Chapter 5 STARTING AND OPERATING INSTRUCTIONS

5-12 750-177

CONTROLS SETUP. Complete the following combination

system control setup steps before beginning the oil-fired

burner startup procedure:

1. Check the linkages to confirm that they are securely

fastened and ready for operation (see Figure 5-11).

NOTE: The linkages have been factory-set

and tested, although they may require fine

adjustment for the specific application. If

the linkage is not in place, or if the setting

has been lost, install the linkage in

accordance with Figure 5-11.

2. Place the burner switch to the OFF position.

3. Place the Manual/Auto mode switch to the MANUAL

position.

4. Place the manual flame control potentiometer to the

CLOSED (low-fire) position.

5. Check the presetting of the air shutters. (If the linkage is

loose and no pre-settings are available, start with the

shutter in the full open position).

6. When a gas pilot is used, open the valve in the gas pilot

line.

STARTUP. Proceed with initial startup of the oil-fired system

as follows:

1. Turn on the electrical power for the burner, boiler, and

related components.

2. Verify that the oil metering valve is nearly open.

NOTE: Opening the oil metering valve

reduces oil flow to the burner.

3. Turn the burner switch on. This will start the blower

motor and initiate the prepurge sequence.

4. When the prepurge sequence ends, the pilot valve will

open. The pilot flame should be visible from the viewing

window.

NOTE: If the pilot is established, the flame

safeguard will energize the two oil solenoid

valves (this is accompanied by a click from

the solenoid valves and illumination of the

FUEL VALVE light) and the oil burner should

ignite on low-fire.

5. After the main flame has been established, the oil

pressure entering the burner nozzle should be read (by

reading the oil pressure gauge downstream of the oil

solenoid valves) to get an initial estimate of the fuel oil

input rate. Oil pressure should be about 80 psi when

operating at low-fire. Adjust the oil metering valve if the

actual pressure is not within the range of 80 to 90 psi.

6. Operate the boiler at low fire until it is thoroughly

warmed. Then, modulate to high fire by turning the

manual flame potentiometer to the OPEN position. This

will cause the oil metering valve to close, resulting in an

increase in the oil pressure feeding the burner nozzle.

Check the excess air in the flue gas (see Table 5-2 for

acceptable O

2

levels), while modulating to high-fire.

Adjust the oil pressure if needed.

