ENGLISH

44

Maintenance and care

• CEDIMA

®

• Technical Documentation • All rights reserved as per ISO 16016 • Subject to modications due to progressive development •

The hydrostatic gear is equipped with an expansion

tank (on the gear, g. 6.9 and 6.10) and factory-made

lled with corresponding hydraulic oil (refer to section

6.7). There is a cold/warm mark at the expansion tank.

In cold condition the oil level should not exceed the

cold mark (lower mark).

The cooling ns of the gear box are to be kept clean to

avoid overheating. Oil overheating might lead to gear

damages. Overheated oil has lost its greasing proper-

ties and has to be replaced. It can be recognised by its

black colour.

Change the CF-2116 D’s feed gear oil as follows:

1. Warm up (operate the machine) the hydrostatic feed

gear oil in order to drain the used oil components

tending to sedimentation as well.

2. Remove the water tank.

3. Place a suitable drip cup for approx. 0.65 litres hot

hydraulic oil beneath the hydrostatic feed gear.

DANGER!

Danger of injury due to hot hydraulic oil!

Wear appropriate gloves and use suitable

tools.

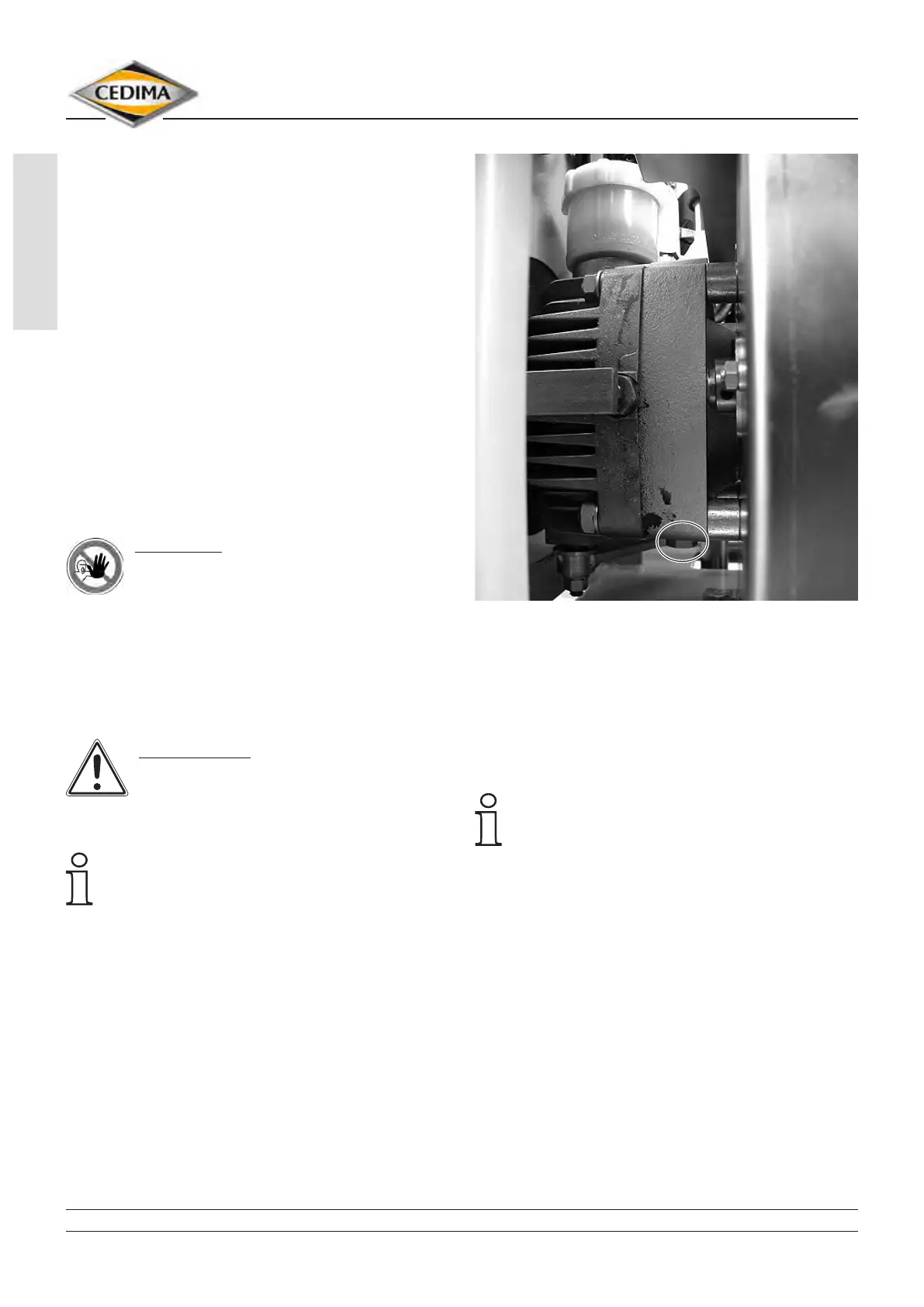

4. Loosen and remove the oil drain screw beneath the

hydrostatic feed gear (g. 6.10) and collect the oil.

5. Loosen and remove the ventilation/lling screw at

the hydrostatic feed gear (right beside the expansion

tank, g. 6.9).

ATTENTION!

Observe the safety instructions in chapter

3 and section 6.6.1. Handle the hydraulic

oil according to the supplier’s instructions.

Collect and discharge the used and leaked

hydraulic uid environment-friendly, according to

the local laws.

Provide information from the competent authority!

CF-2116 D, oil drain screw beneath the hydrostatic feed gear

Fig. 6.10

6. Clean the area of the oil drain screw and tighten the

screw together with a new seal ring.

7. Clean the bleeder screw’s position and brim-fully ll

in new hydraulic oil (section 6.7). If necessary, use a

funnel. Pay attention to utmost cleanliness. Neither

dirt nor water might penetrate the oil circuit.

Provide cleanliness when changing the

hydraulic oil!

Dirt is the greatest enemy of hydraulic

installations. Close all opened ller plugs as soon as

possible.

Provided that changing the hydraulic oil is effected in

time the hydrostatic feed gear has been designed for a

long lifetime. Polluted hydraulic oil will short the gear’s

lifetime considerably.

8. Hand-screw the bleeder screw together with a new

seal ring.

9. Fill the oil expansion tank with new hydraulic oil up to

2 cm below the cold mark. Close the lid.

10. Start the joint cutter’s motor, engage the feed gear

and drive the joint cutter for a short while with the

hydrostatic feed gear.

11. Disengage the feed gear and shut off the joint cut-

ter.

Loading...

Loading...