4-3

4.5.4 RF Leakage Measurement

NOTE: To ensure accuracy when making leak-

age measurements, perform all leakage testing

using methods and instruments that are com-

pliant with the prcedures outlined in Section

19 of IEC60601-2-2 (Particular Requirements

for the Safety of High Frequency Surgical

Equipment).

RF Leakage can present a hazard in the operating

room because electrosurgical currents can flow

to the patient and operating room staff through

unintended paths, which can cause injury. RF

leakage occurs because the total energy in the

output voltage waveform is provided with a con-

ductive path through stray parasitic capacitance

distributed within the generator and along the

length of the leads.

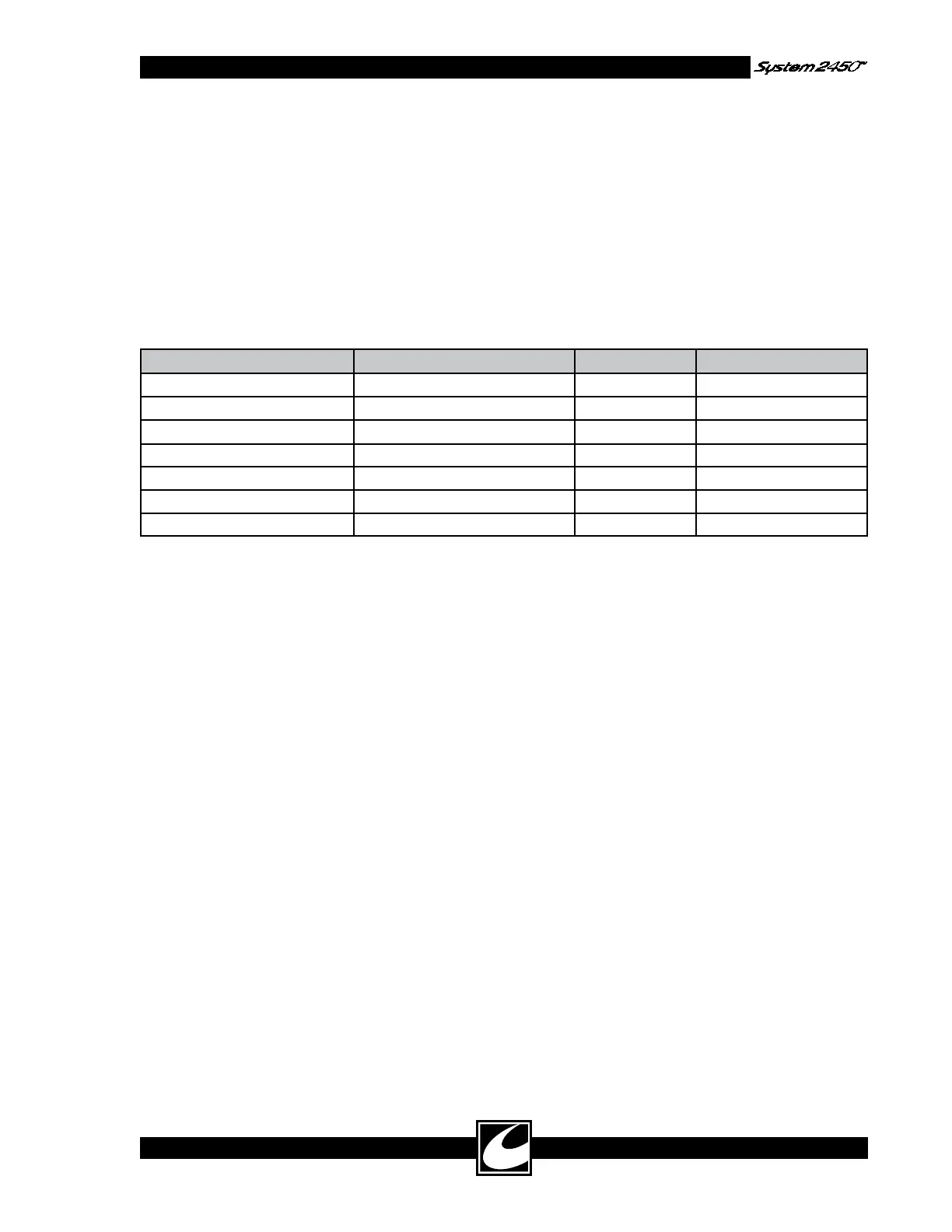

Table 4.4 presents the allowed RF leakage currents

to ground.

Table 4.4 Allowable RF Leakage Current to Ground

MEASURED TERMINAL ACTIVATED ACCESSORY MODE RF LEAKAGE (Ma)

Dispersive Electrode Coag Combination Monopolar Standard Coag < 100

Dispersive Electrode Cut Combination Monopolar Pure Cut < 100

Dispersive Electrode Hand Controlled Standard Coag < 100

Combination Monopolar Active Coag Combination Monopolar Standard Coag < 100

Hand Controlled Active Left Hand Controlled Standard Coag < 100

Bipolar Right Bipolar Footswitch Bipolar Macro < 67

Bipolar Left Bipolar Footswitch Bipolar Macro < 67

Equipment:

• ESU Tester with RF Leakage function -OR-

• 0-250 is RF Ammeter with a 200 ohm 10 W

Non-inductive Resistor

• Patient Plate Adapter Plug

• 2 - Test leads, 1 m max. Length

• 3 - Test leads, 10 cm max. Length

• Wooden table approximately 1 m from floor.

