CFC-E Installation Manual

Part No. 750-459 1-7

A pre-start “boil out” of the vessel is not required; the interior boiler surfaces are cleaned following

production of the pressure vessel.

1.3.2 - Retrofit Installations

Older hydronic systems often contain impurities due to deteriorating piping, fittings, and other hydronic

specialties. Corrosion and sludge deposits in old systems must be removed prior to installation

of the new boiler to ensure existing debris does not enter the new boiler.

After the system is cleaned with the boiler isolated, and the new boiler is installed, a side-stream filter

is recommended for continuous removal of suspended and dissolved solids that could remain. For

assistance with selection and installation of a suitable filter, consult your water treatment provider.

If the system contains a significant amount of suspended or dissolved iron, a magnetic filter is

recommended.

1.4 - Using Glycol

The Model CFC-E boiler may be operated with a solution of glycol and water. Where glycol is added,

the system must first be cleaned and flushed. Correct glycol selection and regular monitoring of the in-

use concentration and its stability is essential to ensure adequate, long-term freeze protection,

including protection from the effects of glycol-derived corrosion resulting from glycol degradation.

Typically, ethylene glycol is used for freeze protection, but other alternatives exist, such as propylene

glycol. Glycol reduces the water-side heat capacity (lower specific heat than 100% water) and can

reduce the effective heat transfer to the system. Because of this, design flow rates and pump selections

should be sized with this in mind.

Generally, corrosion inhibitors are added to glycol systems. However, all glycols tend to oxidize over

time in the presence of oxygen, and when heated, form aldehydes, acids, and other oxidation products.

Whenever inadequate levels of water treatment buffers and corrosion inhibitors are used, the resulting

water glycol mixture pH may be reduced to below 7.0 (frequently reaching 5) and acid corrosion results.

Thus, when pH levels drop below 7.0 due to glycol degradation the only alternative is to drain, flush,

repassivate, and refill with a new inhibited glycol solution.

The following recommendations should be adhered to in applying ClearFire

®

model CFC-E boilers to

hydronic systems using glycol:

1) Maximum allowable antifreeze proportion (volume%):

50% antifreeze (glycol)

