7 Appendix

Ethernet Option Board /

700.002 735 AE01

7-1

7 Appendix

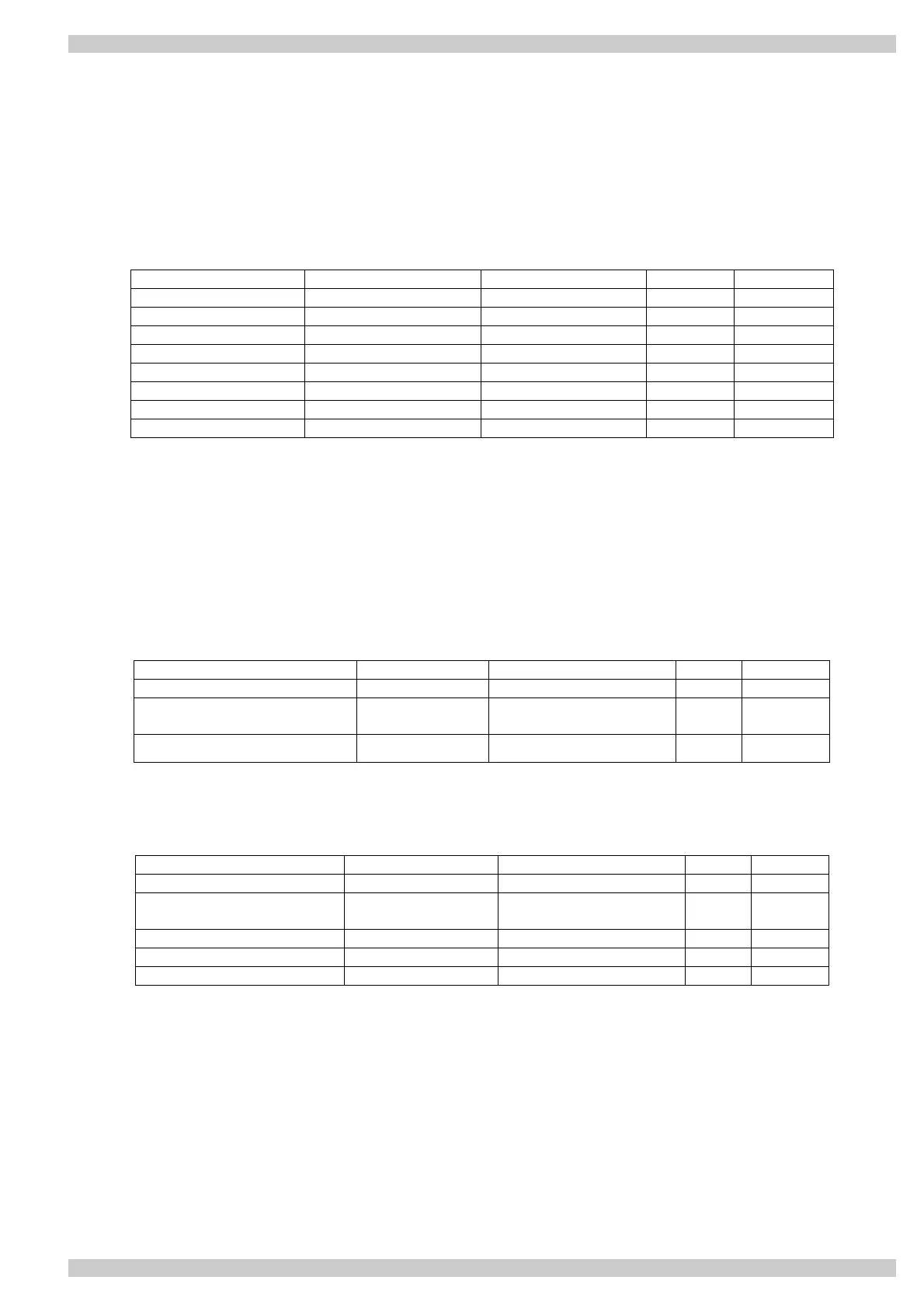

Process Data OUT (Slave to Master)

The Fieldbus Master can read the frequency converter’s actual values using process data variables.

Basic, Standard, Local/Remote Control, Multi-Step Speed Control, PID control and Pump and Fan Control

applications use process data as follows:

ID Data Value Unit Scale

2104 Process data OUT 1 Output Frequency Hz 0,01 Hz

2105 Process data OUT 2 Motor Speed rpm 1 rpm

2106 Process data OUT 3 Motor Current A 0,1 A

2107 Process data OUT 4 Motor Torque % 0,1 %

2108 Process data OUT 5 Motor Power % 0,1 %

2109 Process data OUT 6 Motor Voltage V 0,1 V

2110 Process data OUT 7 DC link voltage V 1 V

2111 Process data OUT 8 Active Fault Code - -

Table 7-1: Process data OUT variables

The Multipurpose Control application has a selector parameter for every Process Data. The monitoring values

and drive parameters can be selected using the ID number (see LV7000 All in One Application Manual,

Tables for monitoring values and parameters). Default selections are as in the table above.

