ENGLISH

45

Maintenance and care

• CEDIMA

®

• Technical Documentation • All rights reserved as per ISO 16016 • Subject to modications due to progressive development •

12. Check the oil level of the hydrostatic feed gear

again and, if necessary, ll up oil.

13. Repeat as described in 7. and 9. to 12. until the

hydrostatic feed gear is sufciently lled.

14. Tighten the bleeder/lling screw.

15. Put the water tank back on the CF-2116 D’s water

tank console.

6.6.7 Checking the lling of the hydraulic

cutting shaft lifting/relling

DANGER!

Maintenance works must only be carried

out when the joint cutter has been shut

down.

Check the lling level and change the oil for the cutting

shaft lifting as per maintenance table 6.5. The electro-

hydraulic compact unit for lifting the cutting shaft/saw

blade is built in the front left part of the superstructure

box and accessible after removal of the water tank (g.

6.11).

DANGER!

Danger of injury due to hot hydraulic oil!

Wear appropriate gloves and use suitable

tools.

ATTENTION!

Observe the safety instruction in chapter

3 and section 6.6.1.

Handle the hydraulic oil as per supplier’s instructions.

Electro-hydraulic compact unit in CF-2116 D (water tank

removed) Fig. 6.11

Control/ller plug

Electric motor

Assure utmost cleanliness of the hydraulic

uid. Neither dirt nor water might penetrate the

hydraulic circuit.

Dirt is the greatest enemy of hydraulic installations.

Close all opened ller plugs as soon as possible.

Provided that changing the hydraulic oil is effected in

time the compact hydraulic unit has been designed

for a long lifetime. Polluted hydraulic oil will short the

gear’s lifetime considerably.

Check and ll up the oil for the cutting shaft lifting as

follows:

1. Dismount the saw blade and lower the cutting shaft

completely (sections 4.3.1 and 4.5.3) to achieve that

the compact hydraulic unit is lled with oil up to the

maximum mark.

2. Remove the water tank.

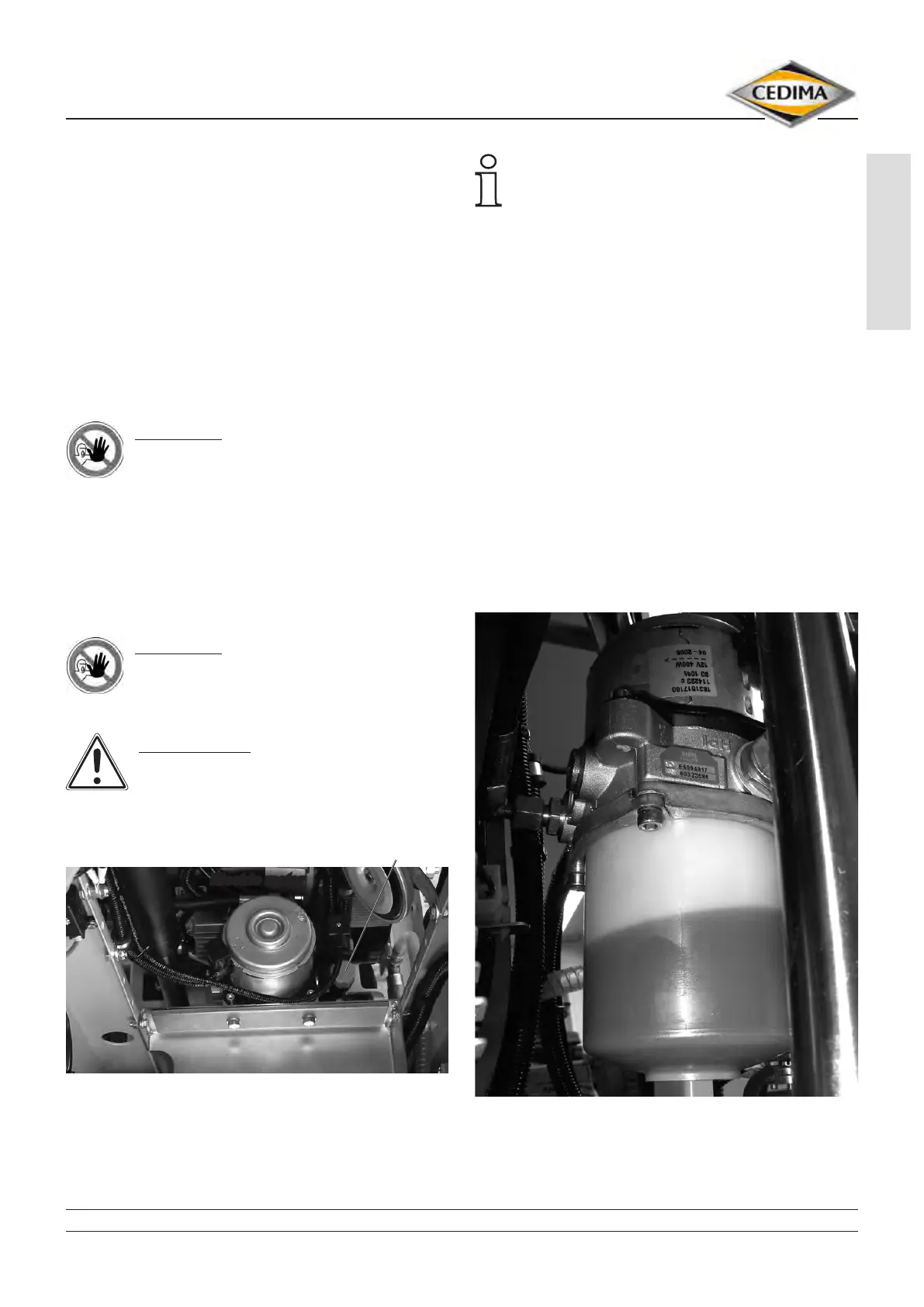

The compact hydraulic unit is equipped with a transpar-

ent oil collecting tank (under the electric motor, g. 6.12

and 6.13) and factory-made lled with corresponding

hydraulic oil (refer to section 6.7). The transparent col-

lecting tank allows already from outside to recognize

the hydraulic oil level.

Hydraulic oil level in teh transparent collecting tank of the electro-

hydraulic compact unit in CF-2116 D Fig. 6.12

Loading...

Loading...