Chemtrac Systems, Inc.

Page 48

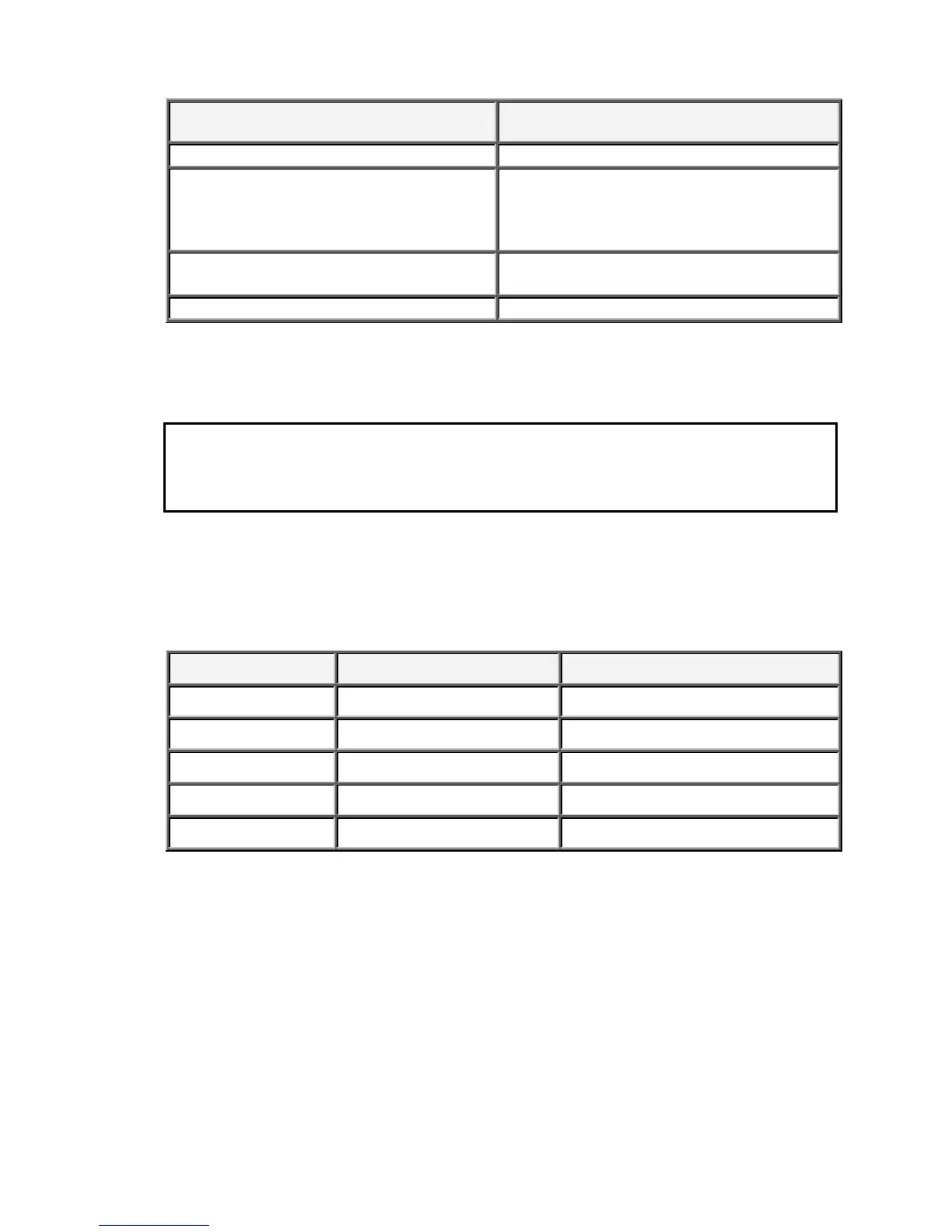

TYPE OF CONTAMINATION CLEANING PROCEDURE

Mineral scale from alum/lime addition Comet or other Abrasive Cleaner

Deposits caused by raw water

iron/manganese, or where ferric salts or

potassium permanganate is used for

treatment.

ROVER (available from Hach Chemical)

1 spoonful per pint tap water

Organics from raw water or where

polymers are used.

Comet or other Abrasive Cleaner

Oil/Grease Comet or other Abrasive Cleaner

A “soak and brush” method is recommended for any contaminant. Soak only long

enough to dissolve/remove the material. Probe surfaces should be thoroughly washed

with clean water to remove any residual cleaning compound.

