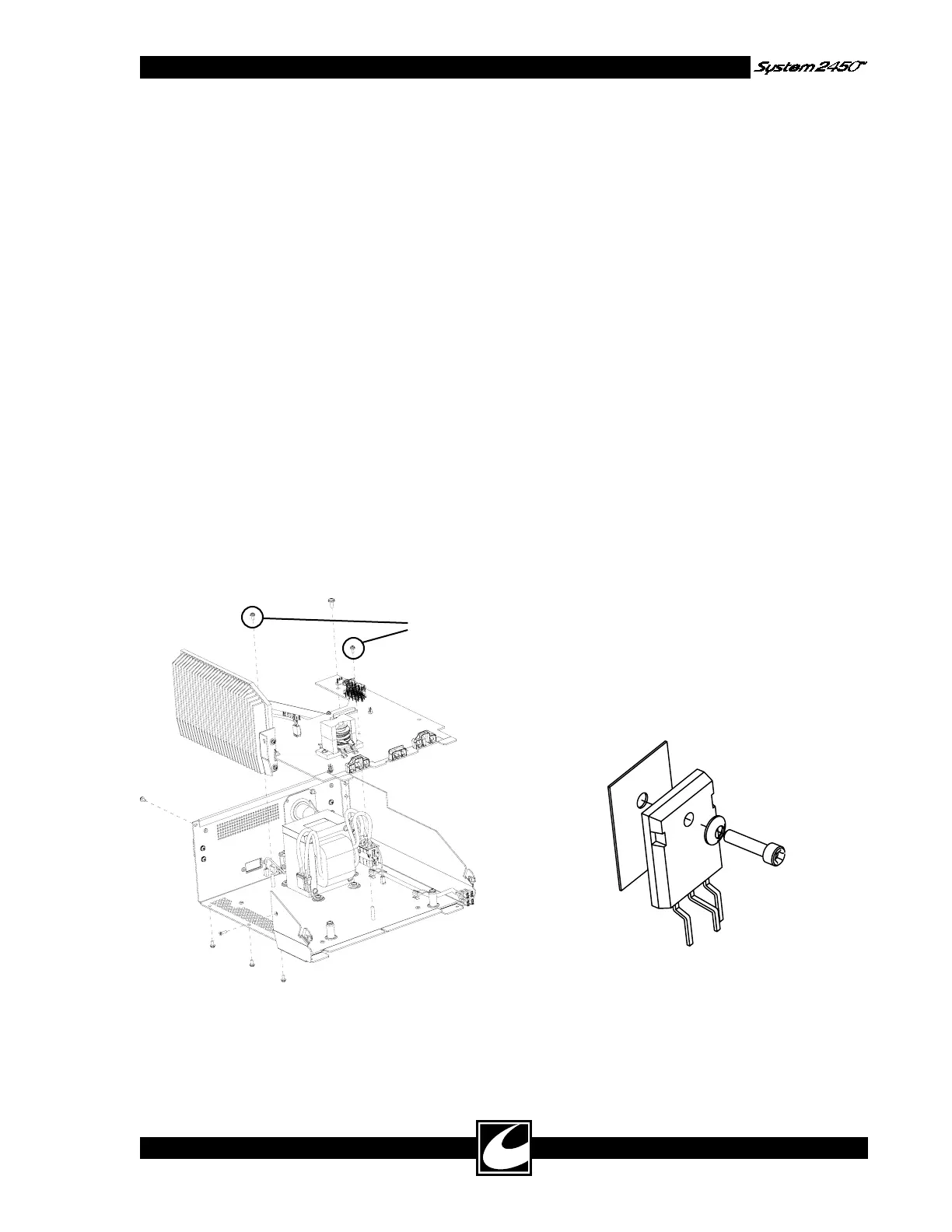

Reinstall

these two

screws first

4-17

5) Disconnect display flex connector, being care-

ful not to damage it.

Control/Display Board Replacement:

1) Connect display flex connector and place

board back onto threaded standoffs.

2) Replace aluminum standoff in its previous

location and tighten all hex standoffs.

NOTE: The aluminum standoff provides a

ground and must be located as shown below.

3) Connect ribbon cable.

4) Replace sheet metal shield and tighten six

screws into hex standoffs.

4.12.4 Power Board Removal & Replacement

Power Board Removal:

1) Remove Top.

2) Remove Bezel.

3) Remove the five screws mounted to the heat

sink in the rear, bottom and side of chassis.

4) Remove the five screws mounted to the chas-

sis standoffs. Do not remove the screws that

secure the angle bracket between the Power

PWB and the heat sink.

Power Board Replacement:

1) Reverse board removal operation.

NOTE: Install the noted two, smaller screws

first, to assure Power Board alignment in

chassis.

