ENGLISH

27

Installation and control elements

• CEDIMA

®

• Technical Documentation • All rights reserved as per ISO 16016 • Subject to modications due to progressive development •

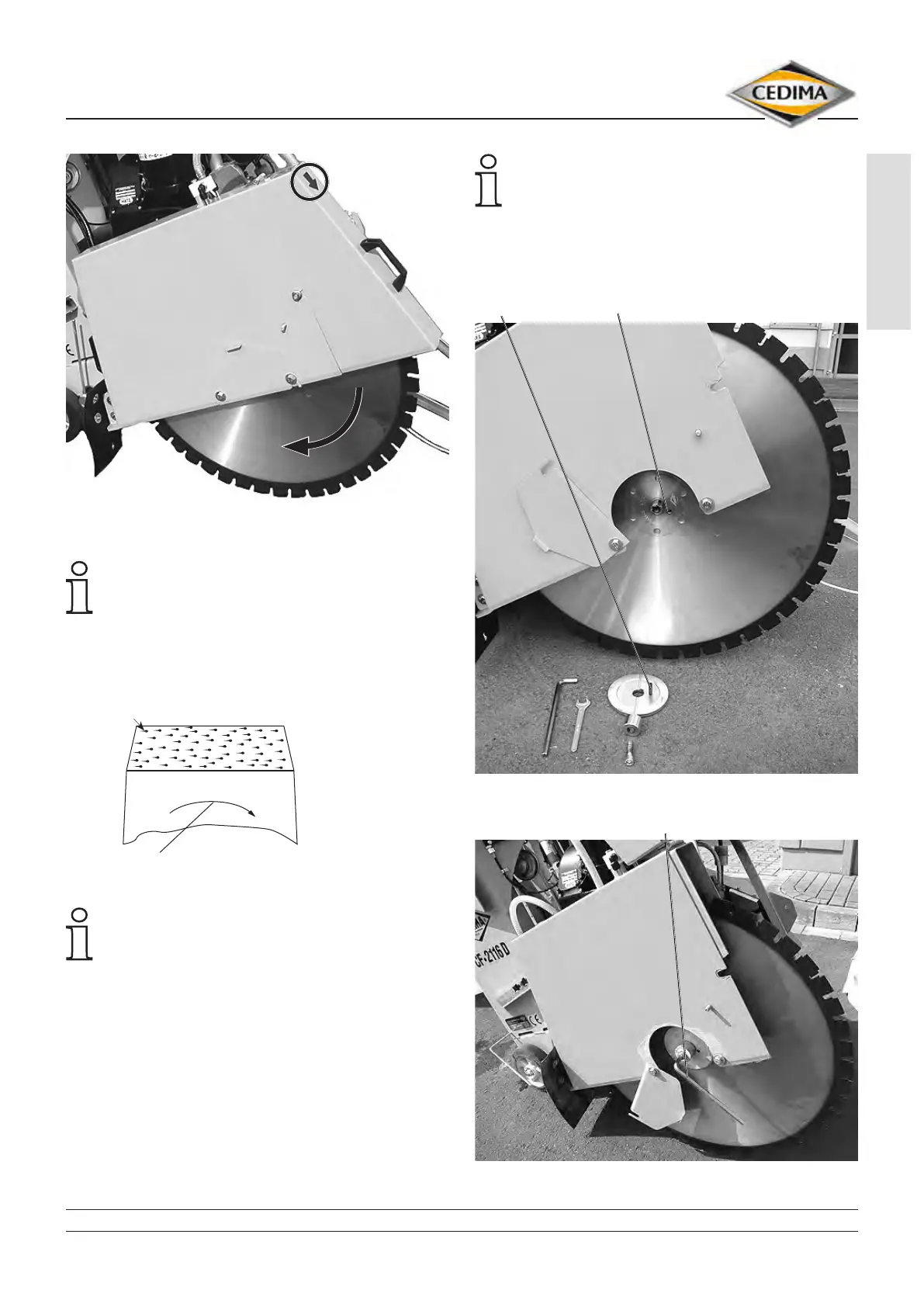

Directional arrows on the CF-2116 D blade guard and the

diamond saw blade Fig. 4.20

Determining the blade’s rotational sense

If the arrow is not visible, the cutting direction of

the saw blade can be determined in the following

way: A “tail” forms behind the diamond during cutting,

so the diamond will always be to the front in relation to

the direction of rotation!

segment

diamond “tail”

direction of rotation

Fig. 4.21

Re-sharpening blunt diamond saw blades

Diamond saw blades are designed to re-sharpen

themselves during cutting operation. They can

become blunt by frequent cutting in heavy steel

armouring or in hard material, which is only slightly

abrasive. Blades can be re-sharpened by cutting in an

abrasive material such as chalky sand stone or asphalt!

