Chemtrac Systems, Inc.

Page 33

NOTES

R Sample Isolation and Chemical Wash is only available with the optional SMM.

The Dura-Trac with flush option does not include the sample isolation or chemical

pump feature; however, there will still be a delay between sensor flush and rinse.

3.4 SYSTEM OPERATION

After sample flow is established and power has been applied to the sensor and

streaming current monitor, allow 10-15 minutes or longer for the reading to stabilize.

Stable conditions differ from plant to plant. The reading may fluctuate 10 to 20 units,

even under stable conditions due to the chemical not being thoroughly mixed. If

readings fluctuate widely, refer to Troubleshooting Guide. The monitor’s reading may

be negative, zero, or positive. The monitor is simply indicating the streaming current

value of the sample. In most applications, the reading will be slightly negative (anionic).

After the reading has had ample time to stabilize, adjust the chemical dosage in normal

increments to test the response of the monitor. For model SCC3500XRD, enter the

Control menu to manually adjust chemical feed. For each dosage change, the reading

should respond by changing 20 to 50 SCV units. If the response is less than 20 units,

increase the gain. Likewise, if the response is greater than 50 units, it is recommended

to decrease the gain (especially if the monitor is to be used for automatic chemical feed

control).

Next, a test should be performed to determine the Raw SCV reading. This will help

determine the LO SCV Alarm setting and give a better understanding of instrument

response. To determine the Raw SCV reading, shut off sample flow to the sensor and

turn the outlet fitting up. Pour a sample of raw untreated water into the sensor and allow

the reading to stabilize and then record the reading. This reading should serve as an

absolute alarm value, which if measured by the monitor will indicate a loss of chemical

feed. It is recommended to set the Lo SCV Alarm value (see Alarm setup menu)

between the Raw SCV measurement and the setpoint value. Further testing will help to

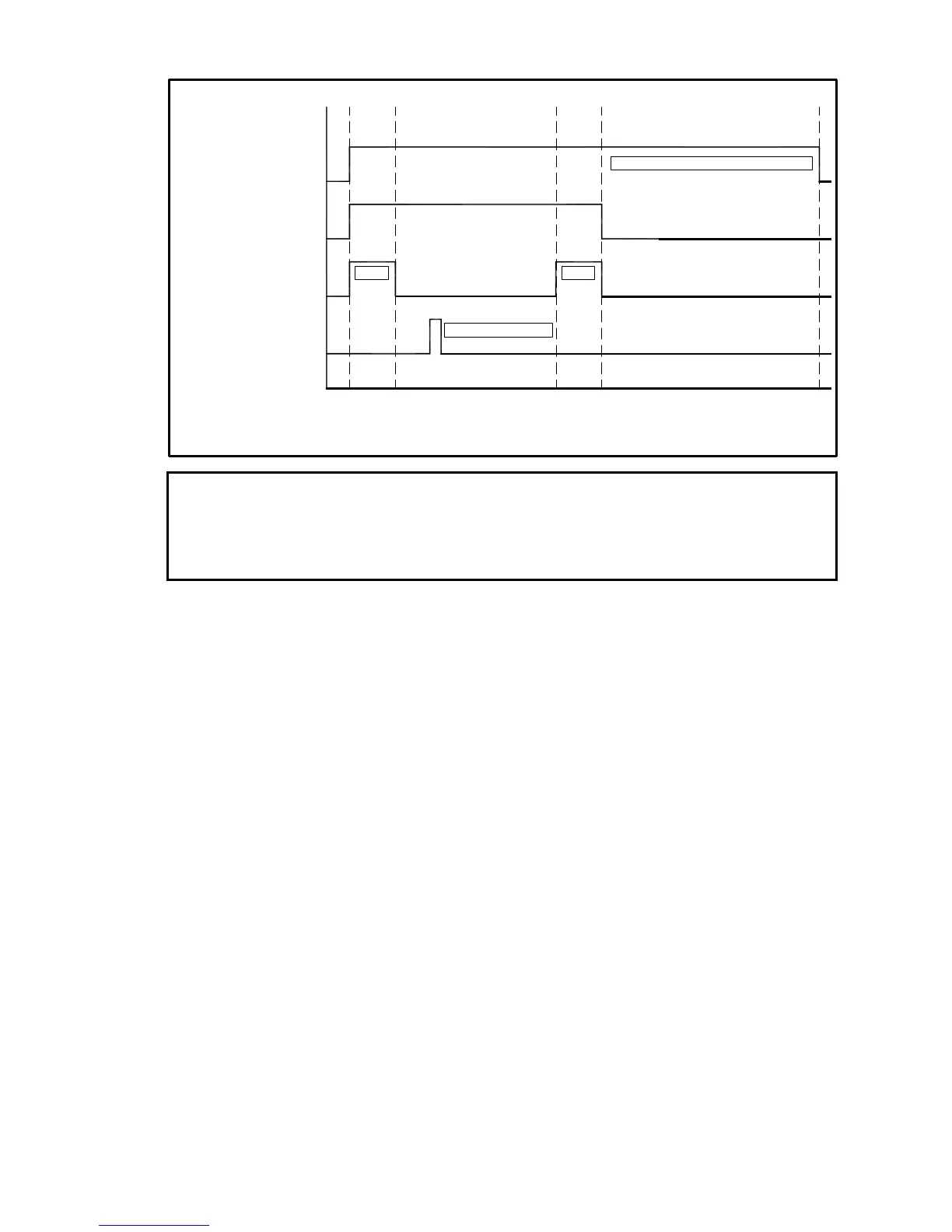

ON

OFF

PUMP OUTPUT HOLD

SAMPLE ISOLATION

CHEMICAL PUMP

SENSOR FLUSH

OFF

ON

OFF

ON

OFF

ON

HOLD PERIOD

WASH PERIOD

TIME (SECONDS)

AND RINSE

RINSEFLUSH

FIGURE 11. Automatic Flush Timing Diagram

Loading...

Loading...