STARTING AND OPERATING INSTRUCTIONS Chapter 5

750-177 5-5

B. STARTUP PROCEDURES

PRESTART TASKS AND CHECKLIST - ALL

FUELS

Before proceeding with system startup and adjustment, be

sure that overall installation is complete. Review the boiler

operating and installation manual set carefully to verify that

the boiler is properly set up for operation. Check that all

shipped-loose items (those items not installed when shipped)

have been correctly installed. Verify the supply of fuel. Check

to make sure the burner is wired as shown on the wiring

diagram. Ensure that all control wiring terminals are tight.

Complete the following checklist in preparation for system

startup:

• Confirm that the fuel and electrical connections have

been completed in accordance with the applicable codes

and insurance requirements (if necessary), and that con

-

nections comply with the piping schematic and wiring

diagram.

• Check the combustion air fan motor for correct rota-

tional direction.

• Check that the boiler is filled with water to the proper

level, and that all circulating pumps (hot water units) are

correctly installed and operational.

• Verify that there is proper gas pressure at the gas train,

if this is a gas or combination burner. See the burner

specification plate (Figure 5-8) for minimum and maxi

-

mum natural gas pressure requirements.

• For oil burners confirm that the oil tank is adequately

filled with the correct grade of fuel oil, and that any iso

-

lation valves in the supply and return lines are open.

• Check that the flame safeguard has been properly in-

stalled inside the control panel.

• Provide the following test equipment on site:

1) Combustion analyzer for O

2

.

