Chemtrac Systems, Inc.

Page 45

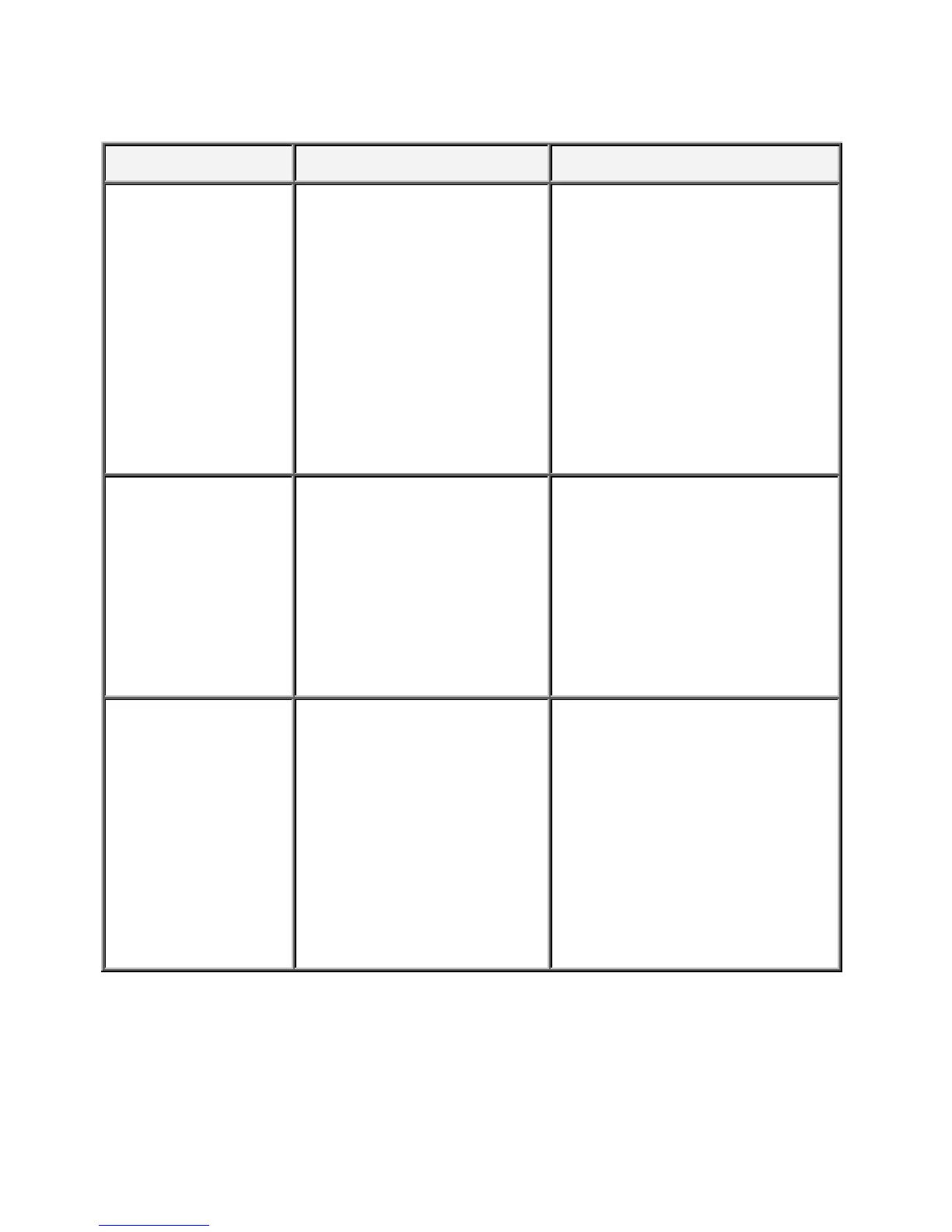

SECTION 5.0 TROUBLESHOOTING GUIDES

PROBLEMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

1. Display fluctuates

rapidly and widely

on treated sample.

A. Incomplete dispersion or

mixing of coagulant(s) in

raw water at point of

sampling.

B. Chemical feeders erratic or

partially plugged.

C. Raw water flow-turbidity

fluctuating.

D. GAIN setting too sensitive.

E. Cell bottom plug loose or

O-ring missing.

A. Check stability of readings on

raw or finished water. If stable,

incomplete mixing is the

problem. Move sampling point

further downstream, or resolve

mixing problems.

B. Fix feeders.

C. Check R/W flow controls/charts,

and turbidity.

D. Decrease GAIN setting.

E. Tighten plug. Check O-ring

(See Cleaning Procedures).

2. Display does not

change with

change in

coagulant dosage.

A. GAIN setting too low.

B. Wrong sample point or

insufficient mixing..

