Model 4

1500 - 6000 MBTU/hr

Rev. 03-08

Section B2-17

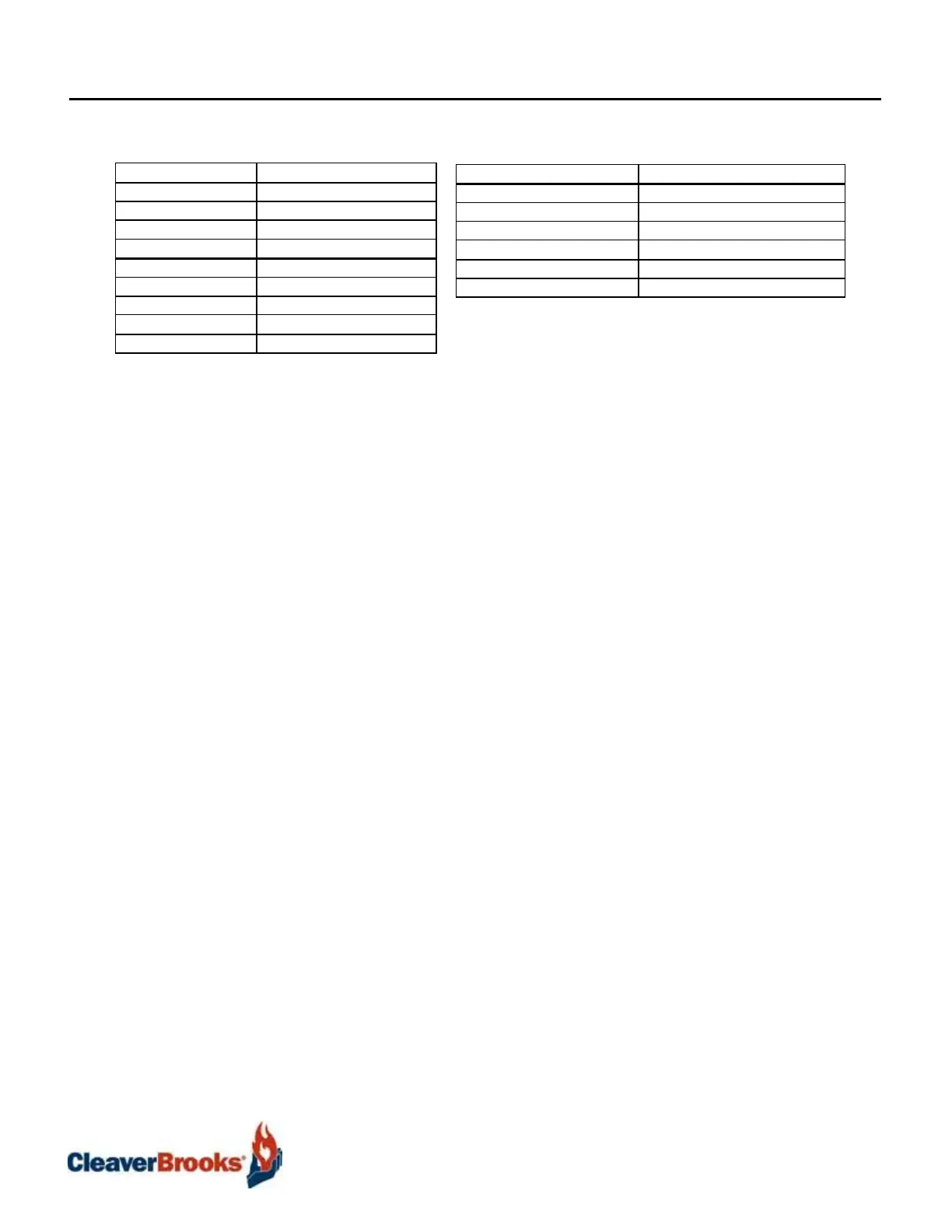

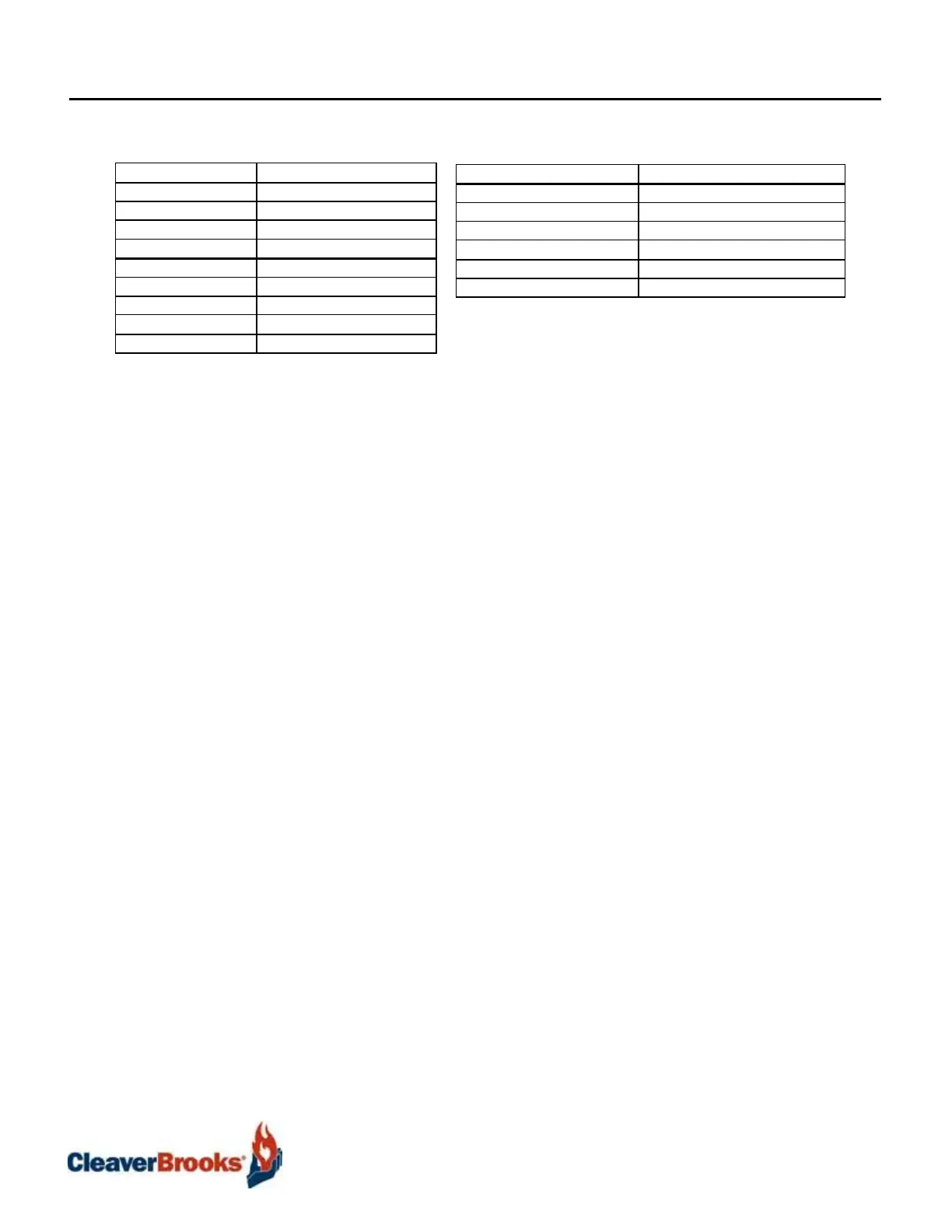

Parameter

Boiler Water

Limit

pH

8.3 -

10.5

Iron

0.1

ppm

Ox

ygen

0.1

mg/liter

Specific

Conductivity

2000

µ

mho/cm

Suspended

Solids

300

ppm

Total

Hardness

0 ppm as

CaC

O

3

Table

B2-13.

Feedwater makeup

rates

Table

B2-14.

Water quality

parameters

Boiler

Size

Gallons/Minute

1500

2.5

2000

3.3

2500

4.1

3000

5

3500

5.8

4000

6.6

4500

7.5

5000

8.3

6000

9.9

Blowdown As steam is produced, unwanted solids are left behind in the boiler water and

become concentrated

within the vessel. If

these constituents

are

allowed

to adhere

to the heat transfer

surfaces,

they will impede the flow of

energy

into the water.

Their removal requires proper blowdown that will include bottom and possibly

surface blowoff. For proper

TDS

control, surface blowoff with a TDS monitoring

device is recommended. Local codes will dictate the manner of treating the

blowdown affluent.

Boiler Stacks

General

- The Model 4 boiler

operates

with a

positive

vent

pressure

and a vent gas

temperature that is

non-condensing.

Therefore, the stack must be a positive

pressure

design.

Proper design

and installation of the flue

gas venting

is critical to efficient and safe

operation of the burner. The vent should be

designed

with proper supports and

clearances

from

combustible

materials. Use insulated vent pipe

spacers

where the

vent

passes through

walls and roofs.

The design

of the

stack

and

breeching

must

provide

