Chemtrac Systems, Inc.

Page 7

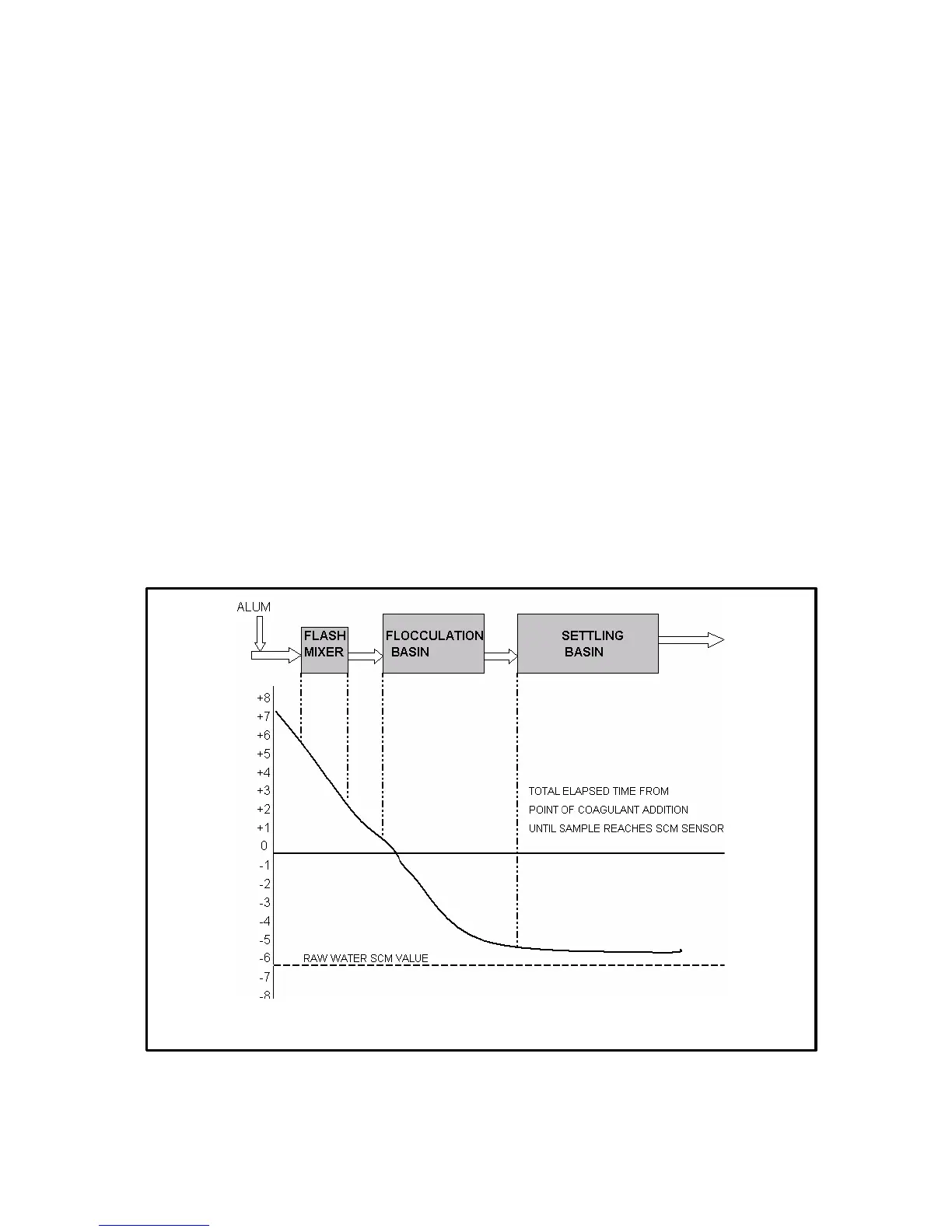

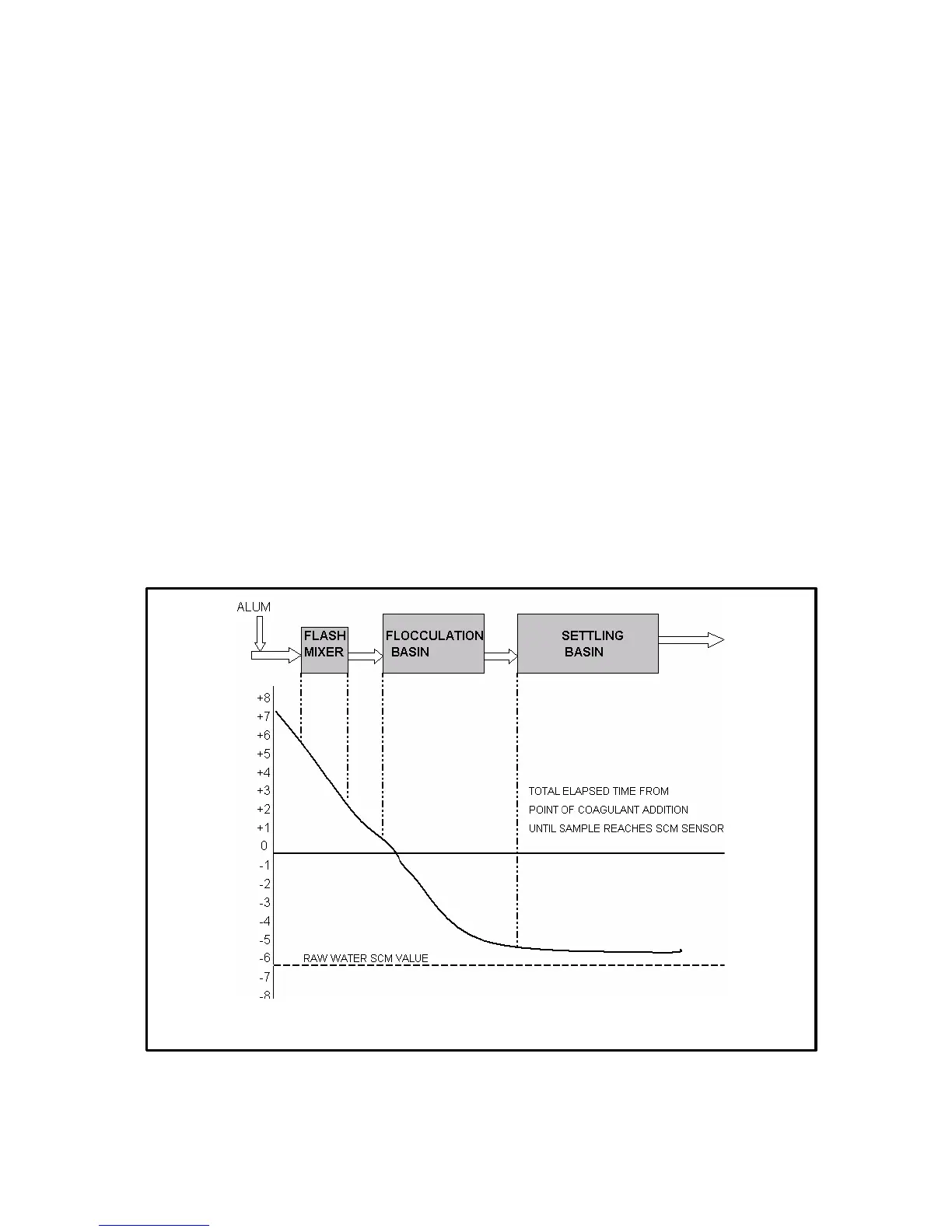

degree, temperature. Untreated raw water has a net negative charge. Cationic

coagulant charges, (alum, polymer, etc.) can produce a net positive streaming current

early in the system. As shown on the graph, this current becomes less positive as

negative charges react with the coagulant. At the settling basin outlet, the streaming

current value can return to nearly the same as raw water. If raw water flow or sample

flow rate is increased, the total time for the sample to travel from point of coagulation

injection to the cell is decreased. This may cause a change in monitor reading (in the

positive direction), even though the coagulant dosage (PPM) remains constant.

Conversely, if raw water or sample flow rate is decreased, streaming current readings

may go more negative. Plants that have a shifting set point caused by wide swings in

raw water flows can minimize this effect by moving the sample point further

downstream, lengthening sample line, or adding a detention pot. It is important to

maintain the sample flow at +/- 10% of the rate initially set.

Based upon the above discussion, the proper sample point for a specific plant depends

upon the following conditions:

1. Point or points of coagulant feed.

2. Mixing efficiency of raw water and coagulant.

3. Magnitude of raw water flow swings.

4. Type and quantity of coagulants used.

FIGURE 1. Streaming Current Profile

Loading...

Loading...