Section 14: Troubleshooting 3029-014B

14-4 Concordia Integra Technical Support Manual

2900-255B

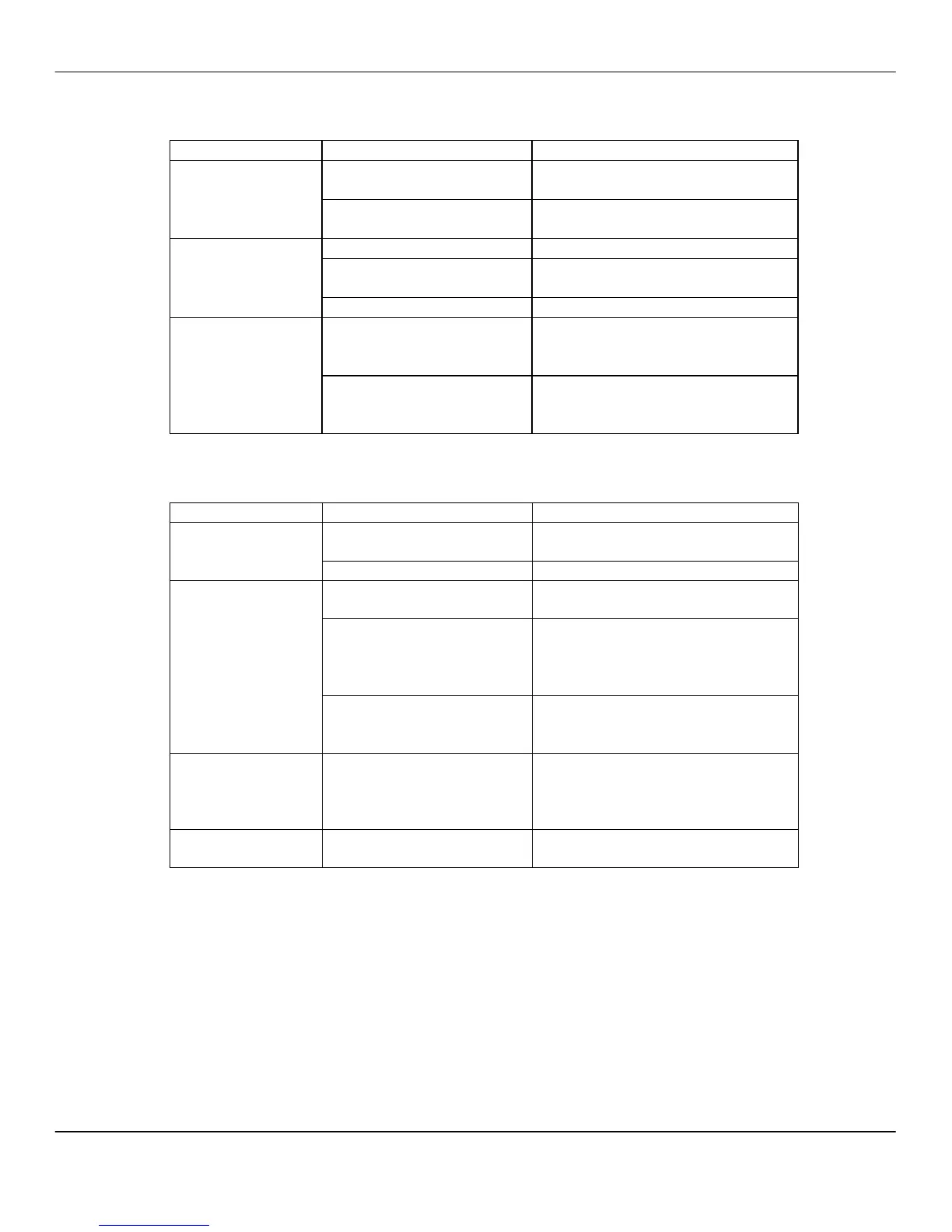

Flavor System

Air bubble(s)

in flavor tube

Check all fittings are secure

and properly connected.

Open flavor box and check to

ensure bag has no punctures.

Check flavor tube(s) for tears.

Verify fittings properly

connected.

Check flavor bag for puncture.

Incorrect placement of

flavor tubes and/or

flavor box.

Gently smooth out flavor

tube(s). Remove flavor tube,

first, if necessary.

Lift box and remove tube from

incorrect position; correctly

position flavor tube.