the

required

draft at

each

boiler

stack connection.

Although constant pressure

at the flue

gas

outlet is not required,

it is

necessary

to

size

the

breeching

and stack to limit flue

gas pressure

variations.

Consideration

of the draft must be given where lengthy runs of breeching or

unusually

high

stacks

are employed.

Please

note: the

allowable pressure range

for

design

of the

stack

and

breeching

is

negative

0.25

"

w.c. (-62

Pa)

to a

positive

0.25"

w.c. (+62

Pa)

for

proper

light

offs

and

combustion.

NOTE:

This pressure range

does

not pertain to the boiler room; that is, the boiler room must be neutral or slightly

positive, never negative

when

using

air from the boiler

room

for combustion.

When two or more Model 4 boilers are

connected

to a common

breeching/stack,

one should

evaluate

the

affects

of

pressure variations

that may occur during boiler

sequencing while boilers are firing. It may be determined that some type of

mechanical draft system be employed to ensure proper draft at each boiler is

maintained.

Combustion Air

-

The burner

for

each boiler

must be

supplied

with

adequate

volume

of

uncontaminated

air to support

proper combustion

and

equipment

ventilation. Air

shall be free of chlorides, halogens, fluorocarbons, construction dust or other

contaminants

that

are detrimental

to the

burner

or boiler

heating

surfaces.

Combustion

air can be supplied by means of

conventional

venting, that is,

with

combustion air drawn from the area immediately

surrounding

the boiler (boiler

Loading...

Loading...