ENGLISH

40

Maintenance and care

• CEDIMA

®

• Technical Documentation • All rights reserved as per ISO 16016 • Subject to modications due to progressive development •

6.6 Maintenance work on the CF-2116 D

ATTENTION!

Observe the safety instructions of this

operating manual!

ATTENTION!

Use genuine parts!

Only be using genuine parts of spare parts

approved by CEDIMA

®

the operational safety of the

CF-2116 D can be guaranteed.

6.6.1 Measures concerning health,

accident prevention and

environment protection

• Avoid any lengthy contact with oil, carefully clean the

skin from any clinging oils!

• Especially avoid contact with liquid uids at a tem-

perature of above 60°!

• Oil contact with the eyes needs an immediate, careful

and thorough rinsing with drinking water and eventu-

ally a visit to a doctor!

• Take care when using pressurised uids! There is a

risk of injury through escaping hydraulic oil (under

pressure). Any sort of manipulation on the hydraulic

system should be avoided!

• Oil leakage should be removed or treated straight

away with a binding agent!

• Oil should not be allowed to seep in to the ground or

in to open drains!

• Used oils should be collected and stored properly,

until collected by a qualied rm, competent in han-

dling used oils!

Pay attention and follow the valid laws and regulations

concerning handling and disposal of oils in the

respective country where operations are carried out!

Information can be obtained from the appropriate ofce

in question.

6.6.2 Tensioning the cutting shaft V-belts

For tensioning the four cutting shaft V-belts proceed as

follows:

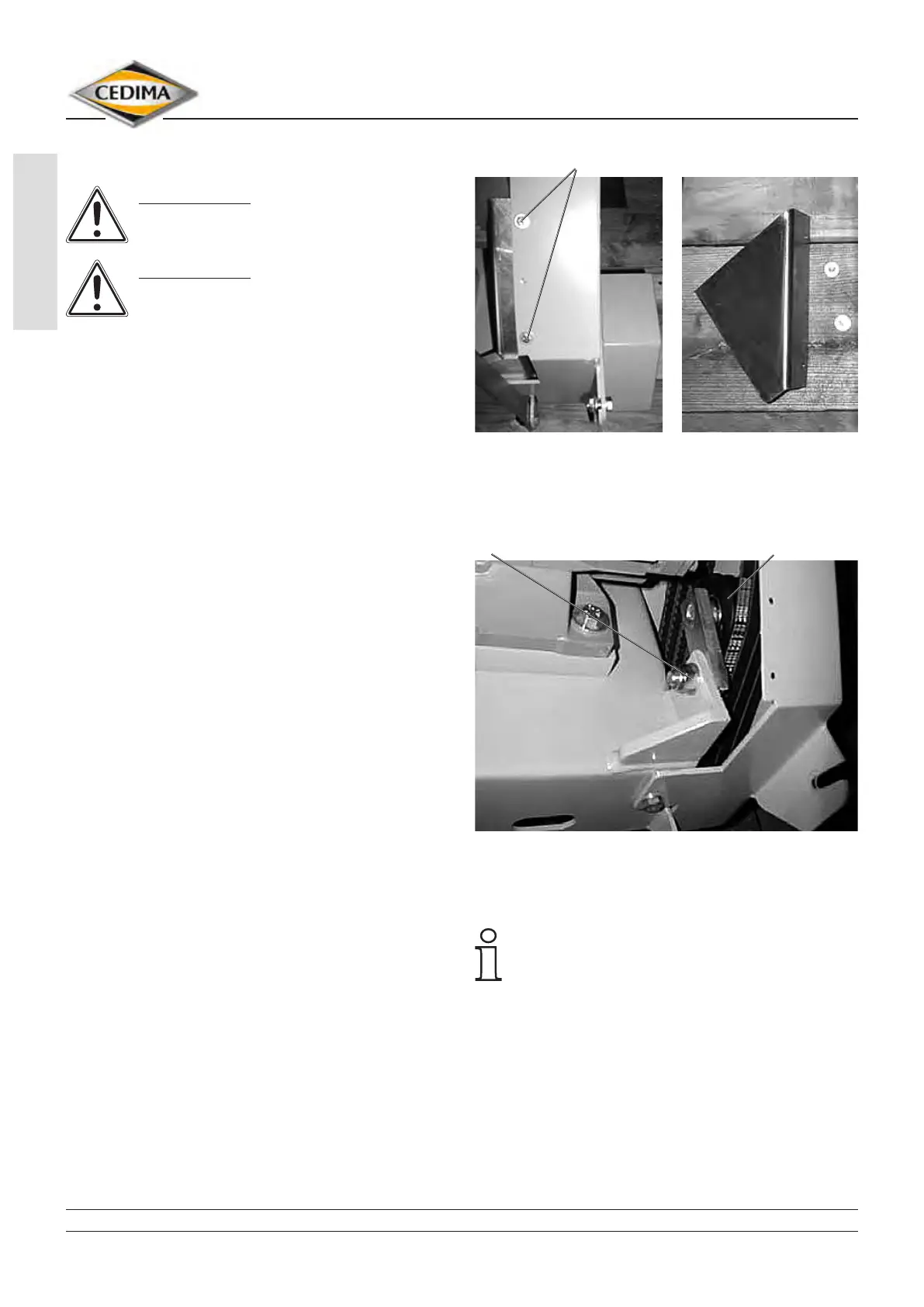

1. Dismount the cover sheet over the V-belt tensioning

device in front of the V-belt cover (g. 4.4, 6.1 and

6.2). For this, loosen and remove the two screws

(size 10 mm) with washers.