CAUTIONS

R Do not soak entire probe cartridge, only soak inside the bore. Acid concentration

shall not exceed 15% concentration.

6.3 REPLACEMENT PARTS

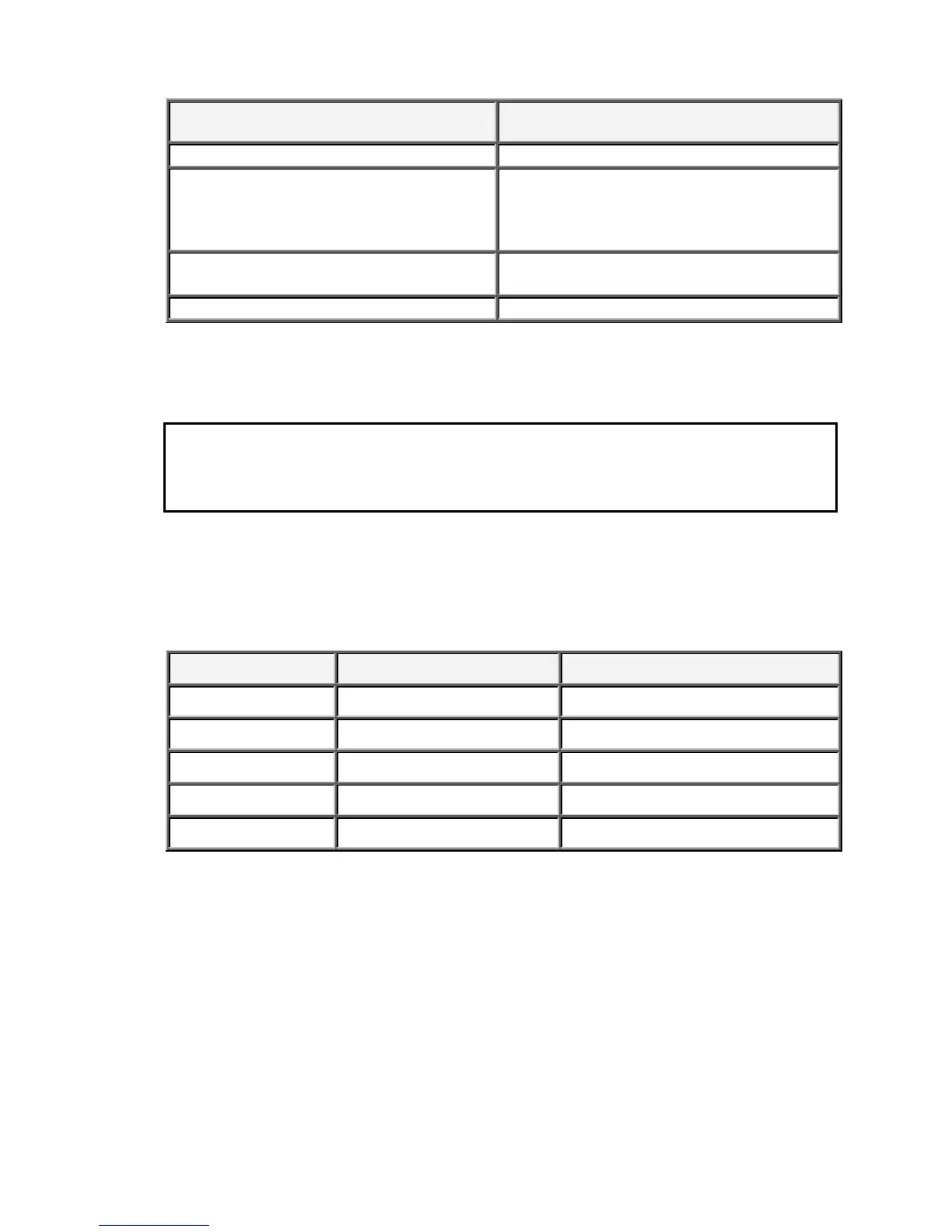

Figure 12 AND 13 illustrates Dura-Trac and Dura-Trac II sensor parts identification with

part numbers. Table below lists recommended replacement parts.

Part Number Description Replacement Interval

1701 Delrin Piston 1 to 2 years

8601 Probe Cartridge 1 to 3 years

1301 110VAC Drive Motor 3 to 5 years

5017 Viton Diaphragm 3 to 5 years

8702 Probe Washer If Lost

Loading...

Loading...