Page 46

System Interface Suggestion

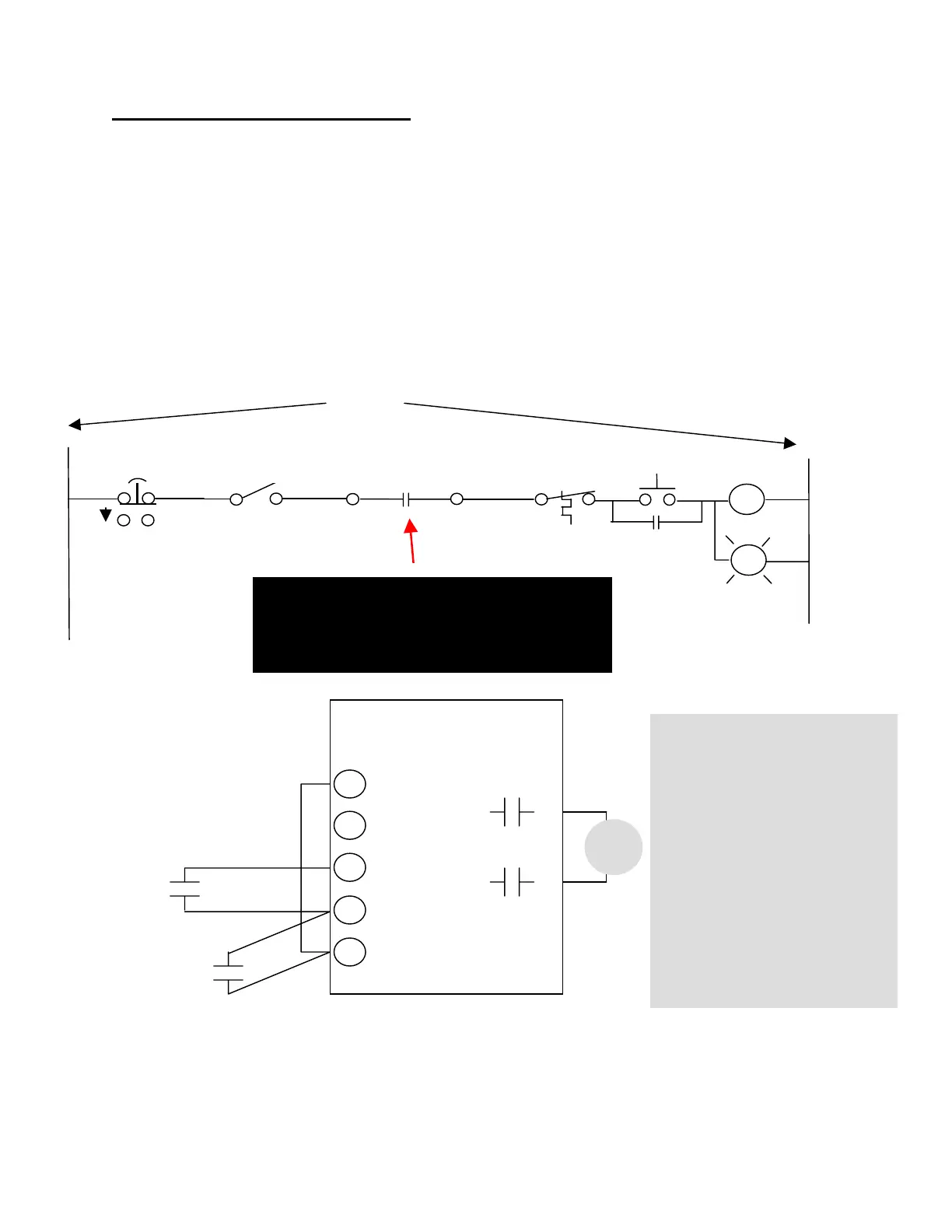

A fundamental basic system interface suggestion would be to always employ a method

to supply a “permissive” or System Enable to allow the drive system to work if all things

on the machine are alright. This interface would provide a method to keep the System

disabled if certain key safety permissives are not satisfied. The installer should

instruct, inform and warn his End User customer against bypassing the safety

permissives the Installer has provided. The System Enable function would also have

the ability to disable the drive if it was in operation and some safety device were tripped

or if the Operator encountered a need to request an Emergency Stop for instance.