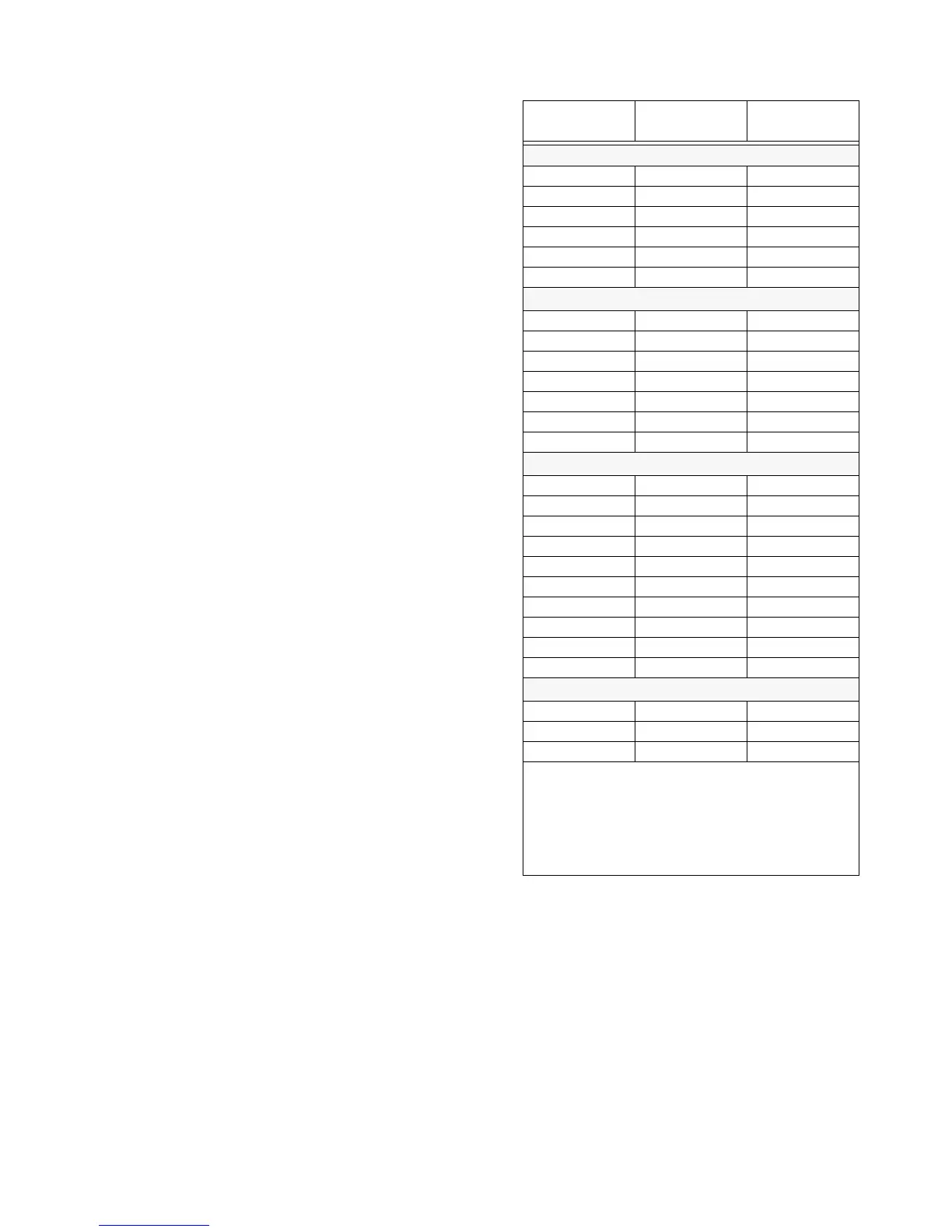

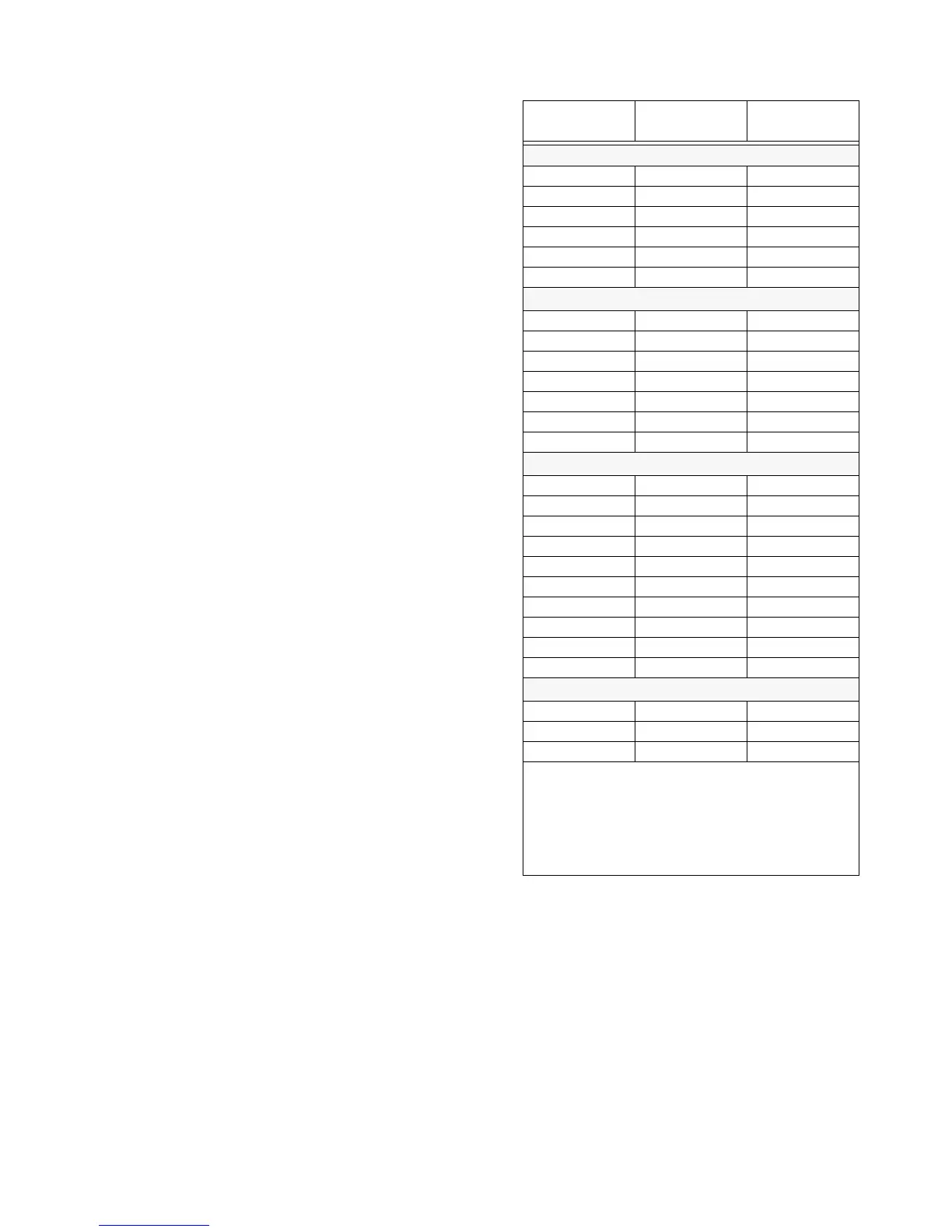

INPUT

(MMBtu/hr)

MINIMUM O

2

(%)

MAXIMUM O

2

(%)

SIZE 1

0.7 3.0 9.0

0.9 3.0 9.0

1.0 3.0 9.0

1.5 2.5 9.0

2.0 2.0 5.5

2.5 2.0 5.0

SIZE 2

1.5 3.0 8.0

2.0 3.0 8.0

2.5 3.0 8.0

3.0 3.0 8.0

3.5 3.0 7.0

4.0 3.0 5.0

4.5 3.0 5.0

SIZE 3

4.5 2.5 7.5

5.0 2.5 7.5

5.5 2.5 7.0

6.0 2.5 6.5

6.5 2.5 6.0

7.0 2.5 5.5

7.5 2.5 5.0

8.0 2.5 5.0

8.5 2.5 5.0

9.0 2.0 4.5

SIZE 4

10.0 2.5 5.0

11.0 2.5 5.0

12.0 2.0 4.5

Note: Table presents the maximum recommended range

of operating levels of excess oxygen in the flue gas for

various burner sizes, operating at given levels of natural

gas input to the burner. Data is valid for conditions at stan-

dard atmospheric temperature and pressure. Results will

vary under environmental conditions differing from stan-

dard.

Table 5-1: Recommended Stack Gas 0

2

Concentration at Various Rates (Natural Gas)

Loading...

Loading...