STARTING AND OPERATING INSTRUCTIONS Chapter 5

750-177 5-3

!

DANGER

WARNING

Inadvertent burner operation can cause

serious injury, or death. Do not perform

maintenance on a burner without first

disabling the electrical power supply. Lock

out and tag the electrical power supply to

prevent inadvertent burner startup during

checkout or maintenance activities. Failure

to follow these instructions could result in

serious personal injury or death.

A.Lock out and tag the electrical power supply to the

burner to prevent inadvertent operation during

checkout or maintenance activities.

B. Disconnect the high-voltage power supply from the

oil-spark-ignition electrodes (if installed).

C. Disconnect the oil piping from the end of the blast

tube.

D.Remove the fasteners that secure the nozzle/diffuser

assembly to the top of the fan housing, and remove the

nozzle/diffuser assembly from the burner.

2. Measure the position and gap of the pilot electrodes, and

compare these to the dimensions shown in Figure 5-5. If

necessary, adjust the position of the electrodes relative to

the nozzle as follows:

A.Loosen the locking screws on the spark ignition clamp

assembly (Figure 5-5).

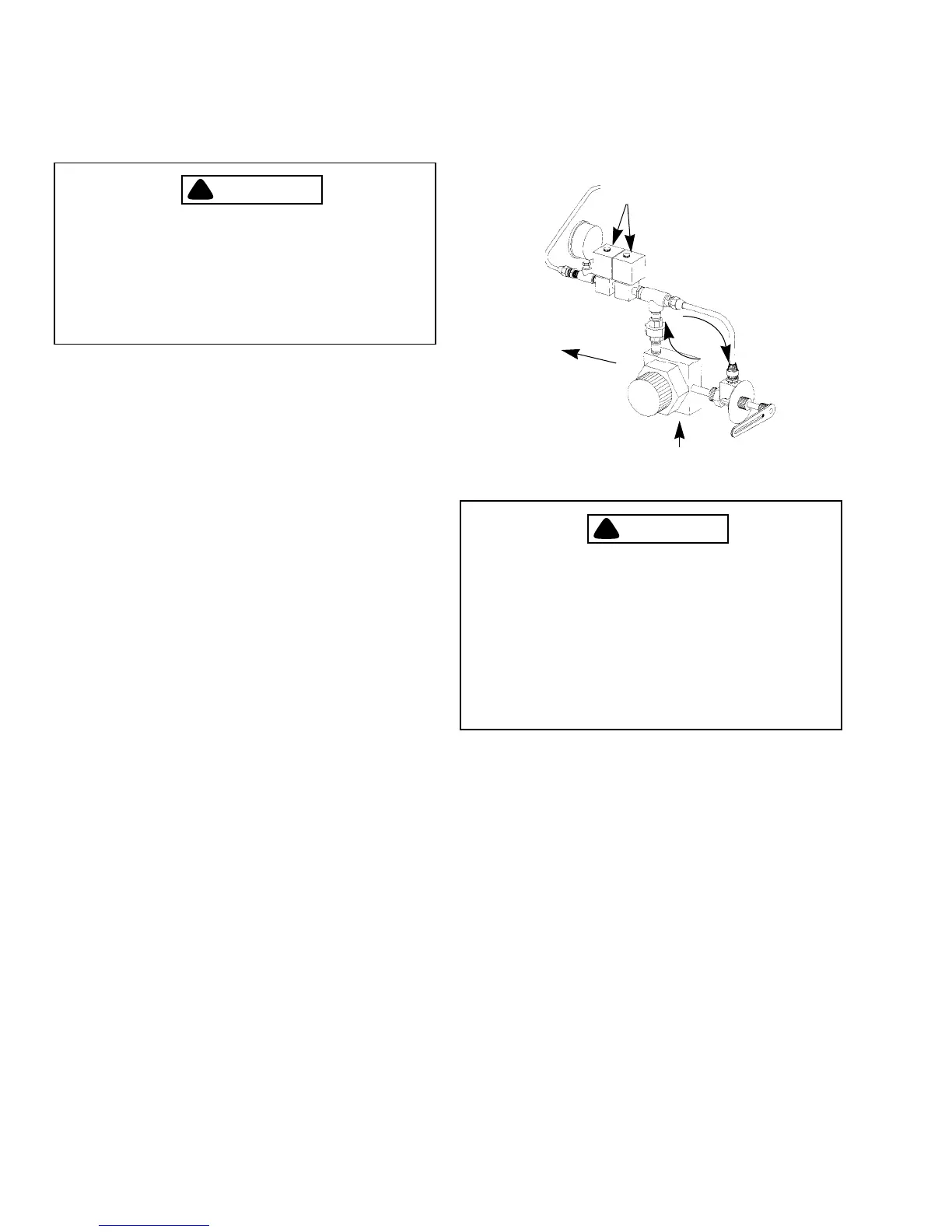

Figure 5-2: Oil Pump Circulation

OIL SOLENOID

VALVES (CLOSED)

OIL SUPPLY INLET

EXCESS OIL RETURN TO

TANK

OIL CIRCULATION

BURNER OFF FAN ON

3. ELECTRICAL REQUIREMENTS AND

CONNECTIONS

!

DANGER

WARNING

Shut off and lock out all electrical power to

the burner before performing any service or

maintenance that requires removal of

electrical equipment covers or component

parts. Failure to follow these instructions

could result in serious personal injury or

death.

Verify that all electrical power supplies and branch circuit

wiring are sized in accordance with the electrical loads shown

on the specification plate on the side of the burner control

cabinet (Figure 5-8). Check system interlocks, control

interfaces, and any additional remote controls against the

system schematic and wiring diagram. Refer to the Cleaver-

Brooks wiring diagram supplied with the burner for specific

requirements. Verify that all supply wiring terminations are

tight.

4. LINKAGE CONNECTIONS

Inspect all linkages for damage and/or loosening during

shipment. All fasteners must be secure for safe operation. All

connections must be correctly positioned and tightened

(Figure 5-9 and 5-11). Apply a lock-tight type compound to

any fasteners after adjustment.

5. BURNER SETTINGS

To ensure reliable and safe burner performance, the location

and gap setting of the electrodes for the direct-spark igniters,

and the relative positions of the burner nozzle, diffuser, and

air baffle components must be correctly set (Figures 5-5, 5-6

and 5-7). Normally these items are preset at the factory, but

must be checked prior to placing the burner into initial

service, or after conducting any service work that may have

altered their positions.

The nozzle/diffuser assembly must be removed from inside

the burner to enable measurement and adjustment of the oil-

spark-ignition electrodes (furnished only on oil burners) and

the nozzle relative to the diffuser.

1. Remove the nozzle/diffuser assembly as follows:

Loading...

Loading...