VR-32 Regulator and CL-2A Control

2-7

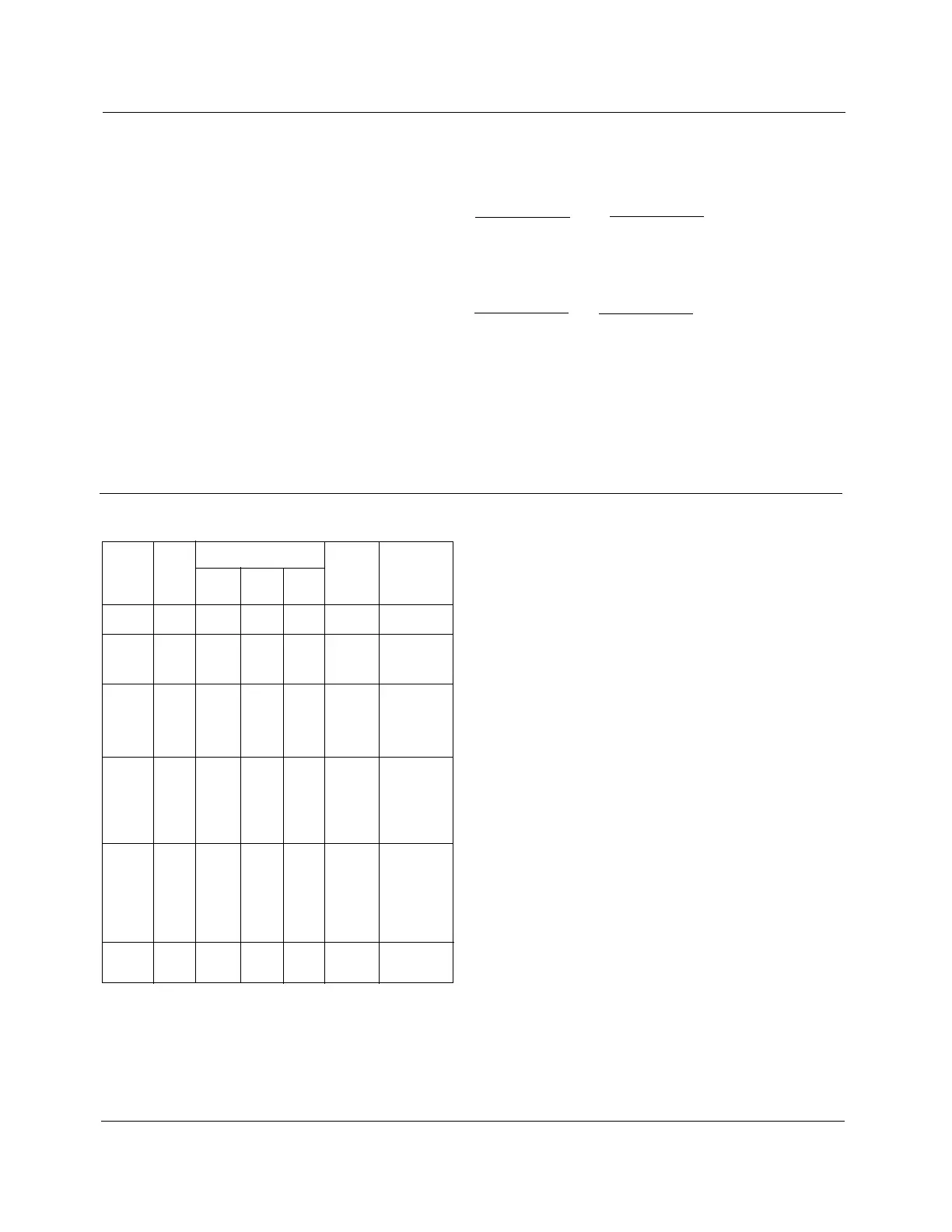

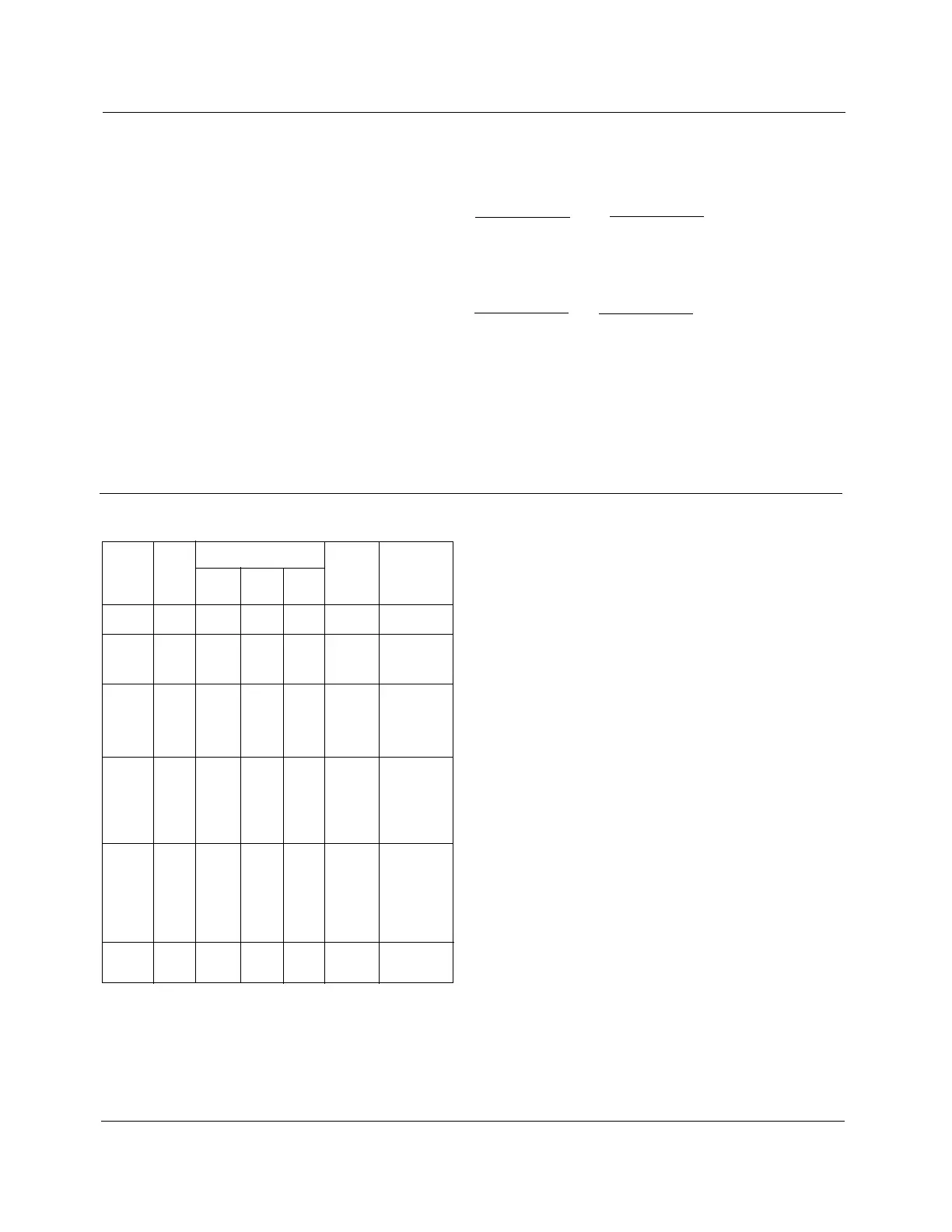

Table 2-1

VR-32 Tap Connections and Voltage Levels.

Nominal Test Overall

Regulator Single Ratio Adjusting Data Terminal Potential

Voltage Phase Internal PT RCT Voltage Ratio

Rating Voltage Tap. Ratio Tap ** **

12345 67

2500 2500

_

20:1 120 125 20:1

2400

_

120 120 20:1

5000 5000 E1/P1 40:1 120 125 40:1

4800 E1/P1 120 120 40:1

4160 E1/P1 104 120 34.7:1

2400 E2/P2 20:1 120 120 20:1

7970 E1/P1 60:1 133 120 66.5:1

7620 7620 E1/P1 127 120 63.5:1

7200 E1/P1 120 120 60:1

4800 E2/P2 40:1 120 120 40:1

4160 E2/P2 104 120 34.7:1

2400 E3/P3 20:1 120 120 20:1

13800 13800 E1/P1 115:1 120 120 115:1

13200 E1/P1 115 120 110.2:1

12000 E1/P1 104 120 99.7:1

7970 E2/P2 57.5:1 133 125 63.7:1

7620 E2/P2 133 120 63.7:1

7200 E2/P2 120 125 57.5:1

6930 E2/P2 120 120.5 57.5:1

14400 14400 E1/P1 120:1 120 120 120:1

13800 E1/P1 115 120 115:1

13200 E1/P1 110 120 110:1

12000 E1/P1 104 115 104:1

7970 E2/P2 60:1 133 120 66.5:1

7620 E2/P2 127 120 63.5:1

7200 E2/P2 120 120 60:1

6930 E2/P2 115 120.5 57.5:1

19920 19920

_

166:1 120 120 166:1

17200

_

166:1 104 120 143.9:1

To calculate the appropriate voltage setting for system voltages

other than that shown, the following formula can be used (along

with Table 2-1)

System Voltage

X

120

=

Control Voltage

Internal PT Ratio RCT Tap Voltage Setting

As an example, consider a 13800V regulator installed on a

12470V system. The calculation is:

12470

X

120

=

125 Control

115

(From Table 2-1) 104 (From Table 2-1) Voltage Setting

Utilize this setting provides regulation at

12470 volts, nominal system voltage.

Development of Potentials (Voltage Circuits)

All Cooper Power Systems VR-32 regulators have provisions

