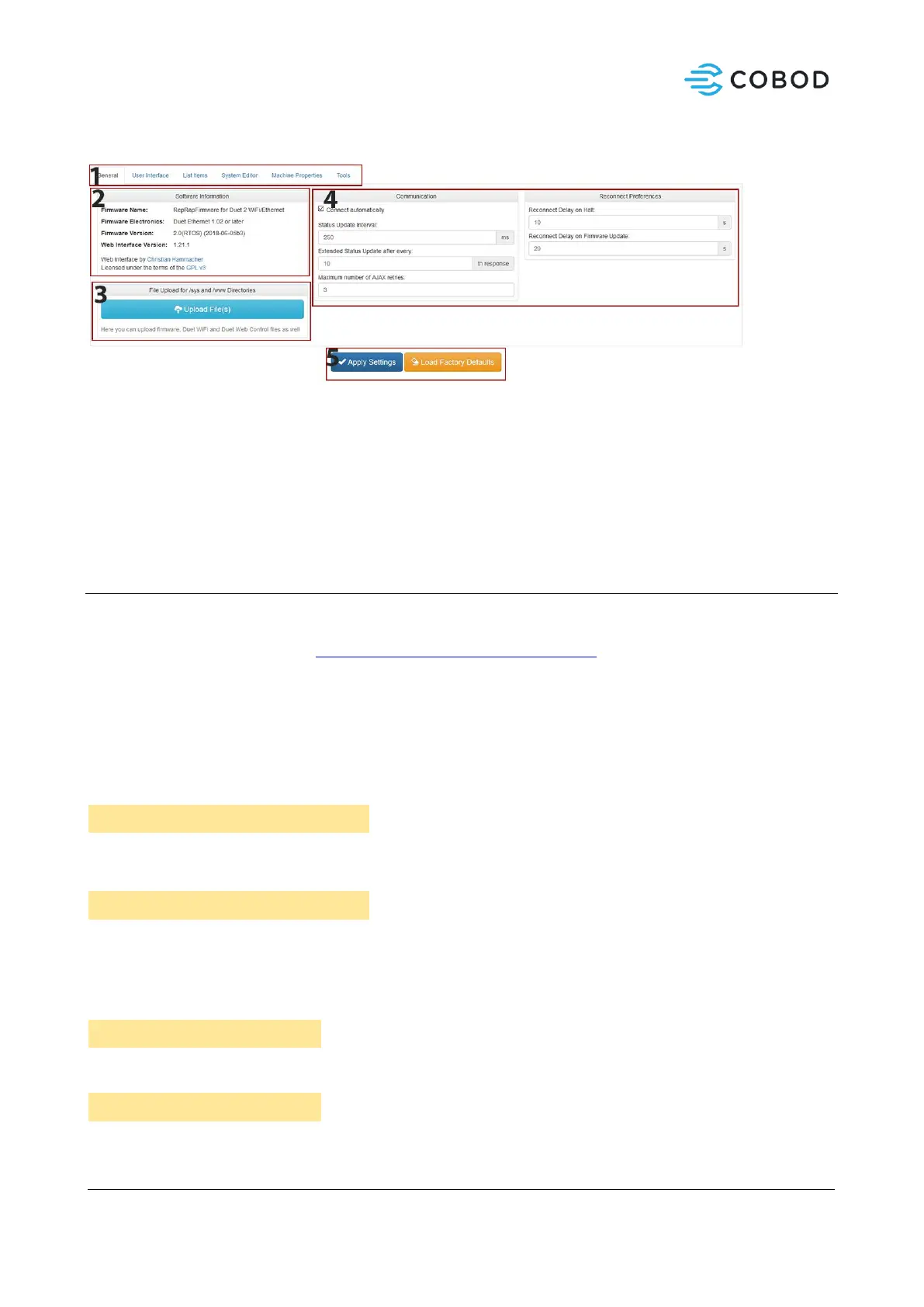

6.1.4.2.3 Settings

1. Subsetting tabs – User interface, System Editor, tools, Machine properties, List items

2. Software and firmware information

3. Button to upload firmware, control files, etc.

4. Settings related to communication and reconnecting rules.

5. Apply made changes or reset to factory Defaults.

6.1.4.3 G-code commands

G-code is the industry standard for CNC equipment, and the specific flavor of G-code for BOD2 is similar,

with some special additions. Below is a shortlist of usable G-code commands. A full G-code reference

documentation can be found at: https://duet3d.dozuki.com/Wiki/G-code.

6.1.4.3.1 Move and positioning commands

G1 Xnnn Ynnn Znnn Ennn Fnnn: Move to position Xnnx,Ynnn,Znnn while extruding Ennn amount of

material at Fnnn speed. Can be used partly or with all parameters. G0 can be used for move commands

without extrusion.

Go to Position X=400mm, Y=600mm, Z=1200mm, Extrude 150ml of material, at speed 15000 mm/min

Go to position X=400, Y=600 at default speed without extruding.

G92 Xnnn Ynnn Znnn: Set current position to Xnnn, Ynnn, Znnn. Defines the current position of the axes.

Defines current position as Origo (X=0mm, Y=0mm, Z=0mm, U=0mm)

Defines current X/Y position to be X=200 Y=200

Loading...

Loading...