NOTE: Use a measuring device that meets IEC

specification for RMS measured over one second.

Procedure:

1) Ensure that the unit is fully assembled and all

fasteners are tight.

2) Place the ESU tester or meter with resistor on

the table so that they are at least 0.5m away

from the unit under test and any other con-

ductive surface.

3) Set the unit for full power for the modes

noted in the table. Connect the ESU tes-

ter in accordance with the manufacturer’s

instructions -OR- connect the 200-ohm non-

inductive resistor in series with the 250 mA

RF ammeter to the Equipotential Ground

Connection on the Rear Panel. Also make

sure there are no connections to any output

other than the one you are measuring.

WARNING: HAND CONTROL ACTIVA-

TIONS SHOULD BE KEYED USING

3” OR LESS WELL-INSULATED

JUMPER. USE OF AN INSULATING

ROD TO INSERT THE JUMPER IS

ADVISED TO PREVENT RF BURNS.

3) One at a time, connect test setup to each RF

output terminal indicated in Table 4.4 and

activate the unit using the corresponding

command. Confirm no meter readings exceed

the specified maximum. Hand controlled

Coag activations are accomplished by con-

necting a jumper between the left jack and

center jack of the desired hand switched acces-

sory jack.

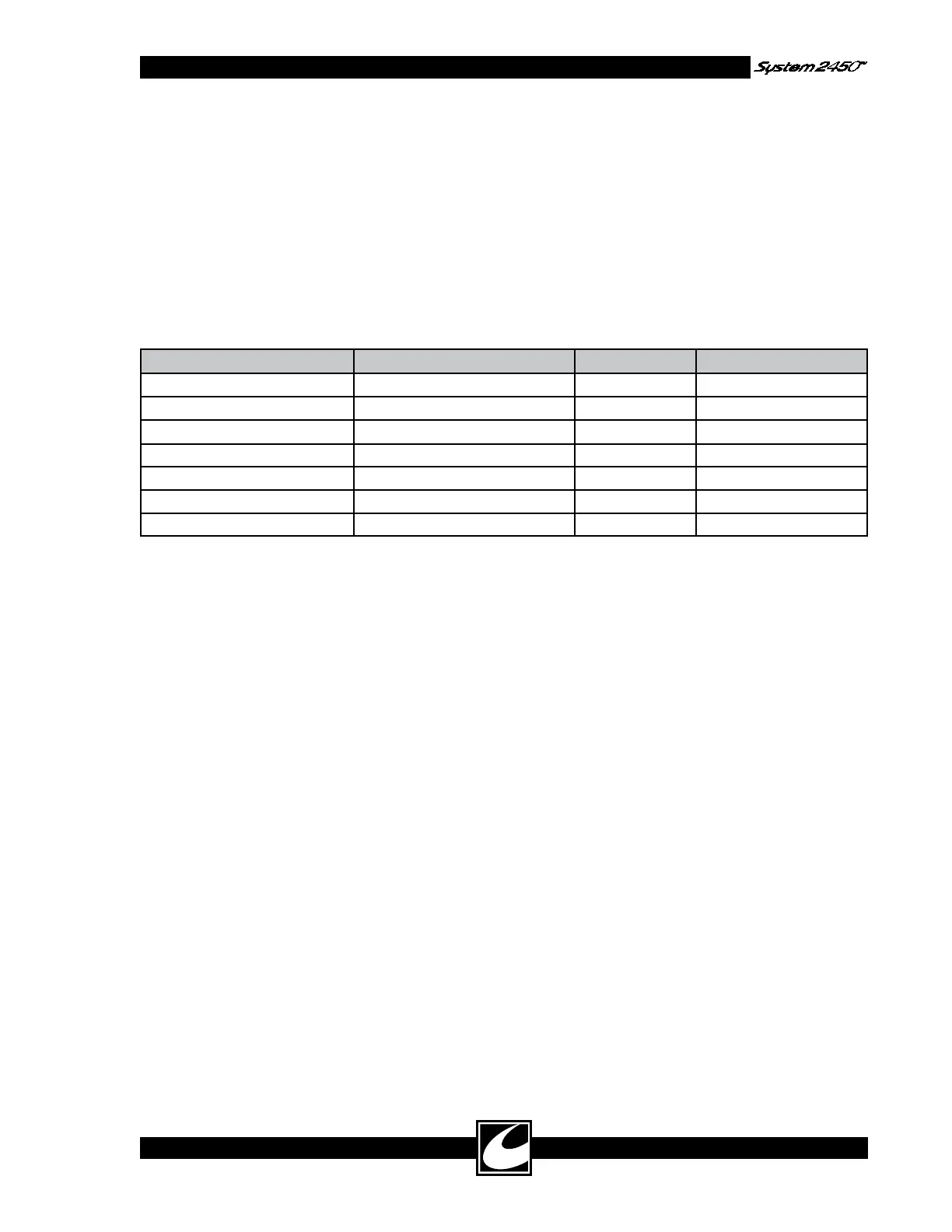

RF leakage should also be measured between inac-

tive outputs and the Dispersive Electrode connec-

tion. The procedure is as follows:

1) Set the unit for full power for the modes

noted in Table 4.5. Connect the ESU tes-

ter according to manufacturer’s instructions

- OR- the 200-ohm non-inductive resistor in

series with the 250 mA RF ammeter to the

Dispersive Electrode connection on the front

panel. Also make sure there are no connec-

tions to any output other than the one you

are measuring.

Loading...

Loading...