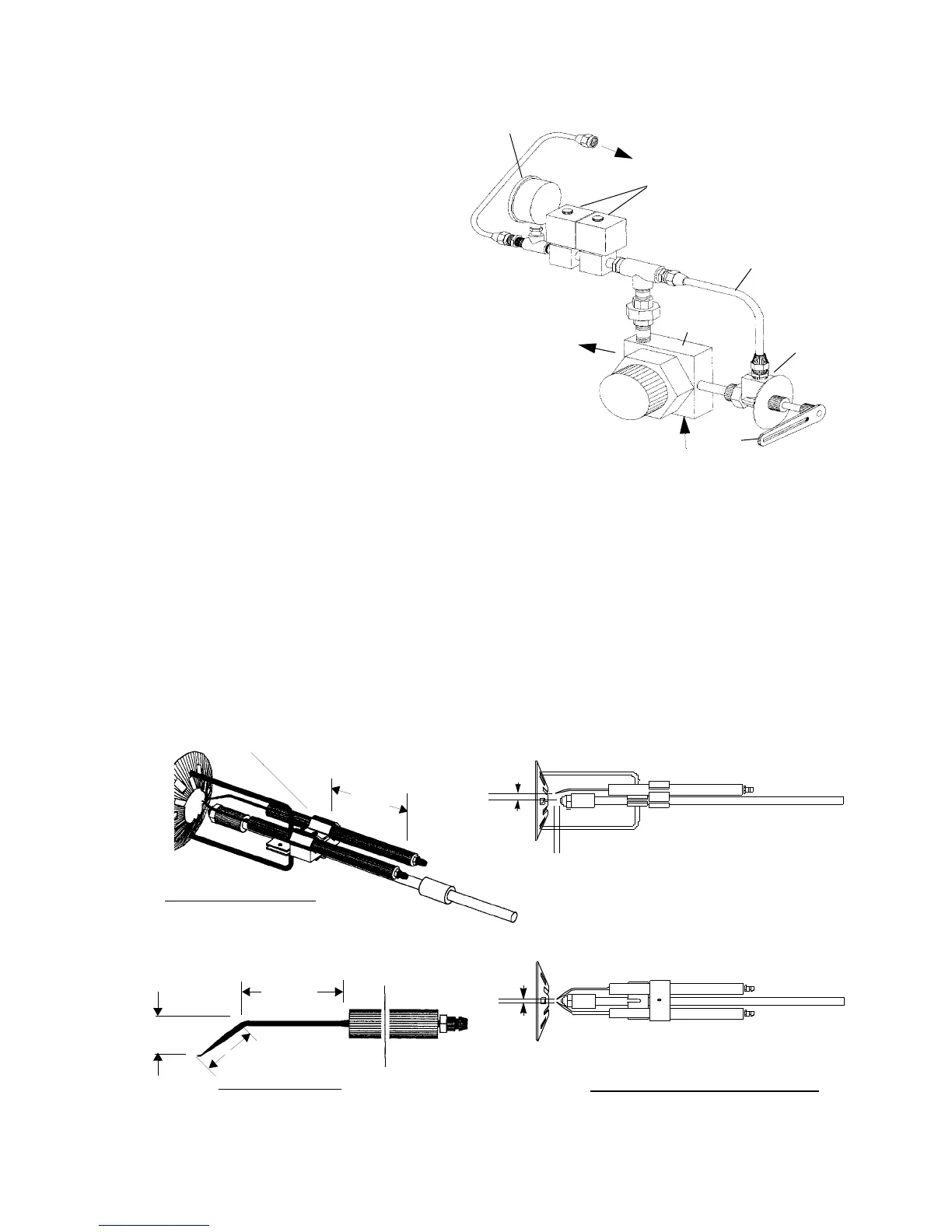

OIL PRESSURE

GAUGE

OIL SOLENOID VALVES

OIL BYPASS

OIL

VALVE

OIL PUMP

OIL TO BURNER

OIL SUPPLY INLET

EXCESS OIL

RETURN TO TANK

Figure 5-4: Oil Piping Schematic

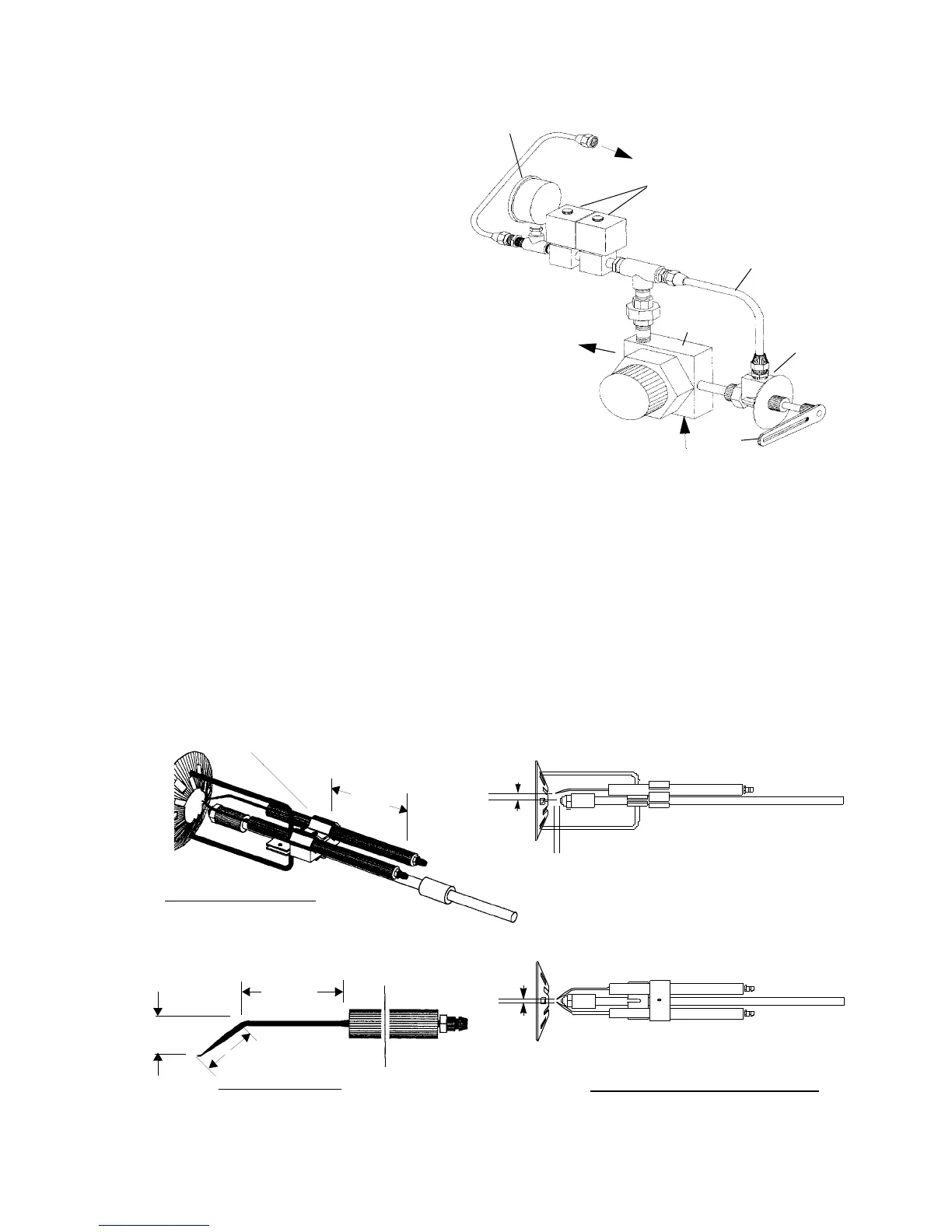

TUBING

METERING

OIL

VALVE

ARM

SPARK IGNITION CLAMP

MOUNTED ELECTRODES

SET GAP 1/8

SET GAP 7/16”

ELECTRODES - TO NOZZLE POSITION

ELECTRODE SHAPE

19/32

1

1-15/16

3-1/2

1

Figure 5-5: Direct Spark Ignition Electrode Adjustment Dimensions

ABOVE CENTER

LINE OF NOZZLE

BETWEEN

ELECTRODES

SET GAP 1/4”

AHEAD OF NOZZLE

Loading...

Loading...