CT-S4000 Service Manual

16

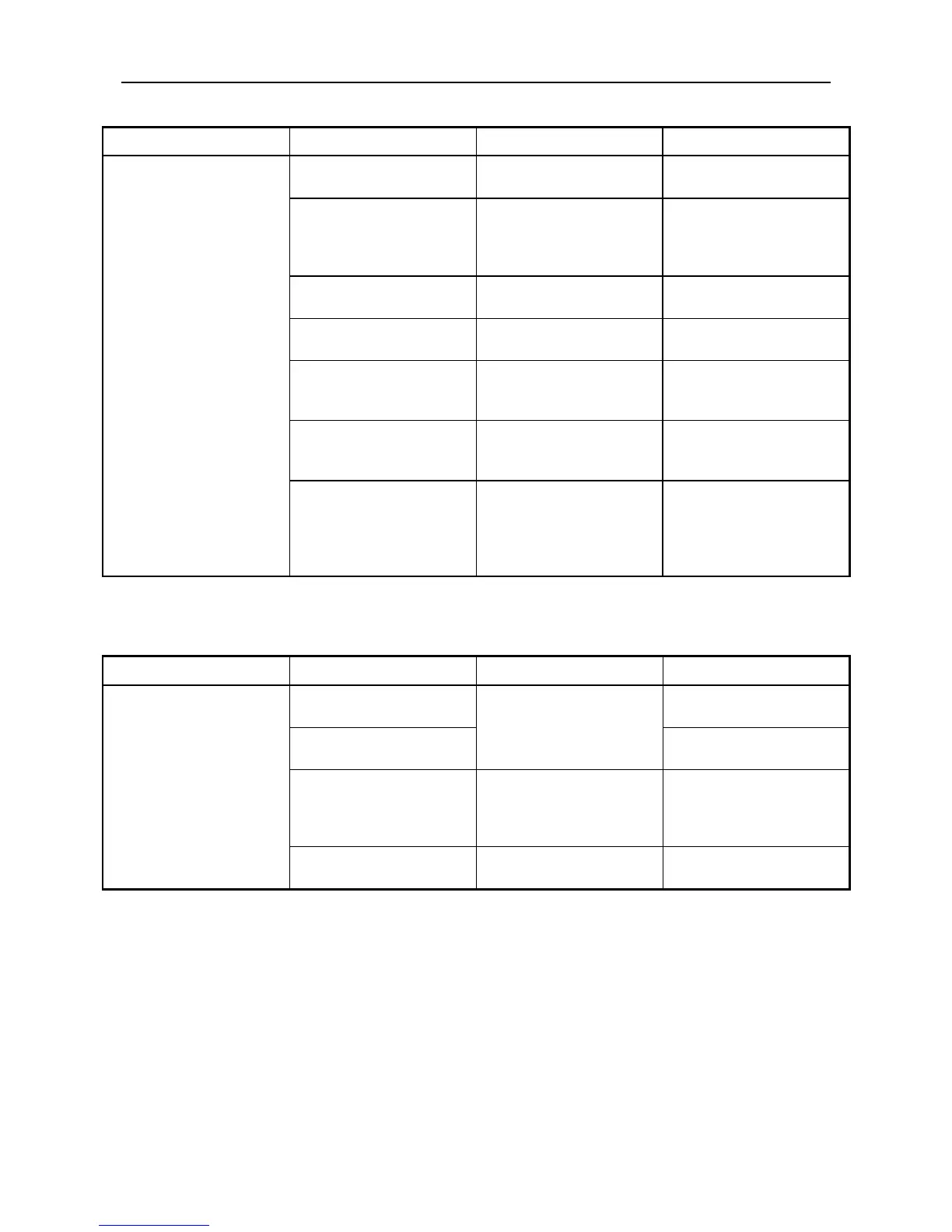

• Paper feed failure

Phenomenon Cause Check Method Remedy

Faulty connection of the

motor connector

Check the connector

connection.

Connect the connector

correctly.

Failed motor’s main unit

Use tester or

oscilloscope or other

instrument to measure

supply voltage.

If the supply voltage is

normal, replace the

motor.

Low output voltage

Check the supply voltage

with tester or others.

Use within specified

voltage range.

Faulty control PCB assy —

Replace the control PCB

assy.

Faulty mounting of the

platen roller

Check mounting

condition of the platen

roller.

Mount the platen roller

properly.

Paper feed failure

Check that no paper is

jammed, torn or caught in

the paper path.

Remove unnecessary

paper and set correctly.

Paper is not fed or

jammed.

