CFC-E Installation Manual

Part No. 750-459 2-15

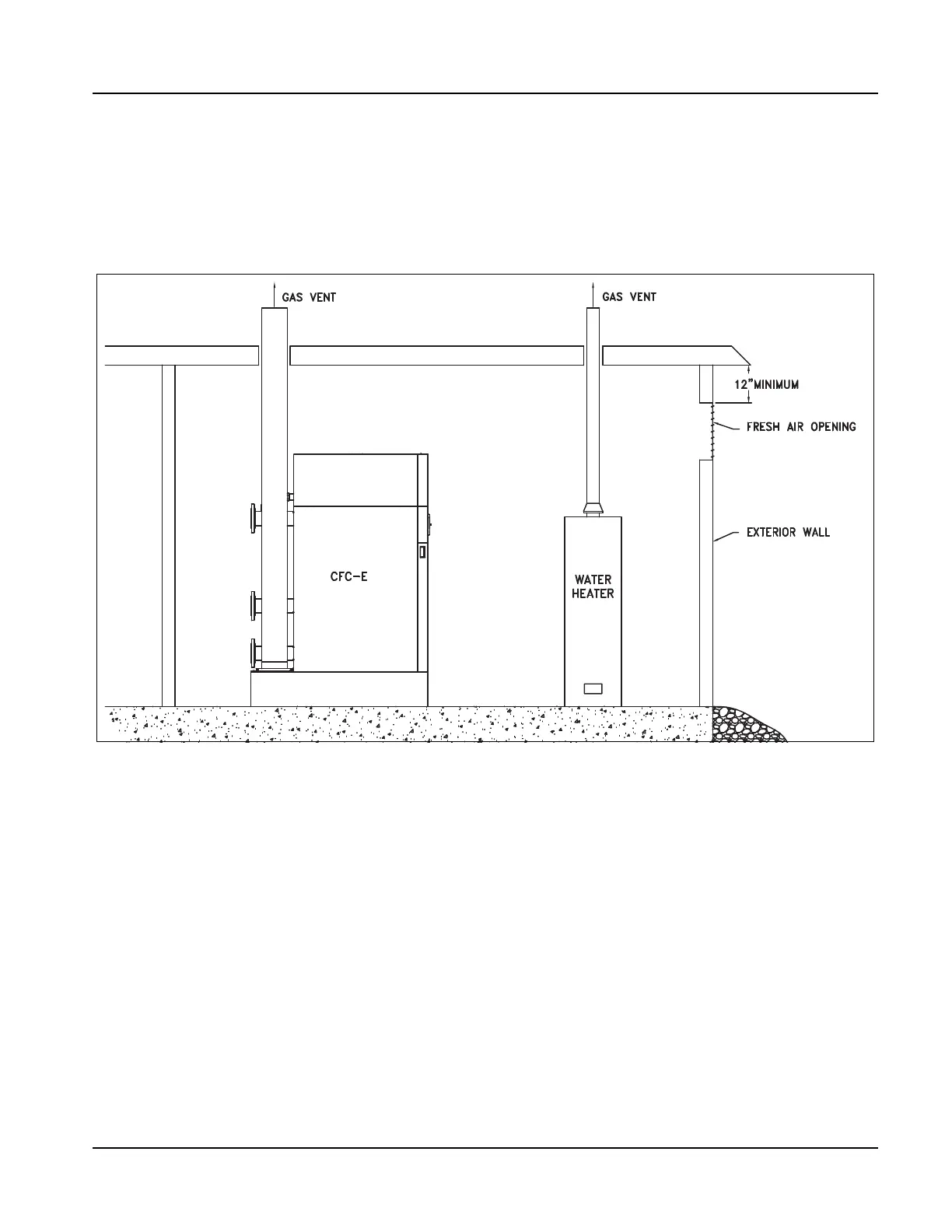

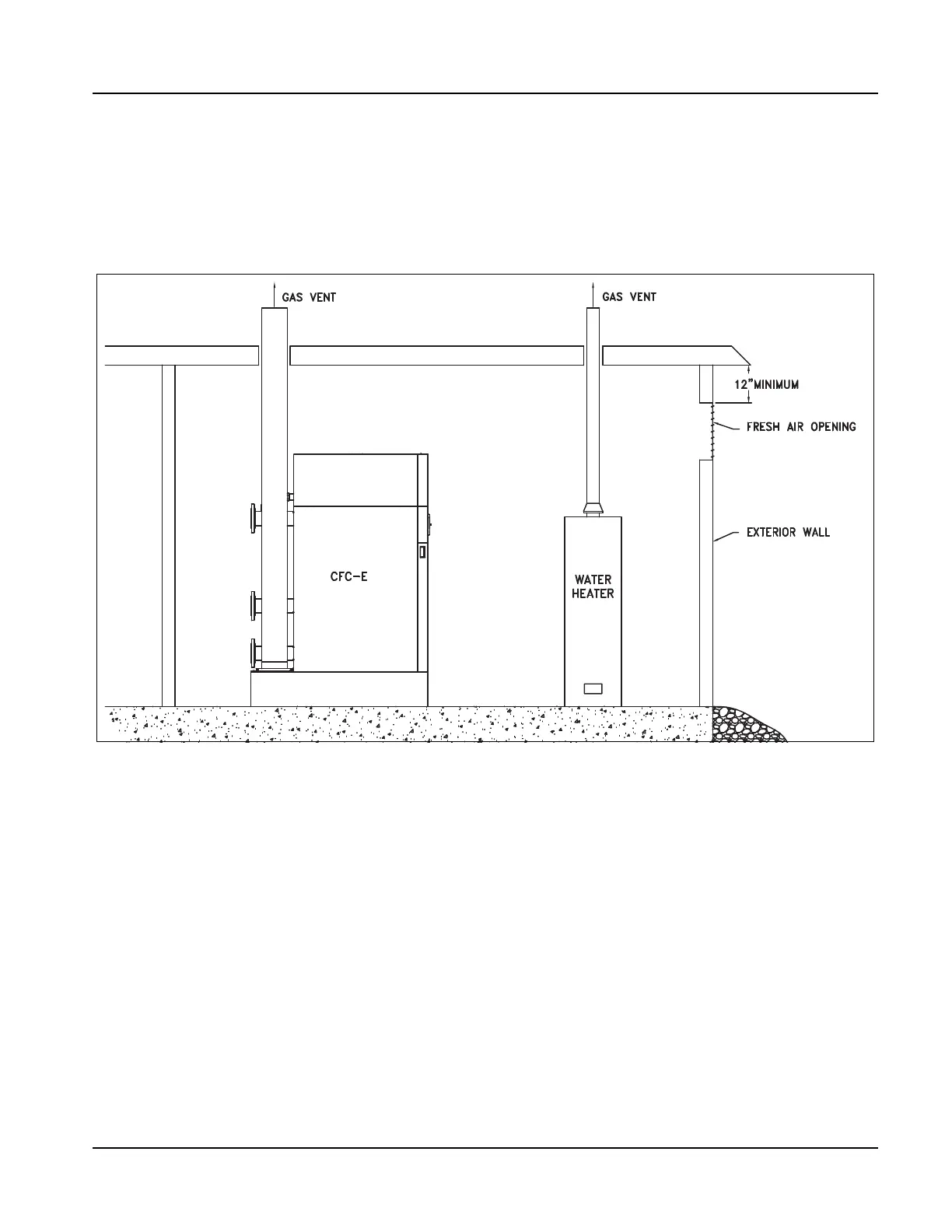

C. One Opening Method (Figure 2-9) - One permanent opening, commencing within 12 inches of

the top of the enclosure, shall be provided.

1. The equipment shall have clearances of at least 1 inch from the sides and back and 6 inches from the front of the

appliance.

2. The opening shall directly communicate with the outdoors and shall have a minimum free area of 1 square inch per

3000 BTU's per hour of the total input rating of all equipment located in the enclosure, and not less than the sum

of the areas of all vent connectors in the confined space.

3. Refer to the NFGC, Section 8.3 for additional information.

Figure 2-9 One Opening Method

2.8.2 - Air Supply - Engineered Method

When determining boiler room air requirements for an unconfined space, the size of the room, airflow,

and velocity of air must be reviewed as follows:

1. Size (area) and location of air supply openings in the boiler room.

A. Two permanent air supply openings in the outer walls of the boiler room are recommended. Locate one at

each end of the boiler room, preferably below a height of 7 feet. This allows air to sweep the length of the

boiler. See Figure 2-10.

B. Air supply openings can be louvered for weather protection, but they should not be covered with fine mesh

wire, as this type of covering has poor air flow qualities and is subject to clogging with dirt and dust.

C. A vent fan in the boiler room is not recommended, as it could create a slight vacuum under certain

conditions and cause variations in the quantity of combustion air. This can result in unsafe burner

performance.

D. Under no condition should the total area of the air supply openings be less than one square foot.

Loading...

Loading...