C. Sample cell dirty.

D. Excessive “lag time”

between coagulant

injection point and sensor

sample cell.

A. Increase GAIN setting.

B. Select correct sample point.

C. Clean cell (see Cleaning

Procedures).

D. Move sampling point closer to

coagulant feed point and/or

decrease sample TRANSPORT

time (See Selecting Proper

Sample Point).

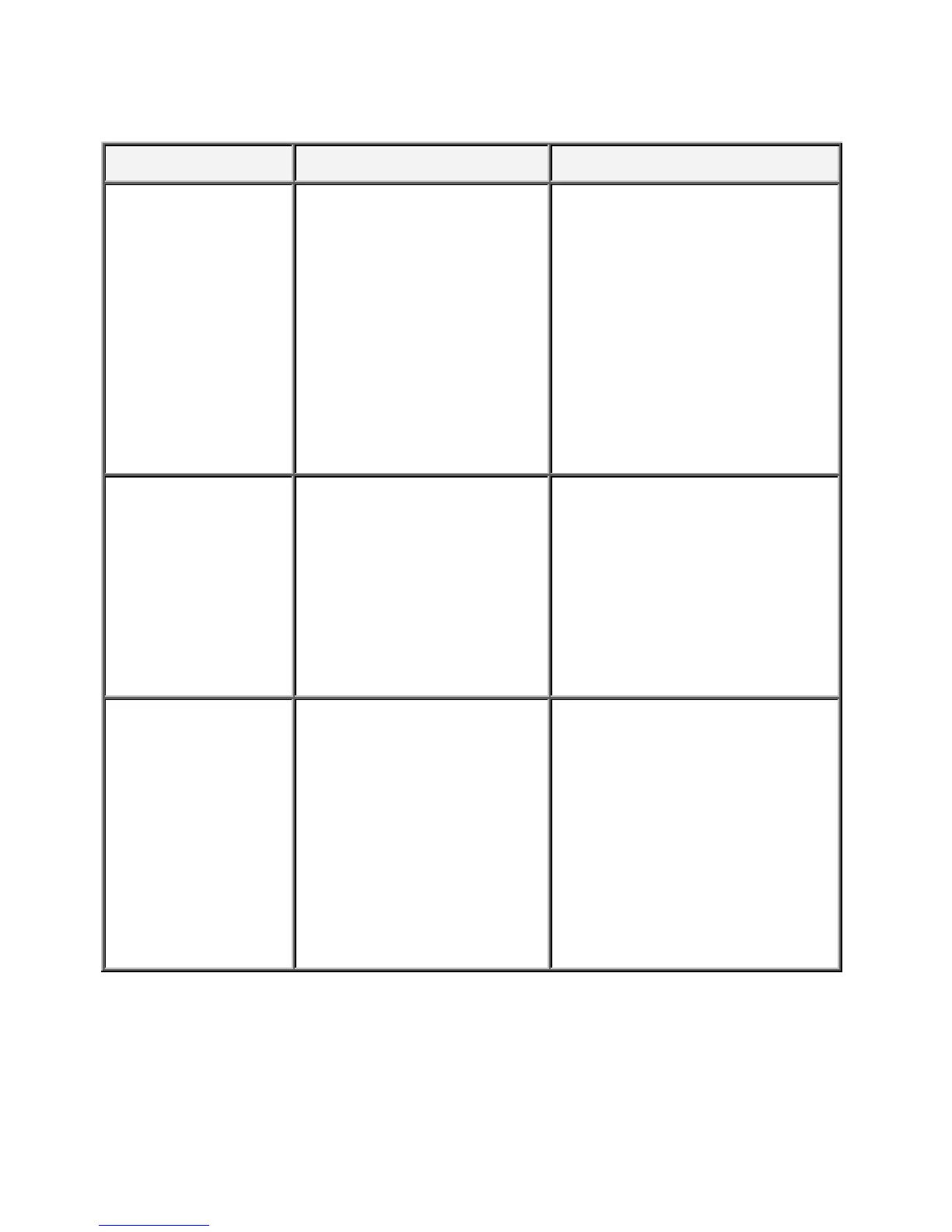

3. Display indicates

0.00, or closely

thereto, and does

not change with

change in

coagulant dosage.

A. No water sample to sensor.

B. Motor not turning.

C. Dirty or inoperative probe.

D. Opt switch misaligned.

E. Opt switch inoperative.

F. Sensor output connections

incorrect.

G. Circuit card component

faulty.

A. Establish proper sample flow.

B. Turn on motor.

C. Clean or replace probe.

D. Adjust opt switch position for

maximum meter reading on

water sample and tighten

securely in place.

E. Replace opt switch.

F. Check wiring.

G. Replace circuit card.

Loading...

Loading...