Chapter 2 ProFire Burner Operation and Control

2-4 750-177

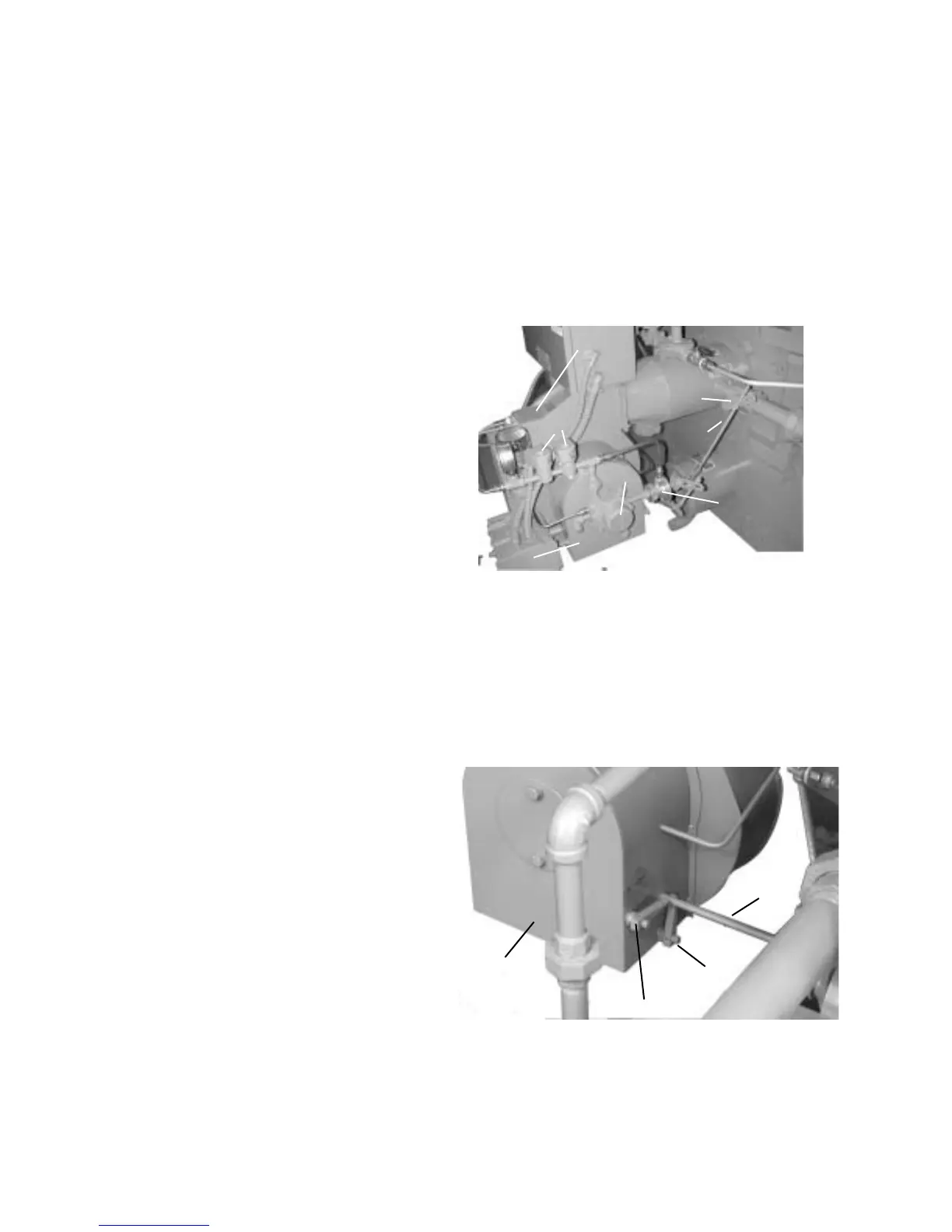

A. LOW-FIRE SHUTTER

B. HIGH-FIRE SHUTTER

C. AIRBOX

D. MAIN AIR SHUTTER SHAFT

providing air flow. The fuel supply valves will not open

if this switch does not sense adequate air pressure.

10. Impeller (Figure 2-4). The impeller is designed with

backwards-inclined vanes. It is located inside the blower

housing, and is driven by the combustion air fan motor.

The impeller provides combustion air to the burner

assembly. Removing the impeller requires the use of the

impeller puller, part number 943-388 (Figure 2-8)