50% water

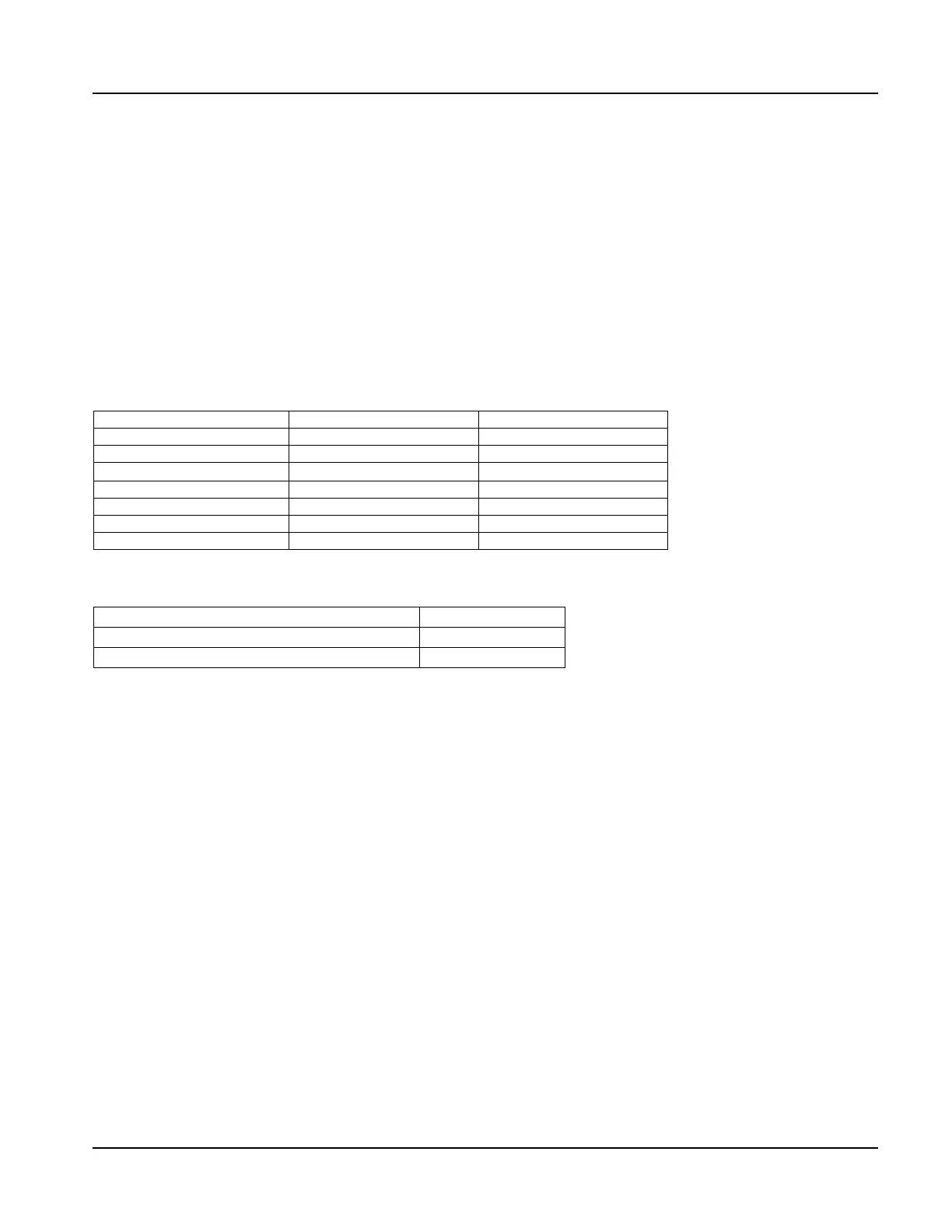

Table 1-2: Model CFC-E Water Chemistry

Parameter Limit Means of control

Glycol 50% Glycol fill/mixing station

pH 8.3 - 10.5 Buffering agent

Sulfates 50 ppm

Chemical additives

Chloride < 250 ppm RO filtration; Ion exchange

Oxygen < 0.1 ppm Air separator/eliminator

Specific Conductivity < 1500 mmho/cm

Total Hardness < 10 ppm Softener

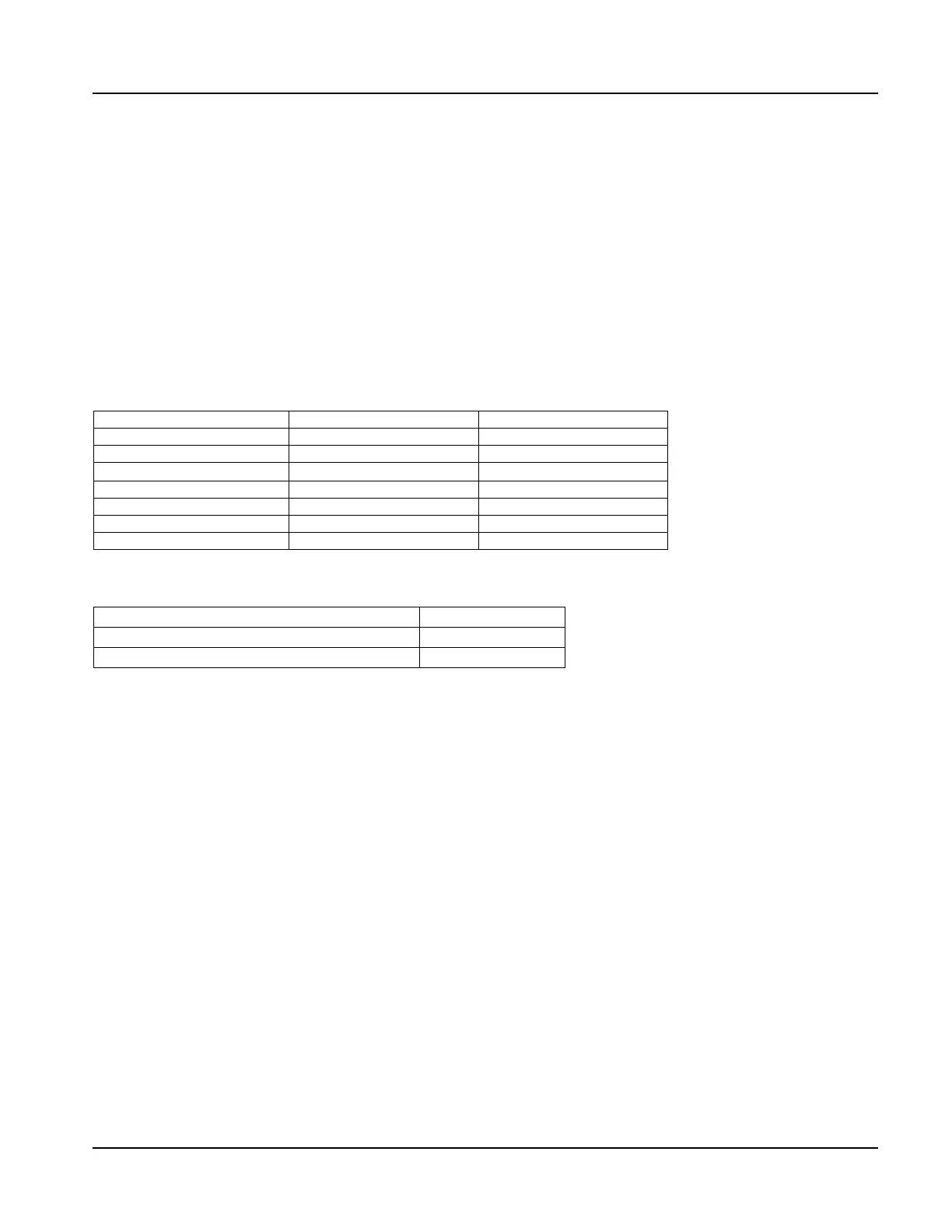

Table 1-3: CFC-E Water Temperature

Minimum inlet temperature 33

o

F

Maximum operating supply setpoint temperature 194

o

F

Maximum design temperature 210

o

F

Loading...

Loading...