The external relay logic system outlined below would provide a basic yet effective

method of supplying an overall System Enable for a Focus Drive installation.

ll other safety interlocks such as but not limited to:

Light Curtains, Overspeed or Over-Travel Limit

Switches, Safety Gates/Ropes, Two Hand palm

buttons, Jam Detection, Kill Switches etc

Emergency

Stop

Machine Ok to Run

Enable

115vac

Stays in when pressed

Pull to Reset

Keyswitch or similar

to enable machine

Motor Thermal Switch

SYSRDY

Enable Machine

System Ready

SYSRDY

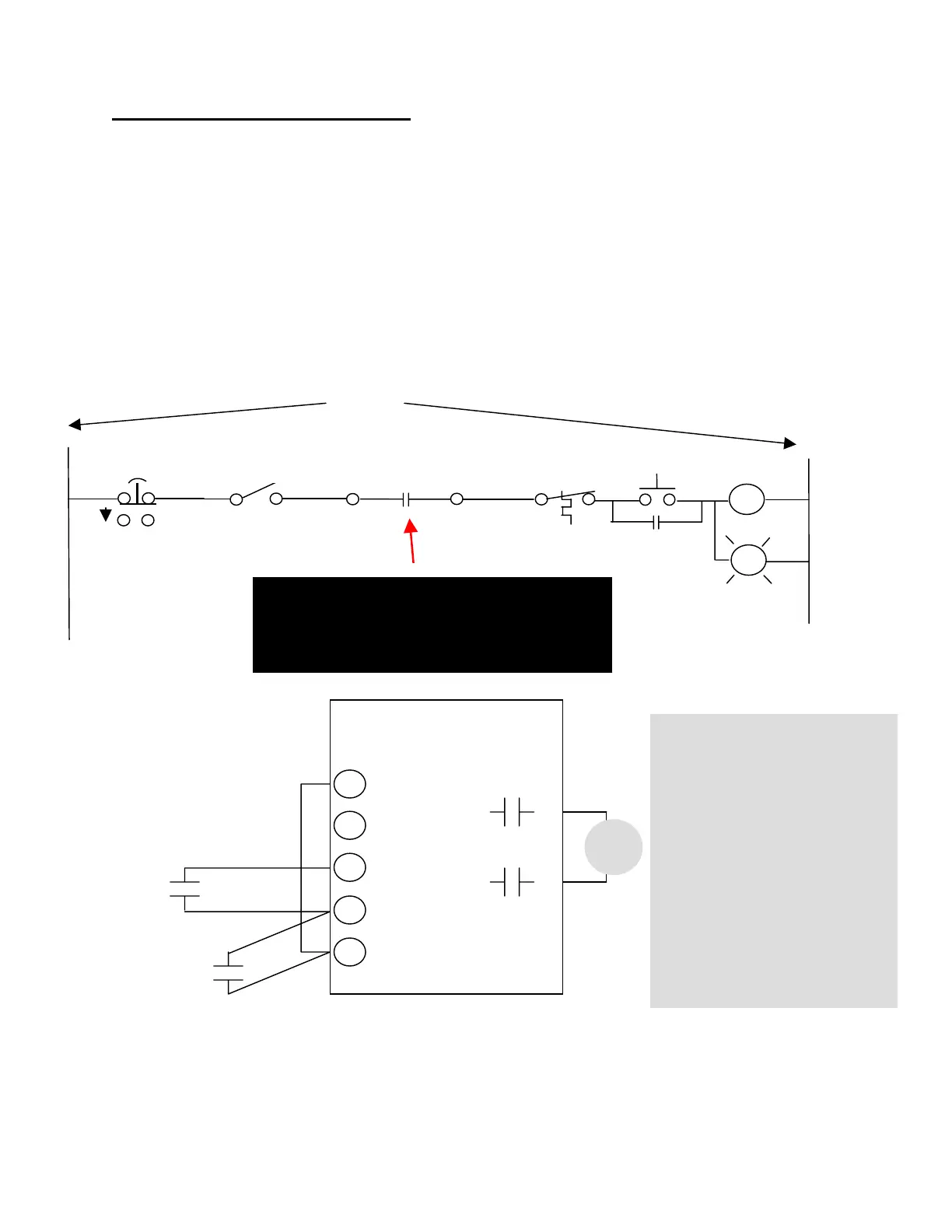

Focus 1

With Motor

Contactor Option

1

2

3

5A

5

Forward

+24vdc

N/C

Run

Remote Start

Contact

System Ready

Contact, SYSRDY

A+

A-

Power

Circuit

M

The circuit above shows the System Ready Contact being used. This contact

along with the Focus 1 Contactor option (2400-9001 kit) completely

disconnects the motor from the drive power section when the remote start and

or if the System Ready contacts open.

NOTE: Without the use of

the Contactor option, 2400-9001

(or the reversing contactor

option, 2400-9002, if reverse

is required) potential motor

movement in the event of a

power line disturbance

(causing an scr (power

device) to misfire) can occur

since the motor is connected

directly to the power circuit

even when the drive is

disabled. It is highly

recommended that one of

these contactor kits be used.

Loading...

Loading...