Chapter 5 STARTING AND OPERATING INSTRUCTIONS

5-4 750-177

4. Carefully install the adjusted nozzle/diffuser assembly

into the burner. Then re-connect the oil supply and high-

voltage power cable to the assembly.

5. The diffuser-to-air baffle dimension “B” must now be

checked and adjusted (see Figure 5-6 for correct

dimension). Check and adjust to dimension “B” as

follows:

A.Open the burner mounting door on the boiler. Swing

the burner out to expose the diffuser and air baffle.

B. Measure the distance between the leading edge of the

diffuser and the front face of the inner ring on the air

baffle assembly.

C. If adjustment is required, loosen the burner pipe

locking setscrew (located on the rear cap at the top of

the fan housing) and slide the burner pipe in or out to

achieve the correct “B” dimension.

D.Tighten the oil pipe locking setscrew securely.

E. Swing the burner and mounting door into the closed

position on the boiler and fasten the door securely.

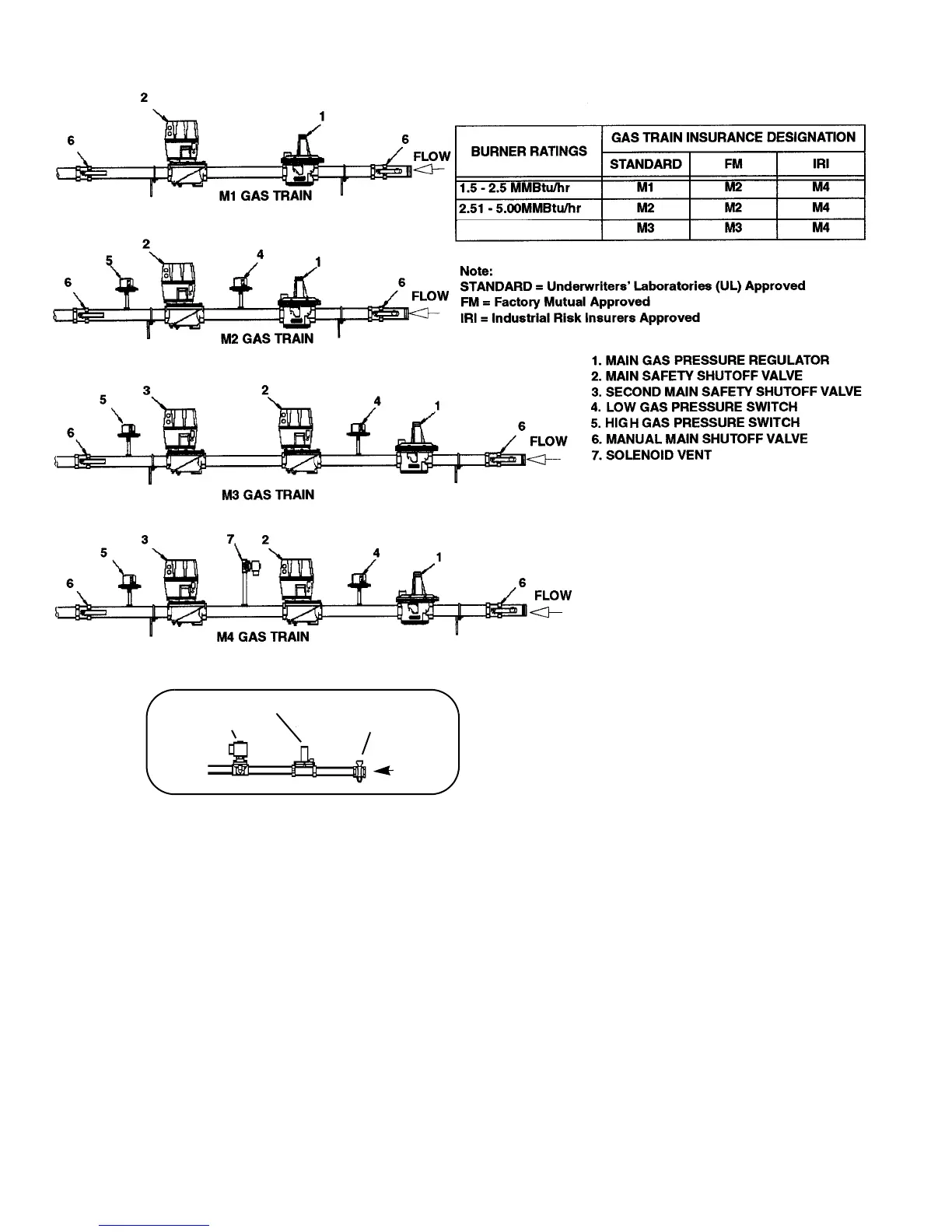

FLOW

MANUAL

PRESSURE REGULATOR

SOLENOID VALVE

Figure 5-3: Pilot Gas Train

PILOT STOPCOCK

B. Rotate and slide each electrode in the clamp, as necessary,

to achieve the correct position relative to the burner tip.