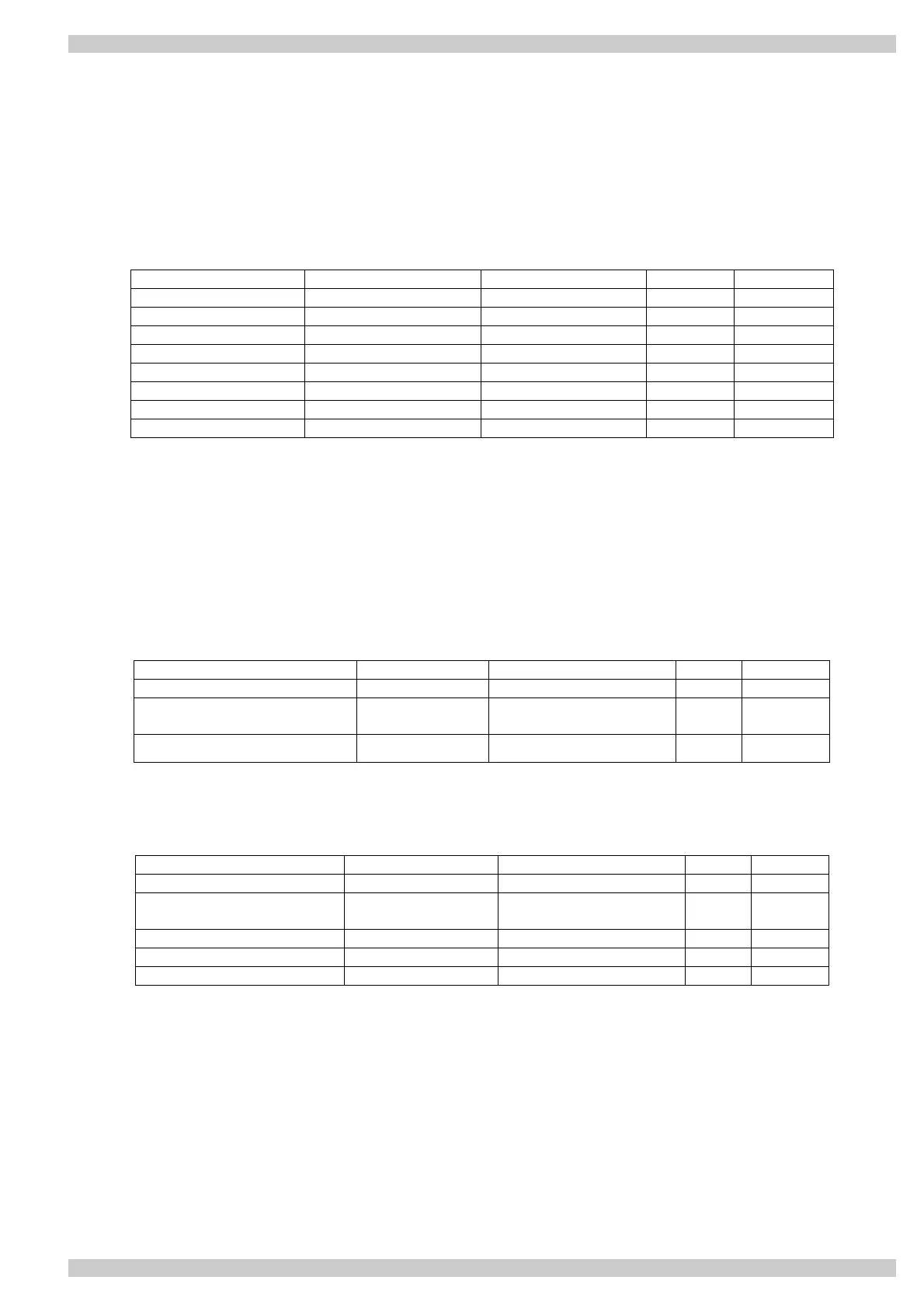

Process Data IN (Master to Slave)

Control Word, Reference and Process Data are used with all in One application as follows.

Basic, Standard, Local/Remote Control and Multi-Step Speed Control applications

ID Data Value Unit Scale

2003 Reference Speed Reference % 0.01%

2001 Control Word Start/Stop Command

Fault reset Command

- -

2004–2011 PD1 – PD8 Not used - -

Table 7-2: Process Data In (1)

Multipurpose Control application

ID Data Value Unit Scale

2003 Reference Speed Reference % 0.01%

2001 Control Word Start/Stop Command

Fault reset Command

- -

2004 Process Data IN1 Torque Reference % 0.1%

2005 Process Data IN2 Free Analogue INPUT % 0.01%

2006–2011 PD3 – PD8 Not Used - -

Table 7-3:Process Data In (2)

Loading...

Loading...