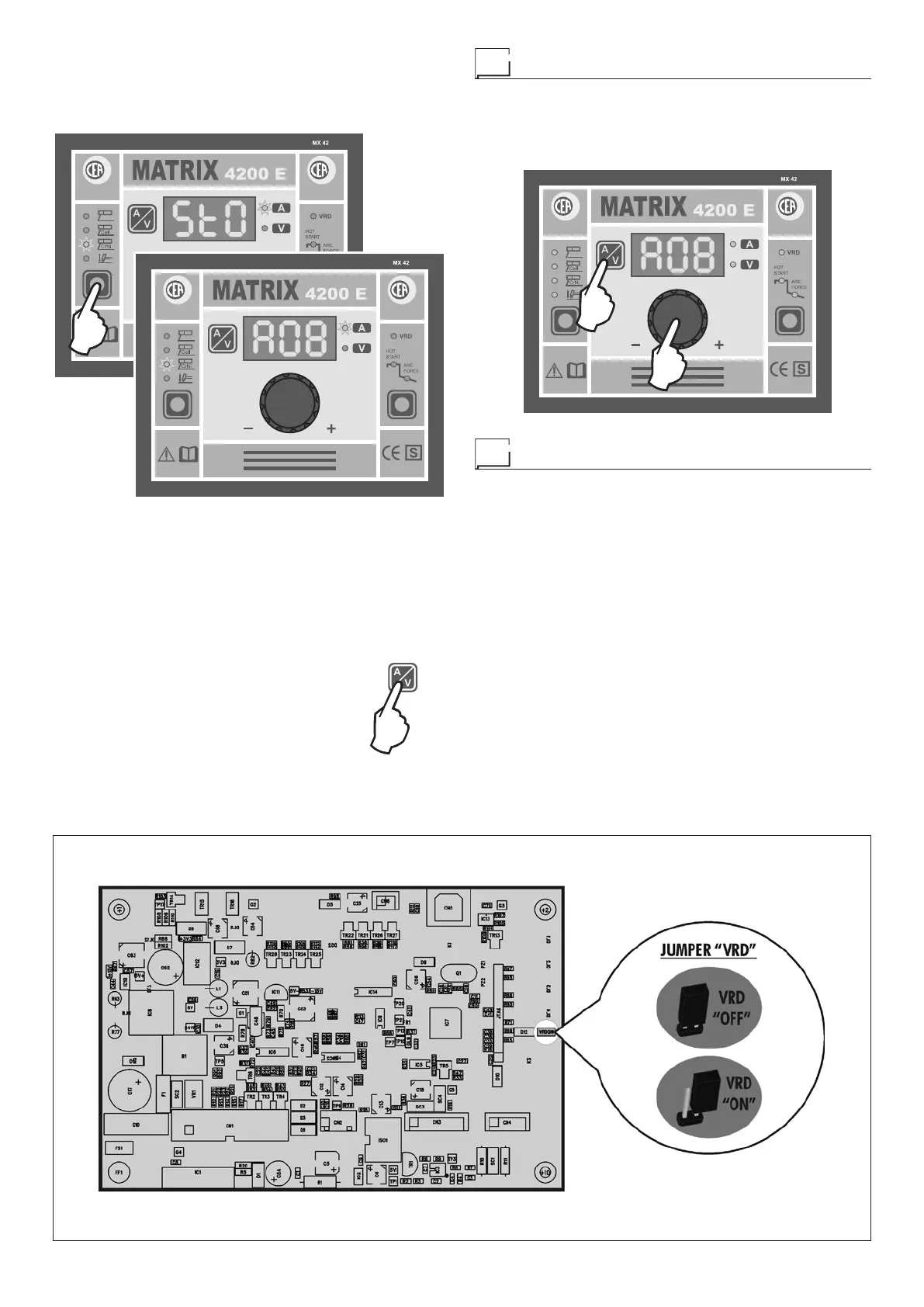

FIG. B

2000HA92

2) To SAVE the JOB simply push the WELDING PROCESS

SELECTION Key (T1) again until the DISPLAY reads

“StO” for about 1 second, which confirms that the JOB

has been saved and then the automatic point chosen (for

example: A08).

T1

2000HA90

Once the saving operation has been completed the control

panel automatically goes to the last JOB saved.

If the user wants to weld in this way they do not need to

adjust any parameter, but if they wish they can view them

by pressing the relevant keys.

NOTE: Creating a JOB implies saving all the special functions

associated with it.

3) To exit the JOB, hold the DISPLAY

SELECTION key down for at least 5

seconds. The welding machine will au

-

tomatically load the values for the JOB

from which it comes.

Recalling automatic welding points

To recall a JOB saved previously:

1) Enter JOB mode by holding the DISPLAY SELECTION key

(T3) down for at least 5 seconds.

2) Rotate the ENCODER knob (E) until you find the JOB re-

quired.

