Chapter 5 STARTING AND OPERATING INSTRUCTIONS

5-14 750-177

13. Check intermediate positions for proper combustion.

Adjust the linkage, as required, to match the fuel and air

rates indicated in Table 5-2.

14. Modulate and recheck combustion air at different firing

rates. When large adjustments are made at one rate, they

may adversely affect settings at another rate.

E. BURNER ADJUSTMENTS,

COMBINATION GAS AND OIL

Note: The operator must consider and allow

for normal variations in air and fuel, which

would reduce the range of excessive

oxygen in the flue gas accordingly.

This section of the manual presents procedures to be followed

for initial startup of a combination ProFire burner.

!

DANGER

CAUTION

This burner is designed to burn only those fuels

shown on the burner data plate. Burning fuels

not specified on the data plate could cause

damage to the equipment.

These procedures assume that the pre-startup tasks,

checklists, and adjustments have been completed, and that the

boiler system is prepared for initial startup. All necessary test

equipment should be available on site.

In general, the combination fueled system is to be started first

using oil, because, as a fuel, oil has a greater combustion air

requirement than natural gas. After being completely

adjusted for oil combustion, the burner is re-started and

adjusted using natural gas as fuel. Combustion adjustment of

the combination burner for natural gas involves balancing the

input gas rates only against the existing flow of combustion

air, as established initially for oil-firing.

Do not readjust the

air shutters when tuning the combination burner for

combustion of natural gas.

!

DANGER

WARNING

Attempting initial burner startup with

insufficient knowledge of the equipment

and startup procedures can result in

serious damage. The operator must be

totally familiar with the entire startup and

adjustment process before attempting to

operate the burner.

CONTROLS SETUP. Complete the following system control

setup steps before beginning the combination burner startup

procedure:

1. Check the linkages to confirm that they are securely

fastened and ready for operation (see Figures 3-2 and 3-

4).

NOTE: The linkages have been factory-set and

tested, although they may require fine tuning for

the specific application. If the linkage is not in

place, or if the setting has been lost, install the

linkage in accordance with Figures 5-9 and 5-

11.

2. Place the burner switch in the OFF position.

3. Place the Modulating Mode switch in the MANUAL

position.

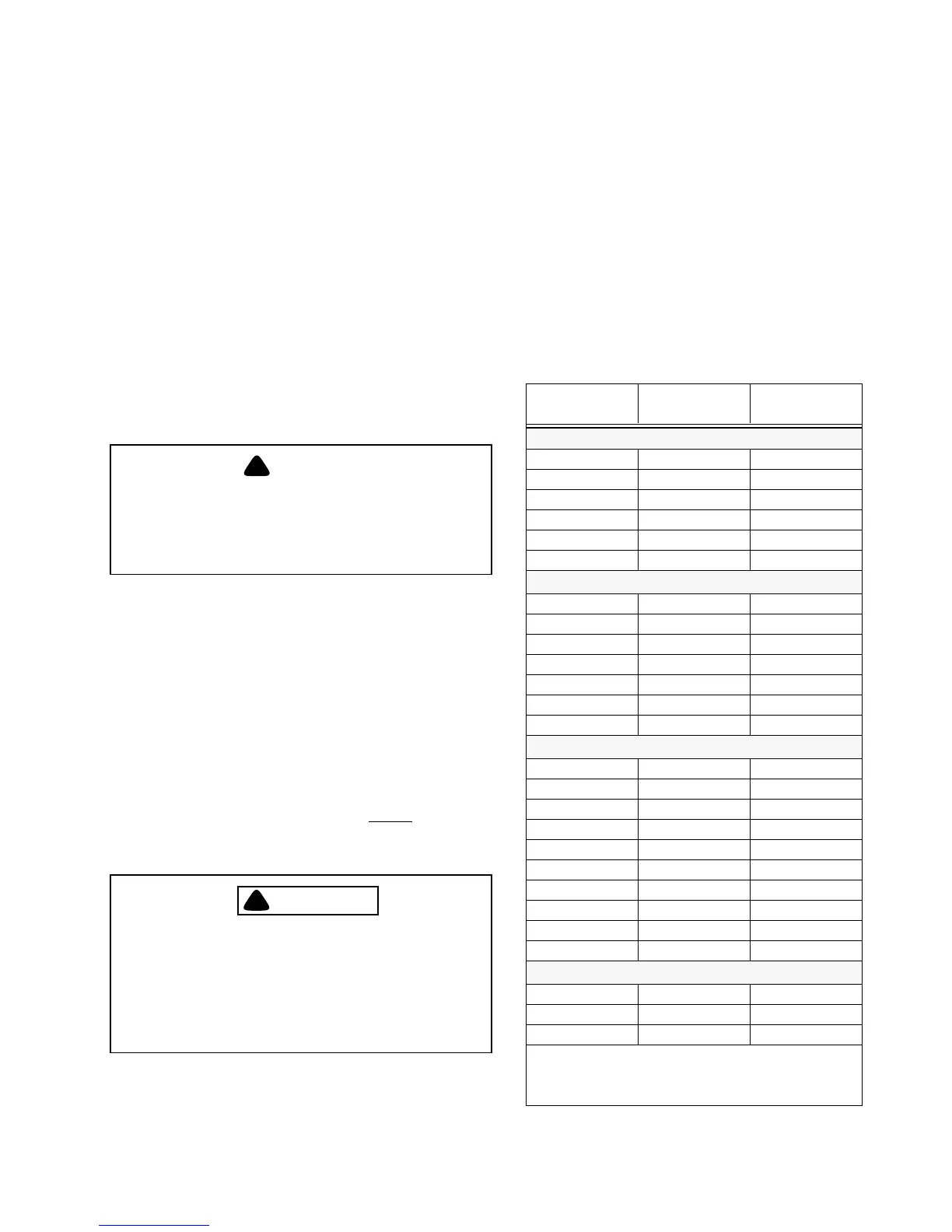

INPUT

(MMBtu/hr)

MINIMUM O2

(%)

MAXIMUM O2

(%)

SIZE 1

0.7 N/A N/A

0.9 4.0 9.5

1.0 4.0 9.5

1.5 2.5 8.0

2.0 2.0 5.0

2.5 2.0 5.0

SIZE 2

1.5 4.0 10.0

2.0 4.0 10.0

2.5 3.5 10.0

3.0 3.0 9.5

3.5 3.0 7.0

4.0 3.0 5.0

4.5 3.0 5.0

SIZE 3

4.5 3.0 8.5

5.0 3.0 8.5

5.5 2.5 8.0

6.0 2.5 7.0

6.5 2.0 6.0

7.0 2.0 5.0

7.5 2.0 5.0

8.0 2.0 5.0

8.5 2.0 5.0

9.0 2.0 4.5

SIZE 4

10.0 3.0 5.0

11.0 3.0 5.0

12.0 3.0 4.5

Note: Table presents the maximum recommended range of operating levels

of excess oxygen in the flue gas for various burner sizes, operating at given

levels of light oil input to the burner. Data is valid for conditions at standard

atmospheric temperature and pressure. Results will vary under environmen-

tal conditions differing from standard.

Table 5-2: Recommended Stack Gas O

2

Concentration At Various Rates (Light Oil)

Loading...

Loading...