8

Error and protection conditions

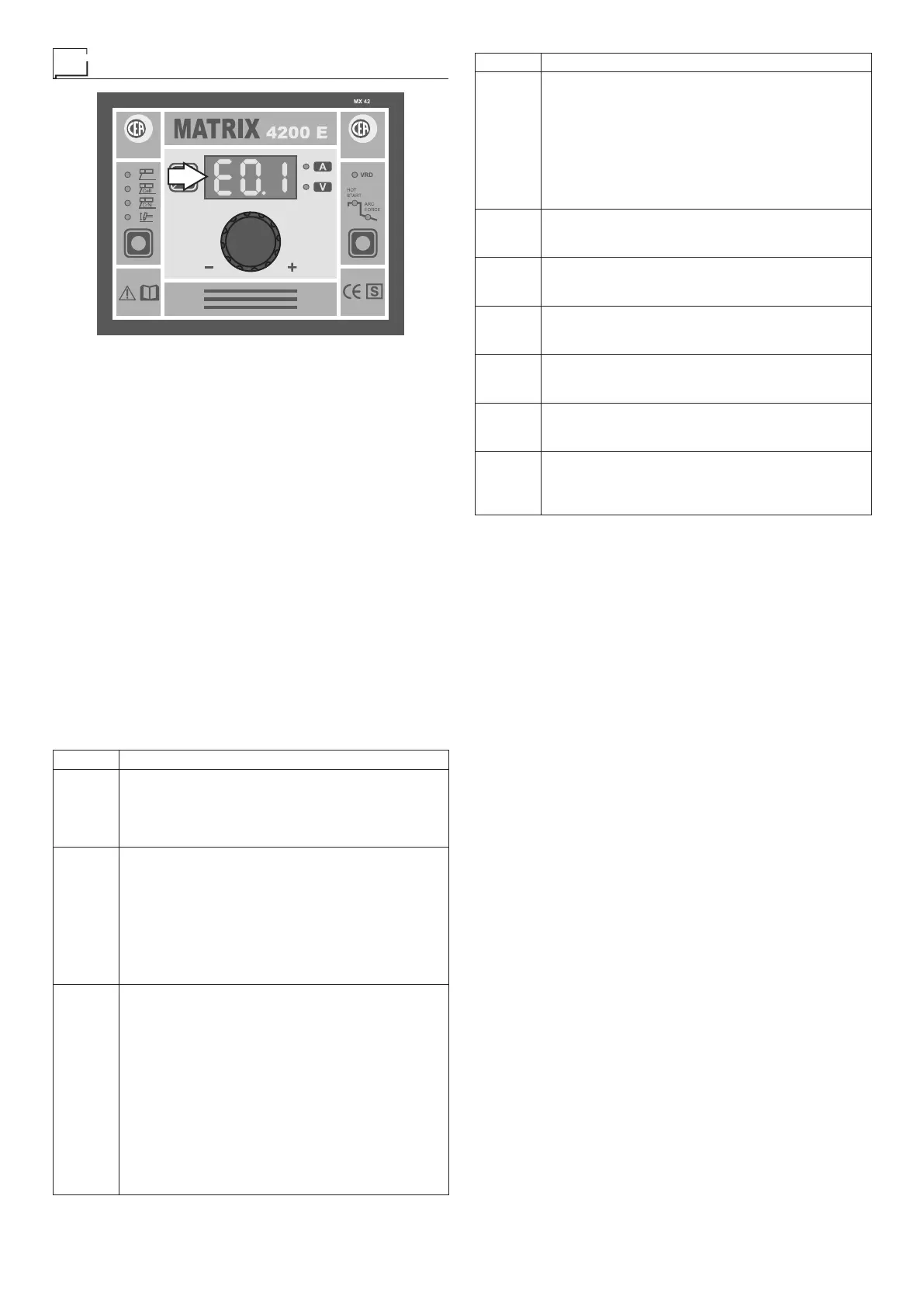

D

The equipment is protected against problems and if any arise

the DISPLAY shows fixed or flashing (error code) messages

(depending on the type of error) that serve to inform the oper-

ator that a fault has occurred in the equipment (see table 1).

The table provides a summary of all the error conditions that

may arise on the equipment and, if possible, what the opera-

tor must do to attempt to resolve the problem.

The table contains 2 types of errors:

•

Errors reset automatically: once the alarm condition has

been resolved the equipment starts working again and the

operator can weld again!

•

Errors NOT reset automatically: To eliminate the alarm

states and reinstate correct functioning of the machine, the

equipment must be switched off.

When it is switched on again, the machine will be working

again and the operator can weld again!

PLEASE NOTE: If when it switches on the error condition

recurs, contact the technical assistance immediately.

All of this is necessary to allow our technical assistance de-

partment (which must be contacted each time error mes-

sages appear on the equipment’s operator interface) to

resolve problems more easily, as quickly as possible and

thanks to the user’s reports, also because, in the meantime

the machine will not allow the operator to do their work.

Table 1

Display Diagnosis

E0.1

UNDER & OVER VOLTAGE

Automatic reset error.

If the fault persists look for the cause of the fault

and contact our technical assistance department if

necessary.

E0.2

OVER VOLTAGE

This is activated when the power supply voltage to

the equipment exceeds 480 V.

Automatic reset error.

The welding machine stops automatically and

resets itself automatically when the voltage returns

within the limits again. If the fault persists look for

the cause of the fault and contact our technical

assistance department if necessary.

E0.3

UNDER VOLTAGE

This is activated when the power supply voltage to

the equipment is less than:

• 320 V (MATRIX 2700 E - MATRIX 2800 E -

MATRIX 2800 E-MG - MATRIX 420 E - MATRIX

420 E-MG - MATRIX 4200 E - MATRIX 4200

E-MG)

• 180 V (MATRIX 2700 E SV)

Automatic reset error.

The welding machine stops automatically and

resets itself automatically when the voltage returns

within the limits again. If the fault persists look for

the cause of the fault and contact our technical

assistance department if necessary.

Display Diagnosis

E0.4

PRIMARY OVER CURRENT

This is activated when the primary current goes

beyond dangerous values.

Automatic reset error.

The welding machine stops automatically and

resets itself automatically when the current returns

within the limits again. If the fault persists look for

the cause of the fault and contact our technical

assistance department if necessary.

E0.5

POWER FAIL

NON automatic reset error.

Immediately contact technical assistance dept.

E1.0

CONFIGURATION FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

E1.1

USER FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

E2.0

FILE SYSTEM ERROR

NON automatic reset error.

Immediately contact technical assistance dept.

E4.0

USER SETTINGS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

t°C

THERMAL PROTECTION

The welding stops due to an excessively high

temperature (thermostat activated).

Automatic reset error.

WARNING: Errors E0.1 – E0.2 - E0.3 cannot be picked up on

the MX22 control panel!

WARNING: The MATRIX 2200E welding machine has a

built-in electronic protective device to deal with fluctua-

tions in mains voltage that switches the machine off auto-

matically (voltage exceeding 300 V), without indicating any

type of error or warning message for the operator. Subse-

quently it starts functioning again automatically when the

voltage has dropped to below the value indicated above.

Loading...

Loading...