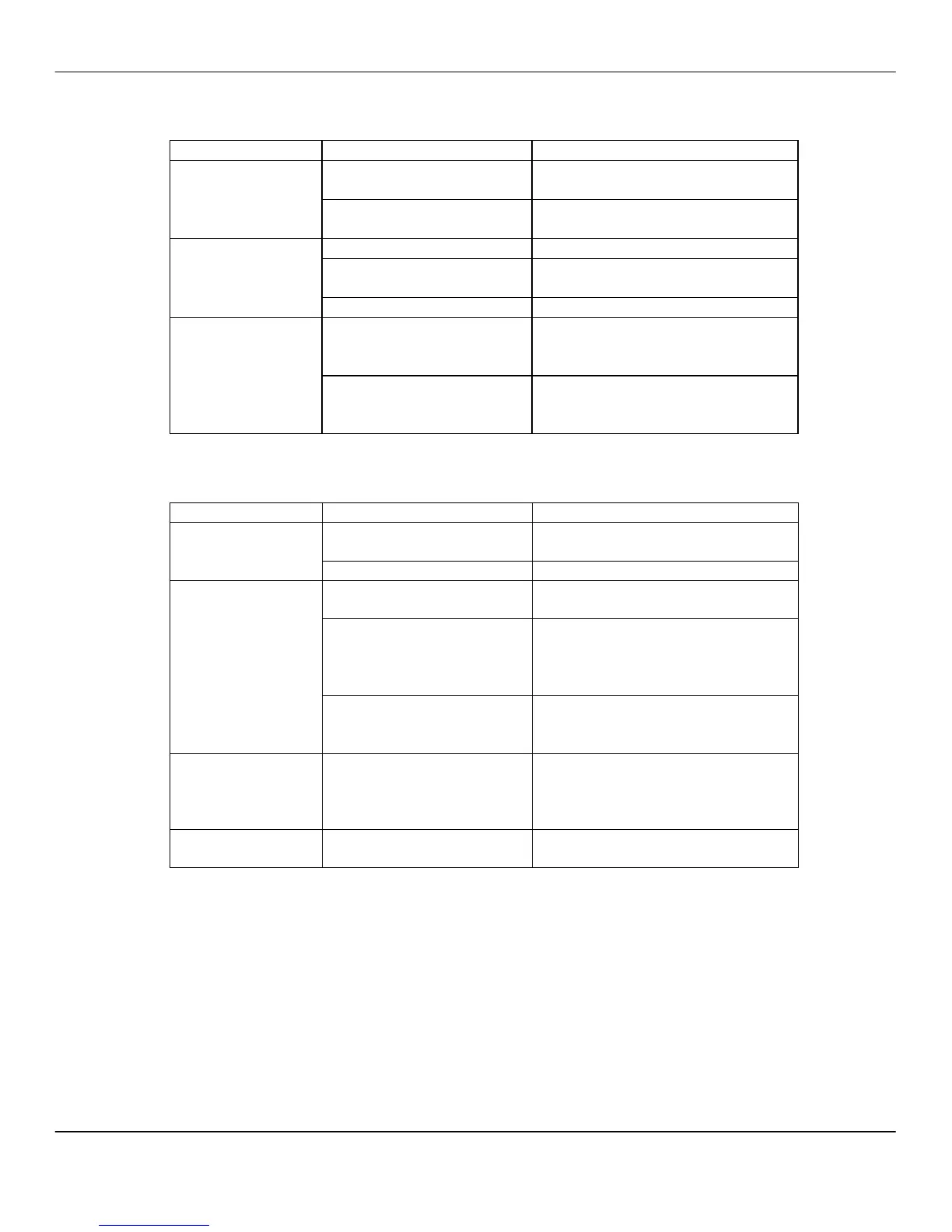

Milk System

Check steam pressure.

Check steam setting.

Milk got too warm, then

cold (shocked)

Replace milk supply with fresh

milk.

Check to verify air vent needle

is properly attached.

Verify correct air vent needle is

attached to valve.

Ensure the milk is not past its

expiration date. Restock as

necessary.

Milk spraying

during

dispensing

Dirty or clogged product

nozzle

Check for restrictions to

product nozzle.

Check for dried milk or debris

build-up in product nozzle.

Too much or

too little foam

Check air, steam, and air gate

valves.

Loading...

Loading...