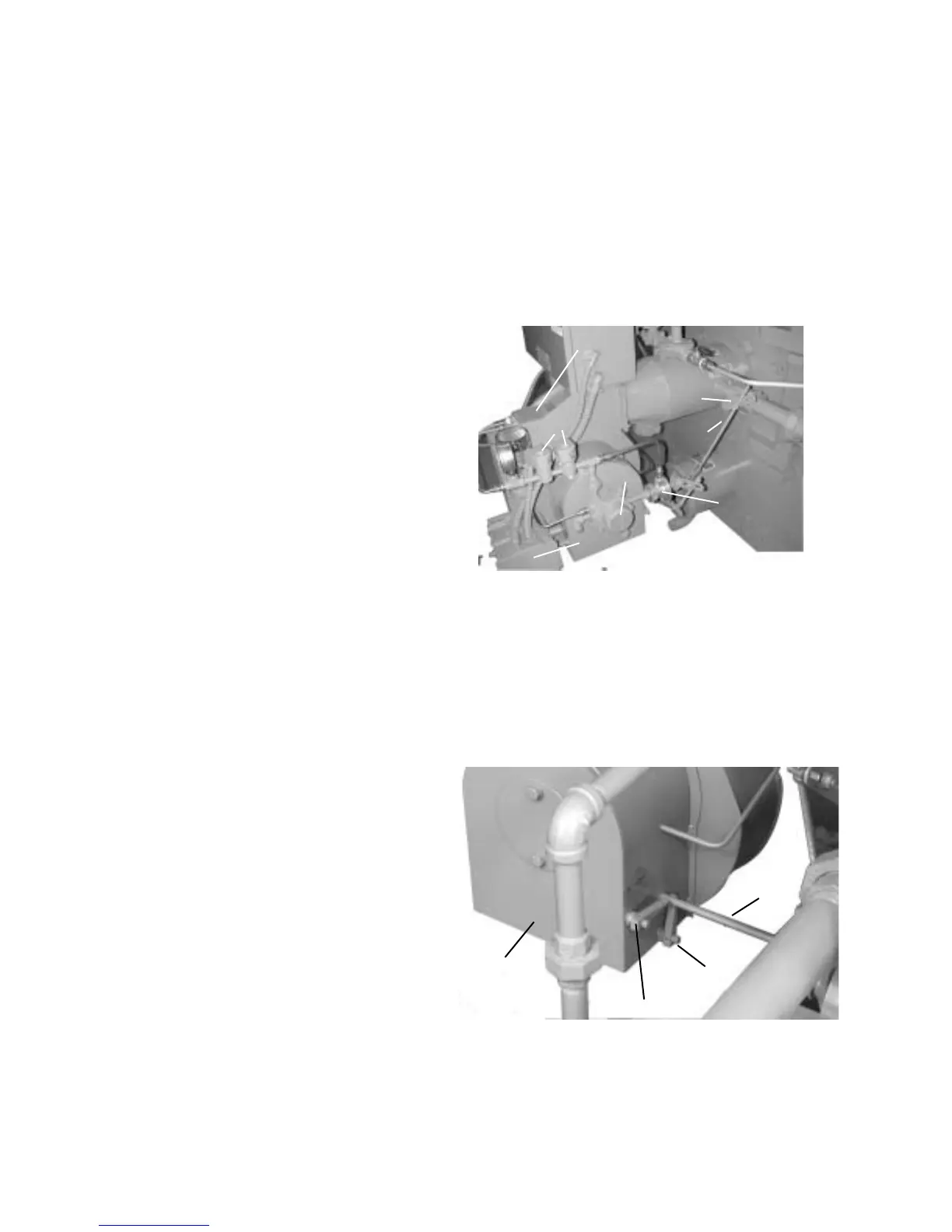

11. Gas Butterfly Valve (Figure 2-5). The gas butterfly valve

regulates the flow rate of natural gas into the burner. The

gas butterfly valve is connected, by linkage and a jack

shaft, to the modulating motor, which provides the rotary

motion to open and close the valve.

12. Valve Linkage (Figure 2-5). The valve linkage transfers

the modulating motion from the main air shutter shaft to

the fuel metering valve shafts. The linkage provides a

means of adjustment to maintain the correct fuel-to-air

ratio over the entire burner operating range, high fire to

low fire.

13. Oil Metering Valve (Figure 2-5). The oil metering valve

regulates the flow rate of oil into the burner. The oil

metering valve is connected by linkage and a jack shaft

to the modulating motor, which provides the rotary

motion to open and close the valve.

14. Oil Pump (Figure 2-5). The oil pump provided for oil

burning is coupled to an extension of the combustion air

fan shaft.

15. Modulating Motor (Figure 2-5). The modulating motor is

coupled to the jack shaft that operates the main air shutter

and the fuel valve linkages. The modulating motor

produces the torque and rotary positioning required for

firing rate control.

16. Oil Solenoid Valves (Figure 2-5). The oil solenoid

valves are in series and downstream of the oil metering

valve in the supply line to the oil burner assembly. Two

valves are provided. These valves are simultaneously

energized to open and release fuel oil to the burner. The

valves close to stop combustion when oil is the fuel.

17. Rear Cap (Figure 2-5). The rear cap contains the locking

setscrew for adjustment of the diffuser relative to the air

baffle, and also the flame scanner for the flame

safeguard. The rear cap must be removed to enable

removal of the oil gun assembly.

18. Low-Fire Shutter (Figure 2-6). The low-fire shutter

provides a means to set the correct combustion air flow

rate for low-fire operation. The handle indicates relative

shutter position.

19. High-Fire Shutter (Figure 2-6). The high-fire shutter

provides a means to set the correct combustion air flow

rate for high-fire operation. The handle indicates relative

shutter position.

A. GAS BUTTERFLY VALVE

B. VALVE LINKAGE

C. OIL METERING VALVE

D. OIL PUMP

E. MODULATING MOTOR

F. OIL SOLENOID VALVES

G. REAR CAP

A

B

C

E

Figure 2-5: Oil And Gas Piping To Burner

A

B

C

Figure 2-6: Airbox and Shutters

D

F

G

D

20. Airbox (Figure 2-6). The airbox is attached to the inlet side of

the fan housing. It serves as the inlet and flow regulating

valve for combustion air, and houses the combustion air

control shutters.

21. Main Air Shutter Shaft (Figure 2-6). The main air shutter

modulates the combustion air between low fire and high fire

conditions. The shaft connects the modulating motor to the

main air shutter and to the fuel valve linkage assemblies.

Loading...

Loading...