Foreign substance in the

gear or broken gear

Remove the gear holder

and check for any foreign

substance caught in the

gears or any breakage of

the gears.

Eliminate the foreign

substance. If the gear is

broken, replace it with

new one.

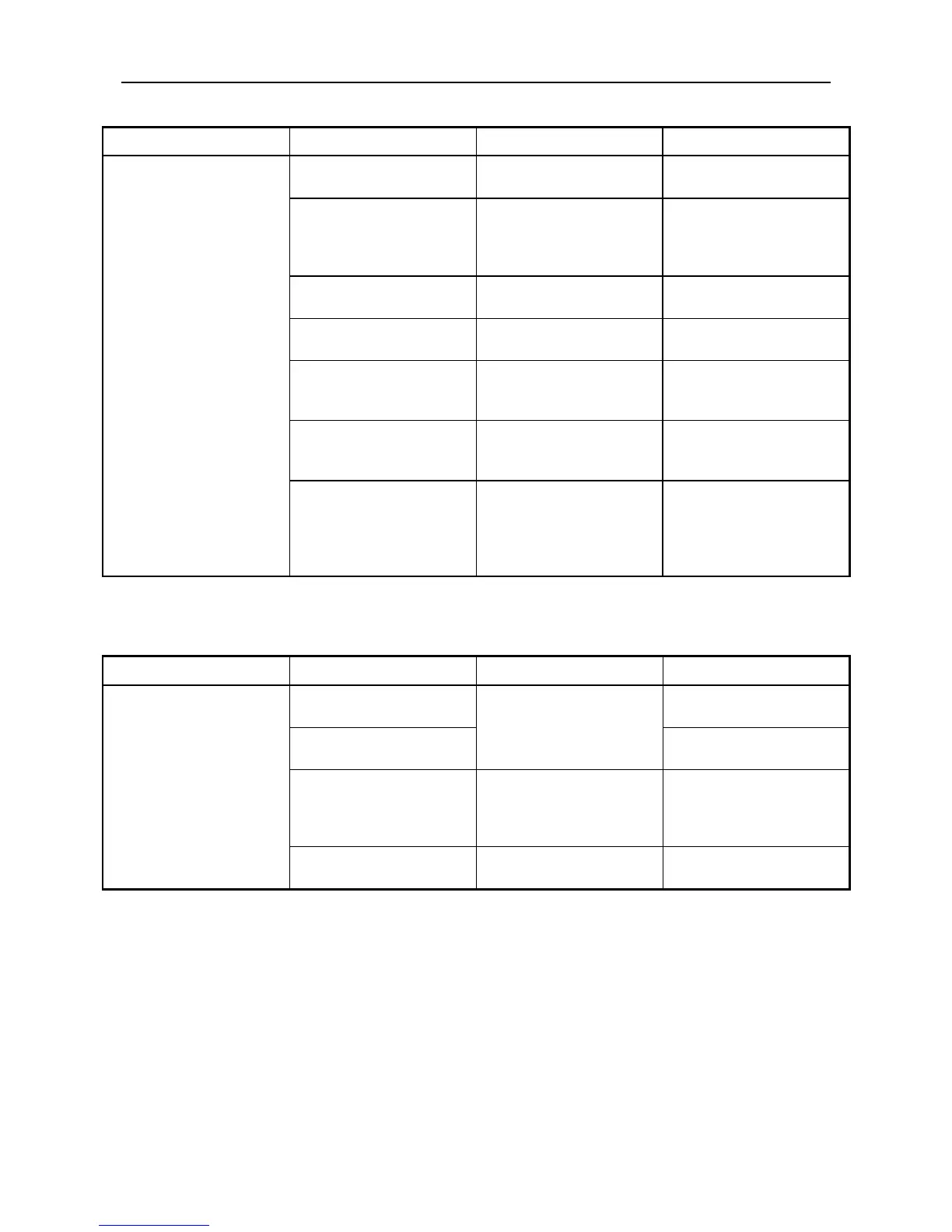

• Faulty sensor

Phenomenon Cause Check Method Remedy

Faulty paper sensor

Replace the SA SUB

PWB PE SENSOR.

Faulty paper near-end

sensor

Check whether the

ERROR LED flickers if

paper expires.

Replace the SA PNE

SENSOR.

Foreign substance is

attached to the paper

sensor

Check whether any

foreign substances are

adhered to the paper

sensor.

Remove the foreign

substance.

Failed detection of paper

feed

Failed detection of

paper’s near-end

Faulty connection of the

paper sensor connector

Check the connector

connection.

Connect the connector

correctly.

Loading...

Loading...