Tranquility

®

Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

12

Geothermal Heat Pump Systems

Evacuation and Charging the Unit

LEAK TESTING -

The refrigeration line set must be pressurized

and checked for leaks before evacuating and charging the unit.

To pressurize the line set, attach refrigerant gauges to the service

ports and add an inert gas (nitrogen or dry carbon dioxide) until

pressure reaches 60-90 psig [413-620 kPa]. Never use oxygen

or acetylene to pressure test. Use a good quality bubble solution

to detect leaks on all connections made in the fi eld. Check the

service valve ports and stem for leaks. If a leak is found, repair it

and repeat the above steps. For safety reasons do not pressurize

system above 150 psig [1034 kPa]. System is now ready for

evacuation and charging.

Condensate Drain Tubing

Consult local codes or ordinances for specifi c requirements.

IMPORTANT: When making drain fi tting connections to the

drain pan, use a thin layer of Tefl on paste, silicone or Tefl on

tape and install hand tight.

IMPORTANT: When making drain fi tting connections to drain

pan, do not overtighten. Overtightening fi ttings can split pipe

connections on the drain pan.

• Install drain lines so they do not block service access

to front of the unit. Minimum clearance of 24 inches is

required for fi lter, coil or blower removal and service

access.

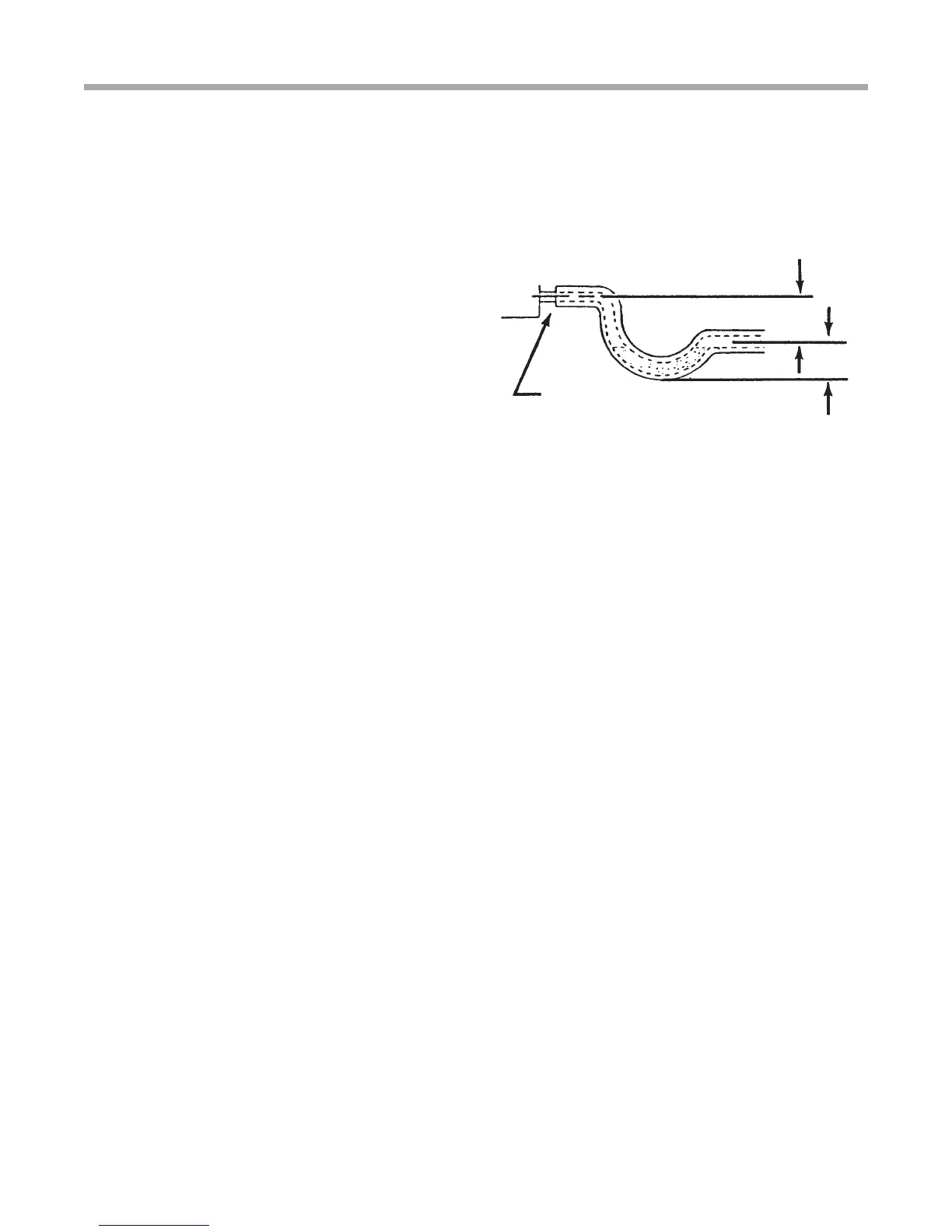

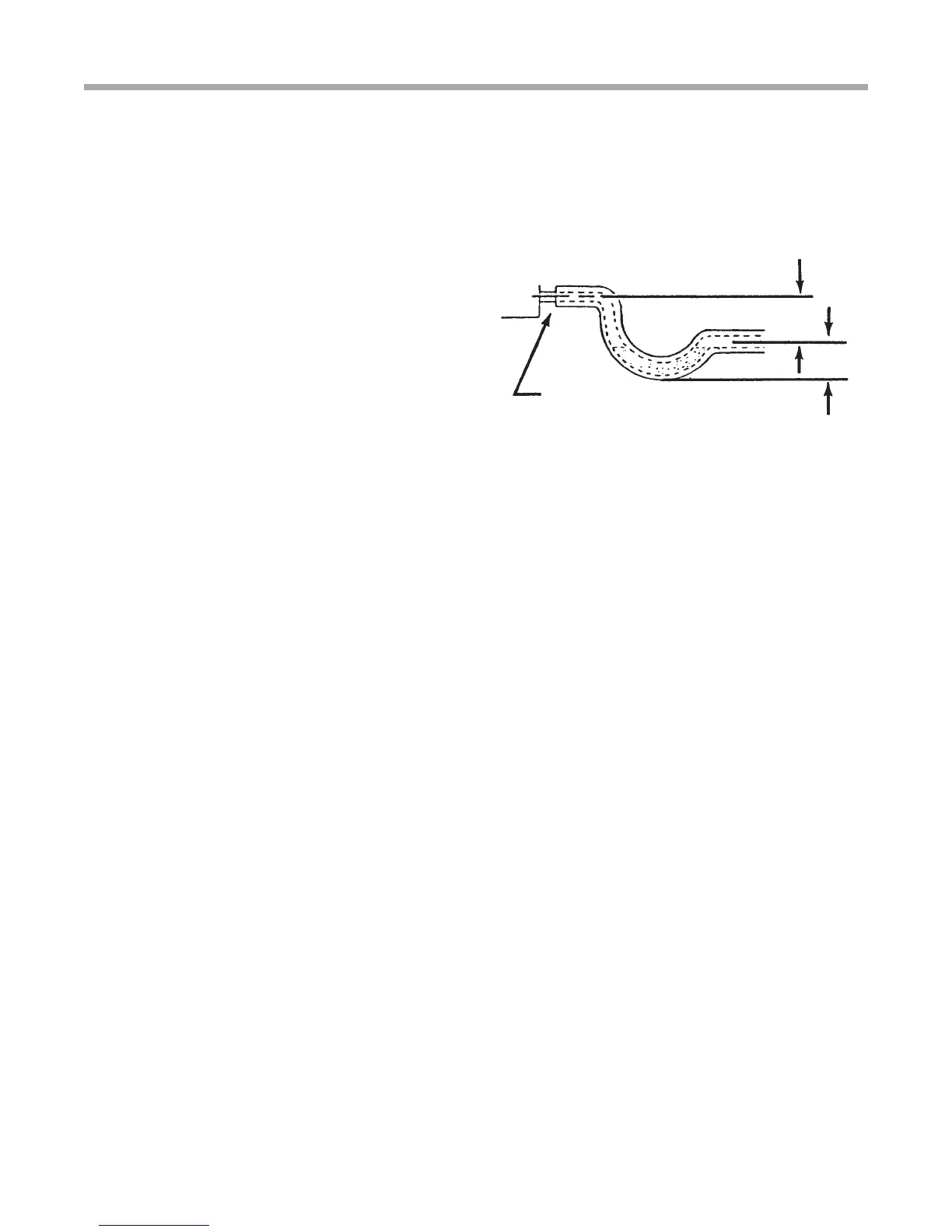

• Make sure unit is level or pitched slightly toward primary

drain connection so that water will drain completely from

the pan (See Figure 4).

• Do not reduce drain line size less than connection size

provided on condensate drain pan.

• All drain lines must be pitched downward away from the

unit a minimum of 1/8” per foot of line to ensure proper

drainage.

• Do not connect condensate drain line to a closed or