Cover sheet at the fore of V-belt cover Fig. 6.1

screws with washers

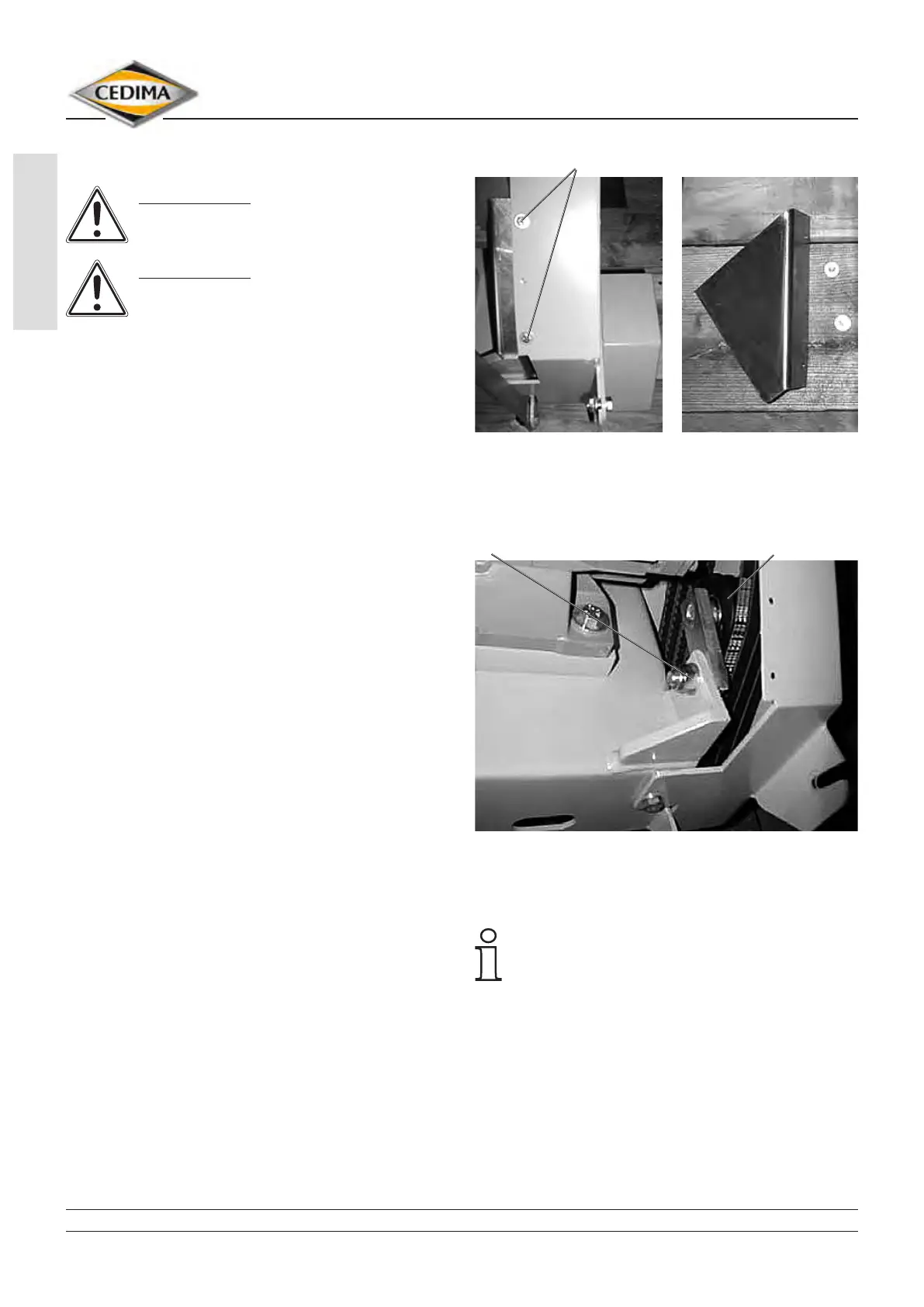

2. Loosen the nut at the V-belt tensioning device (g.

6.2).

Dismounted cover sheet at the fore of V-belt cover Fig. 6.2

nut at V-belt tensioning device V-belt tensioning roll

3. Pull the V-belt tensioning roll upwards and/or push it

up against the V-belts (g. 6.2).

Place a suitable open-ended spanner (rear) on

the V-belt tensioning arm.

Press the V-belt tensioning roll with the V-belt

tensioning arm against the cutting shaft V-belts.

Do not damage the V-belts with a pointed or sharp-

edged tool!

4. Hold the V-belt tensioning arm (tensioning roll) and

re-tighten the nut at the V-belt tensioning device (g.

6.2).

Loading...

Loading...