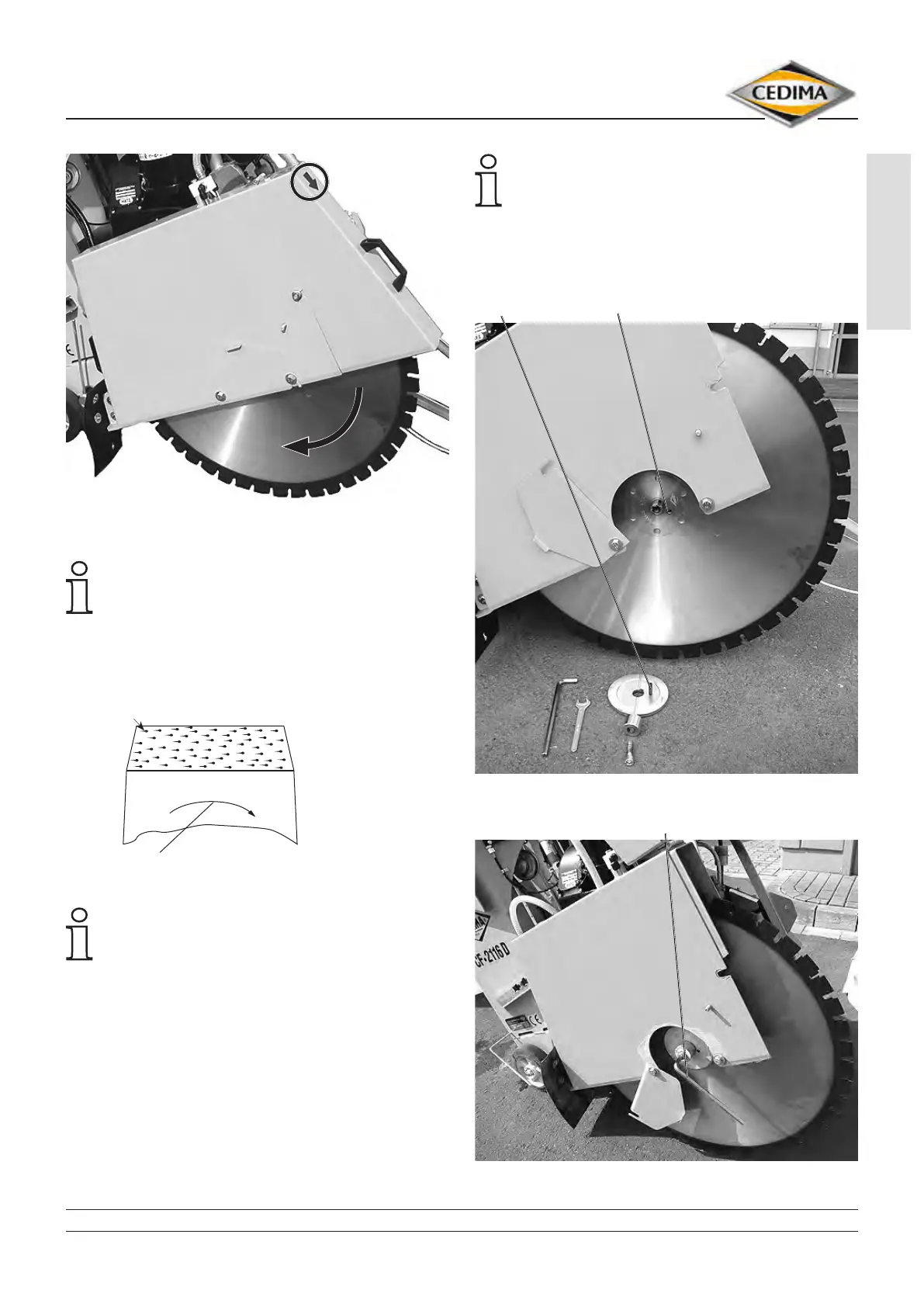

8. Fit the blade clamping ange with the sealing ring

and screw drive pin on to the blade shaft and screw

the blade shaft screw tight (left-hand thread, g. 4.19,

4.22 and 4.23)!

Make sure that the drive pin extends through the

bore hole into the blade mounting ange.

9. Put the clamping ange onto the cutting shaft and

re-screw the cutting shaft screw (left-hand thread, g.

4.23).

CF-2116 D standard, mounted saw blade Fig. 4.22

drive pin bore holes for drive pin (ange, saw blade)

CF-2116 D standard, tensioning the saw blade Fig. 4.23

Allen key

Loading...

Loading...