open sewer pipe. Run condensate to an open drain or

outdoors.

• The drain line should be insulated where necessary to

prevent sweating and damage due to condensate forming

on the outside surface of the line.

• Make provisions for disconnecting and cleaning of the

primary drain line should it become necessary. Install

a 3 in. trap in the primary drain line as close to the unit

as possible. Make sure that the top of the trap is below

connection to the drain pan to allow complete drainage of

pan (See Figure 4).

• Auxiliary drain line should be run to a place where it will

be noticeable if it becomes operational. Occupant should

be warned that a problem exists if water should begin

running from the auxiliary drain line.

• Plug the unused drain connection with the plugs provided

in the parts bag, using a thin layer of Tefl on paste, silicone

or Tefl on tape to form a water tight seal.

• Test condensate drain pan and drain line after installation

is complete. Pour water into drain pan, enough to fi ll

drain trap and line. Check to make sure drain pan is

draining completely, no leaks are found in drain line

fi ttings, and water is draining from the termination of the

primary drain line.

'2 127 23(5$7( 81,7 :,7+287

&21'(16$7( '5$,1 75$3

81,7 0867 %( 6/,*+7/< ,1&/,1('

72:$5' '5$,1 &211(&7,21

'2 127 29(57,*+7(1 '5$,1 ),77,1*

81,7

Installation

It is always recommended that an auxiliary drain pan be

installed under a horizontally installed air handler.

Connect the auxiliary drain line to a separate drain line (no

trap is needed in this line) and terminate according to local

codes.

NOTE: DO NOT use a torch or fl ame near the

plastic drain pan coupling.

NOTE: DO NOT tighten the drain pipe excessively.

Support the condensate piping and traps outside

the unit to prevent strain on the drain connection.

Figure 4: Condensate Drain Trap

Loading...

Loading...