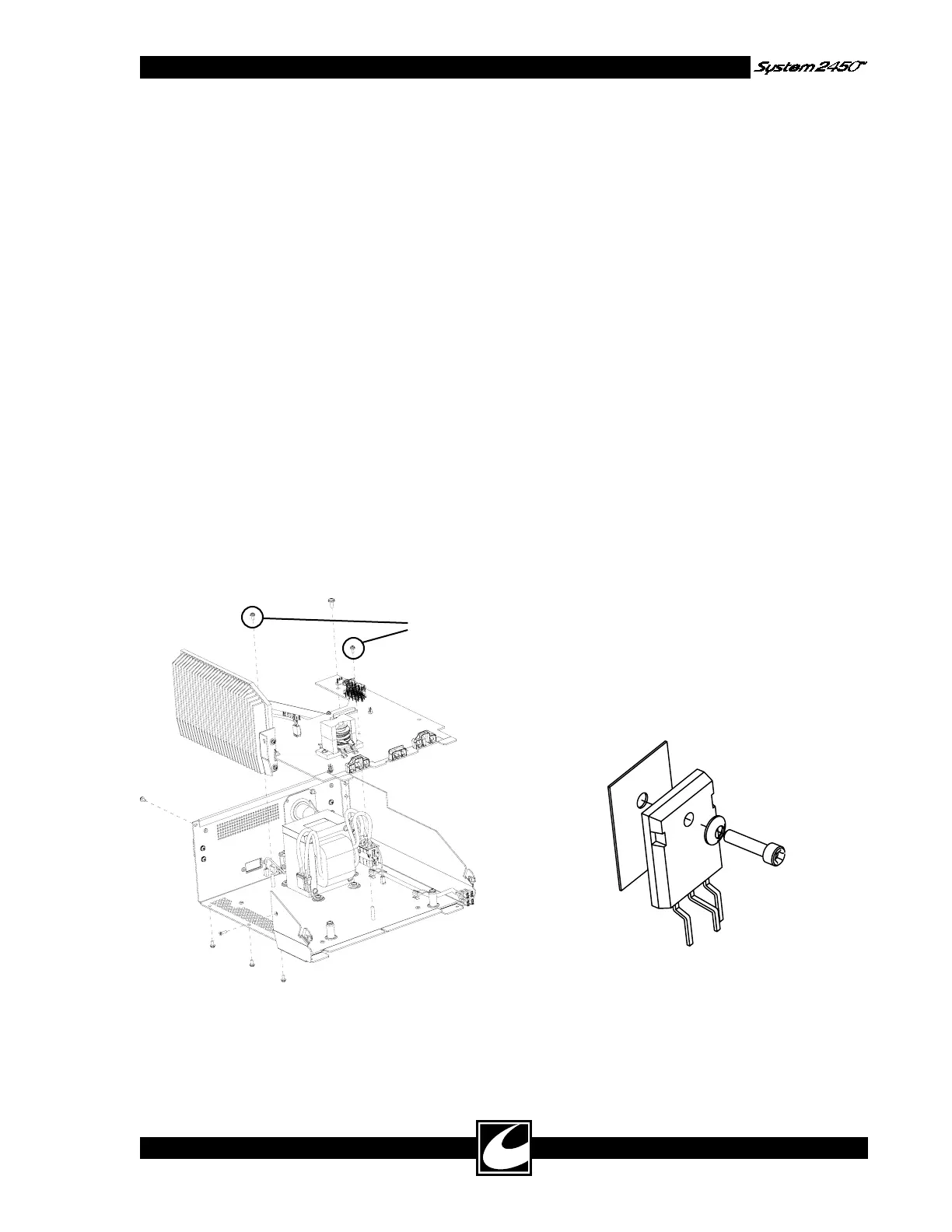

4.12.5 Power Transistor Replacement

CAUTION: This device contains components

that can be damaged by static electricity. Proper

handling by grounding of personnel during servic-

ing is mandatory.

All Power Board components mounted to the heat

sink may be replaced. Use only components sup-

plied by CONMED.

Follow these instructions for replacement:

1) No thermal compound is necessary, but the

mating surfaces of the transistor, insulator

pad and surface of heat sink should be clean.

Always replace the insulator pad associated

with the transistor. Always fasten or clamp

the part to the heat sink surface prior to sol-

dering it to the board. This will assure good

thermal contact is maintained.

2) In order to maintain alignment with the heat

sink surface, the leads of these parts have been

bent to the proper shape. They should be

purchased from CONMED with bent leads.

3) When installing these parts, be sure to orient

the Bellville washer as shown, with the convex

surface next to the head of the screw. Tighten

screws to 5-7 inch pounds.

5) Disconnect all cable connectors – Transformer,

speaker, footswitch, AC power, and 3.5mm

jack.

6) Pull board slightly forward to remove it from

the chassis.

Loading...

Loading...