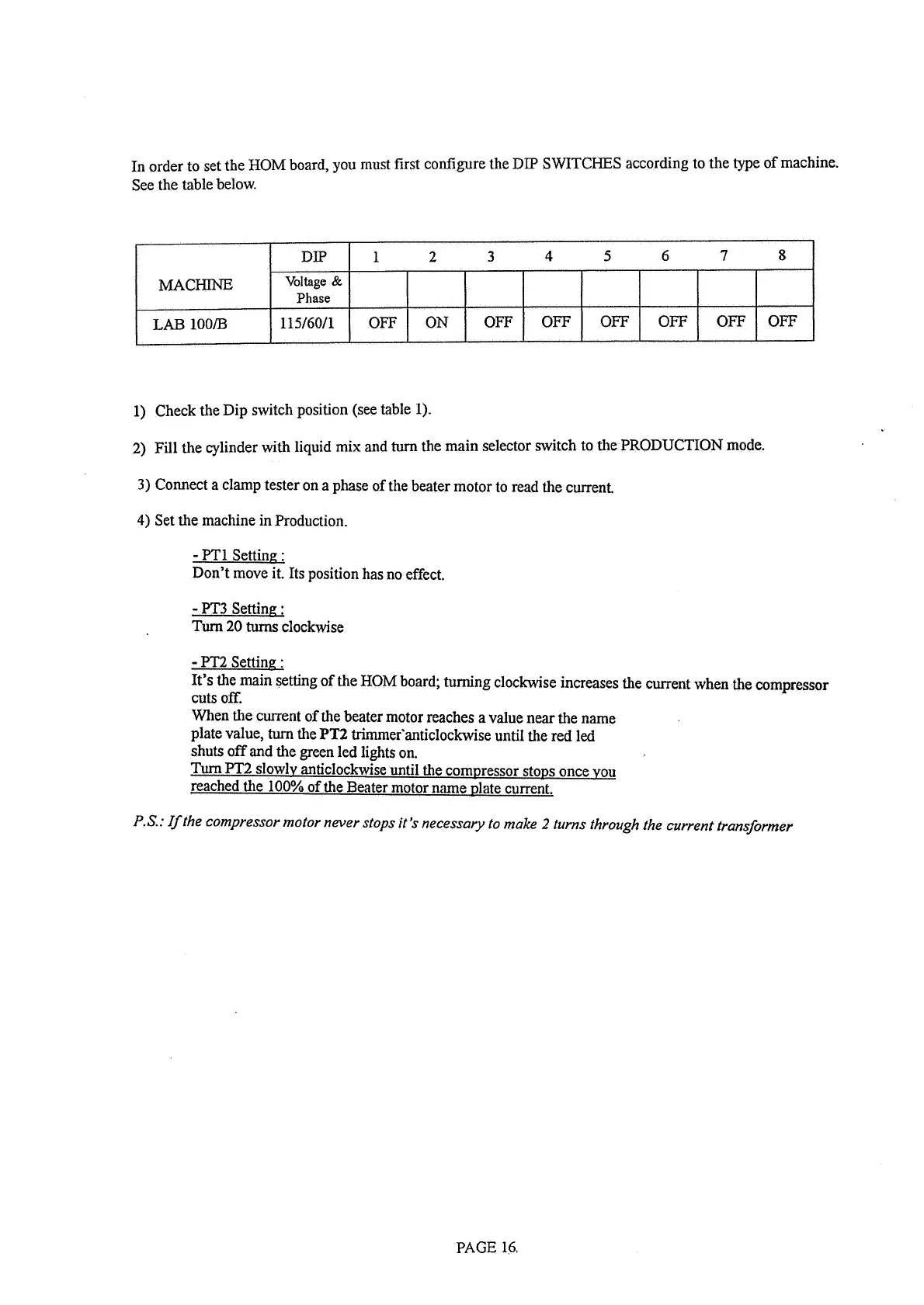

In order to set the HOM board, you must first coniigure the

DIP

SWITCHES according to the type of machine.

See the table below.

1) Check the Dip switch position (see table

1).

2)

Fill the cylinder with liquid mix and

turn

the main selector switch to the PRODUCTION mode.

3)

Connect a clamp tester on a phase of the beater motor to read the current.

MACHINE

LAB

lOO/B

4)

Set the machine in Production.

DIP

Voltage

&

Phase

115/60/1

1

2

3

4

5

6 7

8

-

PT1 Setting

:

Don't move it. Its position has no effect.

-

PT3

set tin^

:

Turn

20 turns clockwise

-

PT2 Setting

:

It's the main setting of the HOM board; turning clockwise increases the current when the compressor

cuts off.

When the current of the beater motor reaches a value near the name

plate value, turn the

PT2

trimmer'anticlockwise until the red led

shuts off and the green led lights on.

Turn

PT2

slowlv anticlockwise until the compressor stops once vou

reached the 100% of the Beater motor name plate current.

OFF OFF

P.S.:

If the compressor motor never stops it's necessary to make

2

turns through the current transformer

OFF

OFF

PAGE 16.

OFF

OFF

ON

OFF

Loading...

Loading...