T3

E

2000HA90

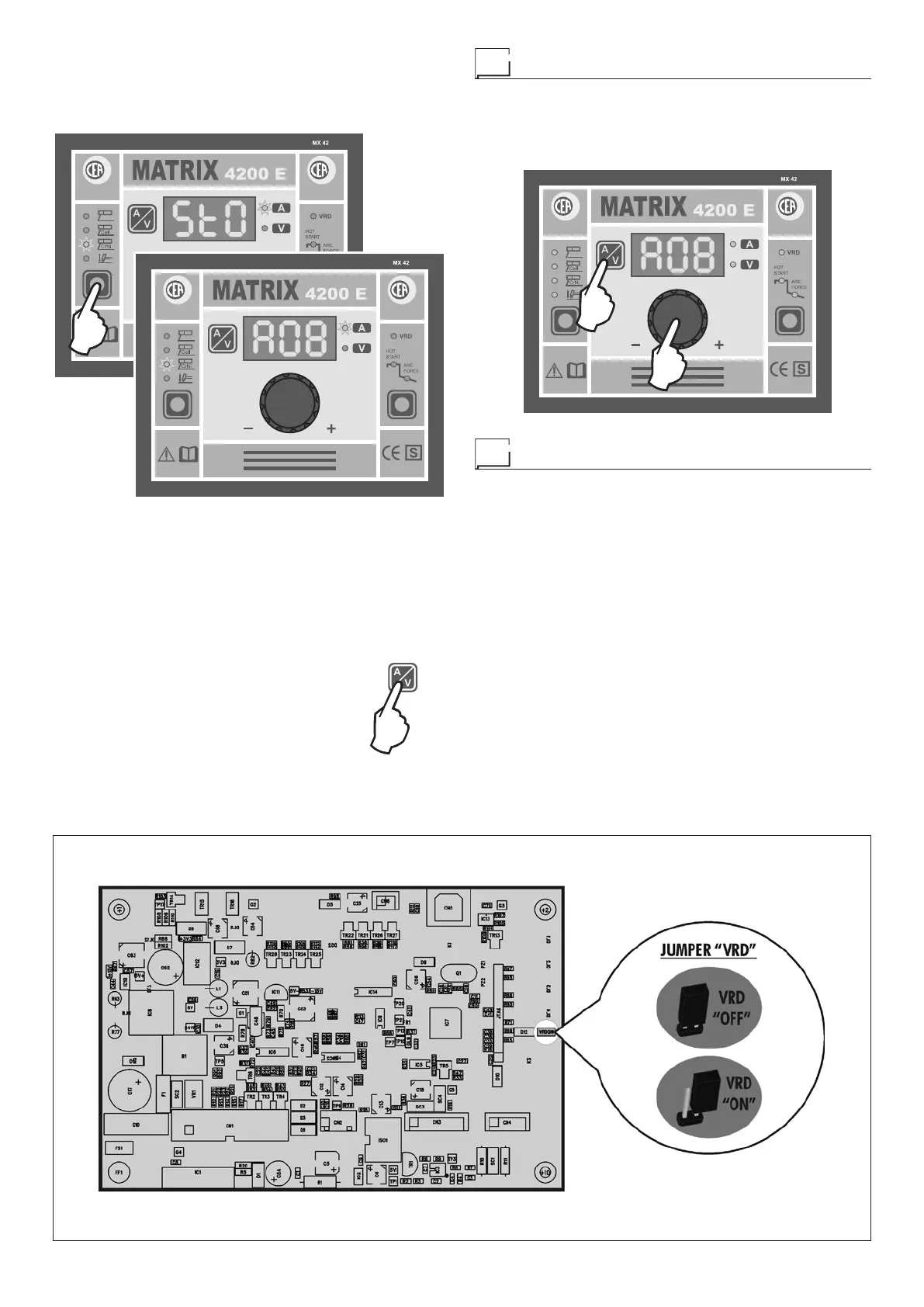

Activating the VRD device

To activate the VRD device, which must be done when the

welding machine is switched off:

1) Use a suitable screwdriver to unscrew the 4 screws that fix

the MX control panel to the welding machine.

2) Remove the “VRD” JUMPER on the DIGITAL INTERFACE

BOARD (Fig. B).

3) Use a suitable screwdriver to tighten the 4 screws that fix

the MX control panel to the welding machine.

4) Start the welding machine by pushing the switch on the

rear panel to position I.

When the MX control panel switches on the VRD LED will

come on and will be GREEN, which means that the VRD func-

tion is on.

To “deactivate” the VRD device and therefore start to weld, fol-

low this simple procedure: First touch the workpiece with the

electrode, then detach it and ignite the arc within a MAX of 0,3

seconds, otherwise if this time is exceeded the VRD device

starts and prevents welding.

Loading...

Loading...