39

EVH-X SPACE 2.1 - 12.1

M0SM10N17-03

Scroll compressor (only units 7.1-10.1-

12.1)

The Scroll compressors have only one rotation

direction.

In the event it is reversed, the compressor is not

immediately damaged, but increases its noise and

jeopardises pumping.

After a few minutes, the compressor blocks due to

intervention of the thermal protection.

In this case, disconnect power supply and invert 2

phases on the machine power supply.

Avoid the compressor working for a long time with

contrary rotation: more than 2-3 of these

anomalous start-ups can damage it.

To ensure the rotation direction is correct, measure

the condensation and suction pressure.

The pressures must significantly differ: upon start-

up, the suction pressure decreases whereas the

condensation one, increases.

Electrical circuit

Verify that the unit is connected to the ground

plant.

Check tightening of the conductors: the vibrations

caused by handling and transport might cause

loosing .

Feed the unit by closing the sectioning device, but

leave it on OFF.

Check the tension and line frequency values which

must be within the limits:

220/240/1/50 +/-6%

380-415/ /3/50 +N +/-6%

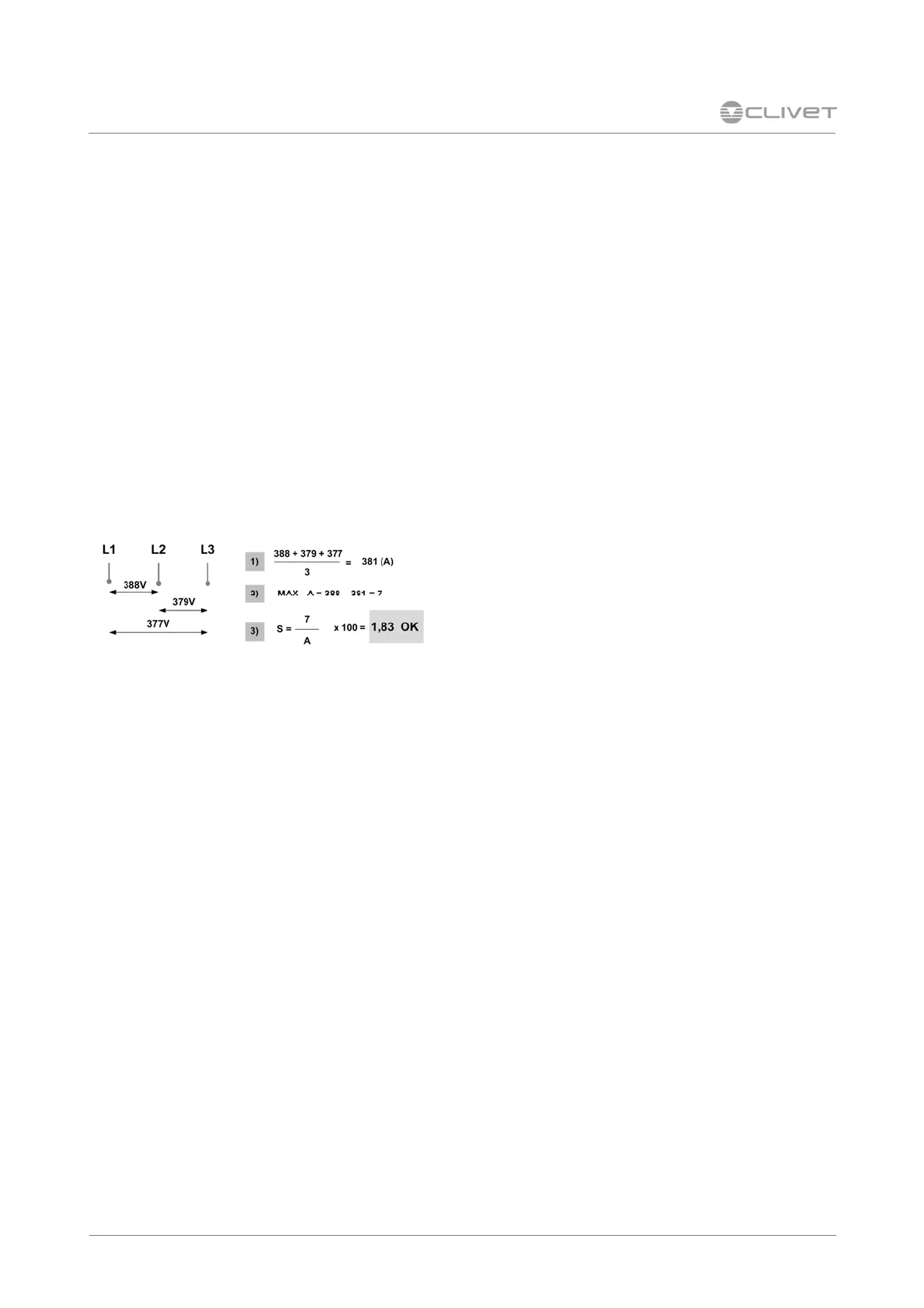

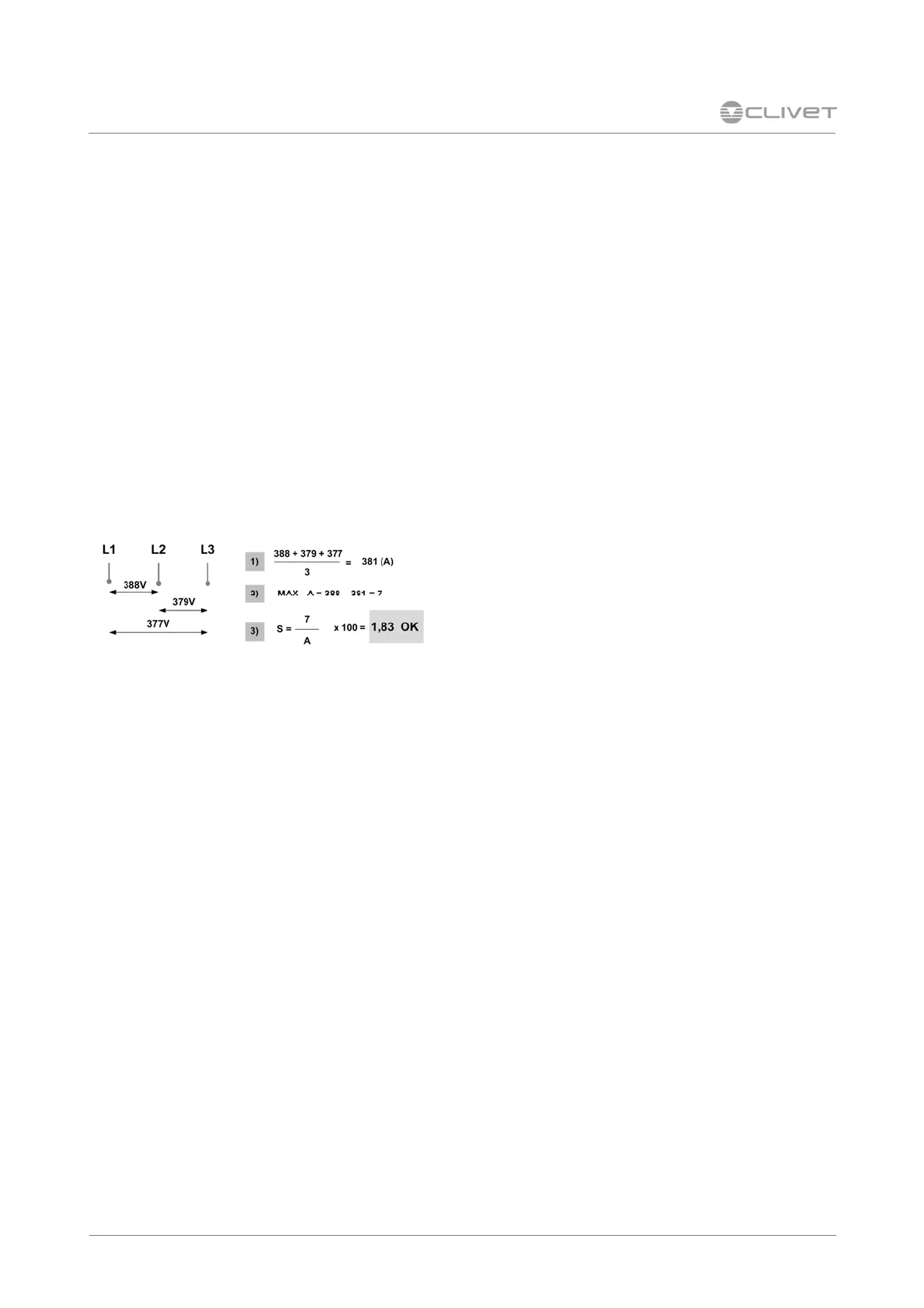

Check that the phases unbalancing must be lower

than 2%

Example:

380-415/ - 6% = 376

380-415/ + 6% = 424

The working out of the limits can cause

irreversible damages and voids the warranty.

Voltage

Check that the air and water temperatures are

included in the working limits.

Start the unit.

With unit of full load, namely in stable condions and

close to those of work, check:

• power supply tension

• total absorption of the unit

• absorption of the single electric loads

Remote controls

Check that the used remote controls (ON-OFF ecc)

are connected and, if necessary, enabled with the

respective parameters as indicated in the

“electrical connections” section.

Check that probes and optional components are

connected and enabled with the respective

parameters ("electrical connections" section and

following pages).

8 START-UP

Loading...

Loading...