for operation at system voltages lower than the nameplate rat-

ing, as illustrated by Table 2-1. This is accomplished by pro-

viding a voltage sensing potential winding with taps which

roughly correspond to the appropriate system voltage. This

source may be either a winding on the main core/coil assem-

bly, or a separate potential transformer located on the output

(load) side of the regulator. The taps from this source are

brought to a terminal board located on top of the tap changer

assembly, under oil (see Figure 2-4). The connections are

made with push-on terminals and are easily accessed through

the handhole.

The tapped potential winding cannot always provide adjust-

ment of the voltage fine enough for control purposes. A tapped

autotransformer is therefore used for fine voltage adjustment.

This transformer is referred to as the Ratio Correcting

Transformer (RCT) and has taps at 104, 110, 115, 120, 127,

and 133 volts. It is located on the back panel in the control

enclosure (see Figure 2-5). To operate a regulator on a sys-

tem other than its rating, the appropriate selection must be

made for the internal tap, RCT tap, and control voltage set-

ting. The nameplate always provides all these values for the

common system voltages which are applicable for the rating

(see Figure 2-6).

* P taps are used with E taps only on regulators where an internal poten-

tial transformer is used in conjunction with the control winding to provide

voltage supplies to the control. See nameplate for verification of this

type of control supply.

* Test Terminal voltage and overall potential ratio may vary slightly from

one regulator to another. See the regulator nameplate for determining

the exact value

s.

Loading...

Loading...