C. Tighten the locking screws securely to lock the electrodes

in position. Apply a lock-tight type compound to the

screws before tightening.

3. Refer to Figure 5-7 and measure the distance from the tip of

the nozzle to the diffuser (Dimension “A”). If necessary,

adjust the position of the diffuser as follows:

A.Loosen the locking screws on the diffuser clamp.

B. Slide the diffuser clamp along the length of the burner pipe

until the correct dimension is achieved.

C. Tighten the diffuser clamp securely to the burner pipe.

Apply a Lock-tight type compound to the screws before

tightening.

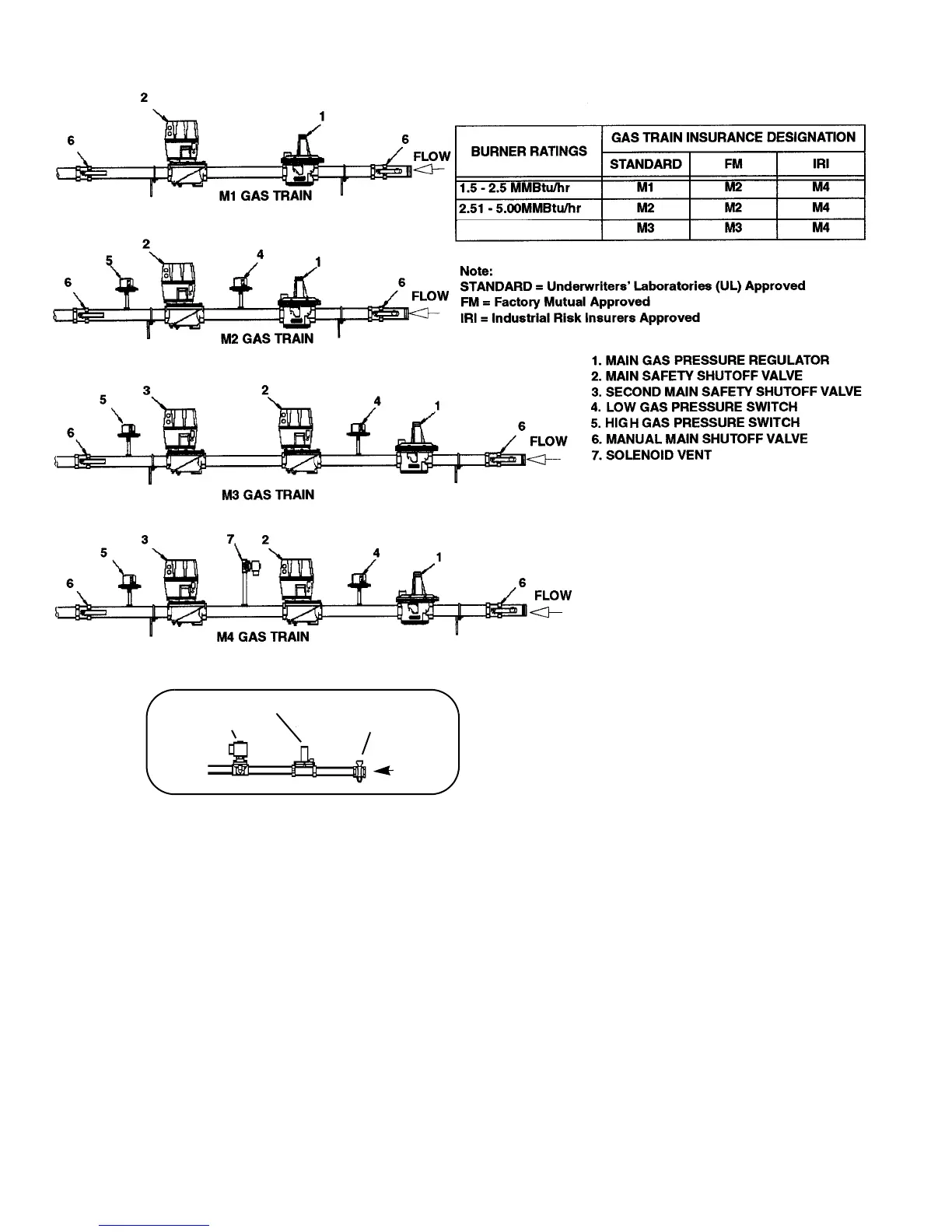

Note: Gas train

configurations are subject

to change. The above

configurations reflect

components at the date of

this Operation and

Maintenance manual

publication date.

5.01 - 12.00 MMBtu/hr

Loading...

Loading...