1-8

VR-32 Regulator and CL-2A Control

3. Raise the cover assembly and attached components over

the tank. Make certain of proper orientation.

4. Lower the unit, positioning the channels in the tank guides.

Guide the control cabinet onto its brackets.

5. Seat the unit in the tank. Tighten the cover clamps or bolts

and replace the control mounting bolts.

NOTE: Tap the cover with a rubber hammer around the

edge to properly seal the gasket while tightening the cover

band.

6. Check and retighten horizontal side channel bolts through

handhole, if required.

Maintenance

The following is the recommended maintenance program for a

regulator that has been untanked:

1. Check all connections for tightness.

2. Check all contacts for wear (refer to

S225-10-2).

3. Avoid removing the main core-and-coil assembly from the

oil, except when a winding failure occurs. Blocking between

the cover and tank lip should be employed to suspend the

core-and-coil assembly within the oil until inspection of the

tap changer or other maintenance is complete.

WARNING: When the internal assembly is lifted

for inspection or maintenance, blocking should be

placed between the cover and the top of the tank to

keep the assembly from falling should lifting apparatus

fail.

!

If it is necessary to remove the main core-and-coil assembly

from the oil, the following steps should be followed.

A. The tap changer must not be subjected to temperatures

above 66

o

C. (150

o

F). It must be removed if the unit is

baked at higher temperatures.

B. If the unit is out of oil more than four hours, it must be

rebaked for a minimum of 24 hours at 100

o

C (212

o

F).

The maximum number of times a unit should be rebaked

is twice.

C. Within four hours after bake, the unit should be retanked

and filled with oil.

D. It is recommended that a vacuum be pulled on the unit

for at least one hour (2 mm. of vacuum or better) after the

unit is completely refilled with oil. If vacuum processing is

not available, allow the entire internal assembly to soak

in the oil for at least five days before energizing.

E. Do not test the unit until either the vacuum processing or

the soaking has been completed.

4. Consider upgrading controls to latest design.

CO N ST R U CTIO N

Surge Protection

SERIES SURGE ARRESTER

All VR-32 regulators are equipped with a bypass arrester con-

nected across the series winding between the source (S) and

load (L) bushings. This bypass arrester limits the voltage devel-

oped across the series winding during lightning strikes, switch-

ing surges, and line faults. The series surge arrester can be

seen in Figure 1-2. A MoV-type series surge arrester of 2.2 kV

offers series winding protection on all regulators except those

rated over 14,400 volts which have a 3/4.5-kV MoV-type series

surge arrester.

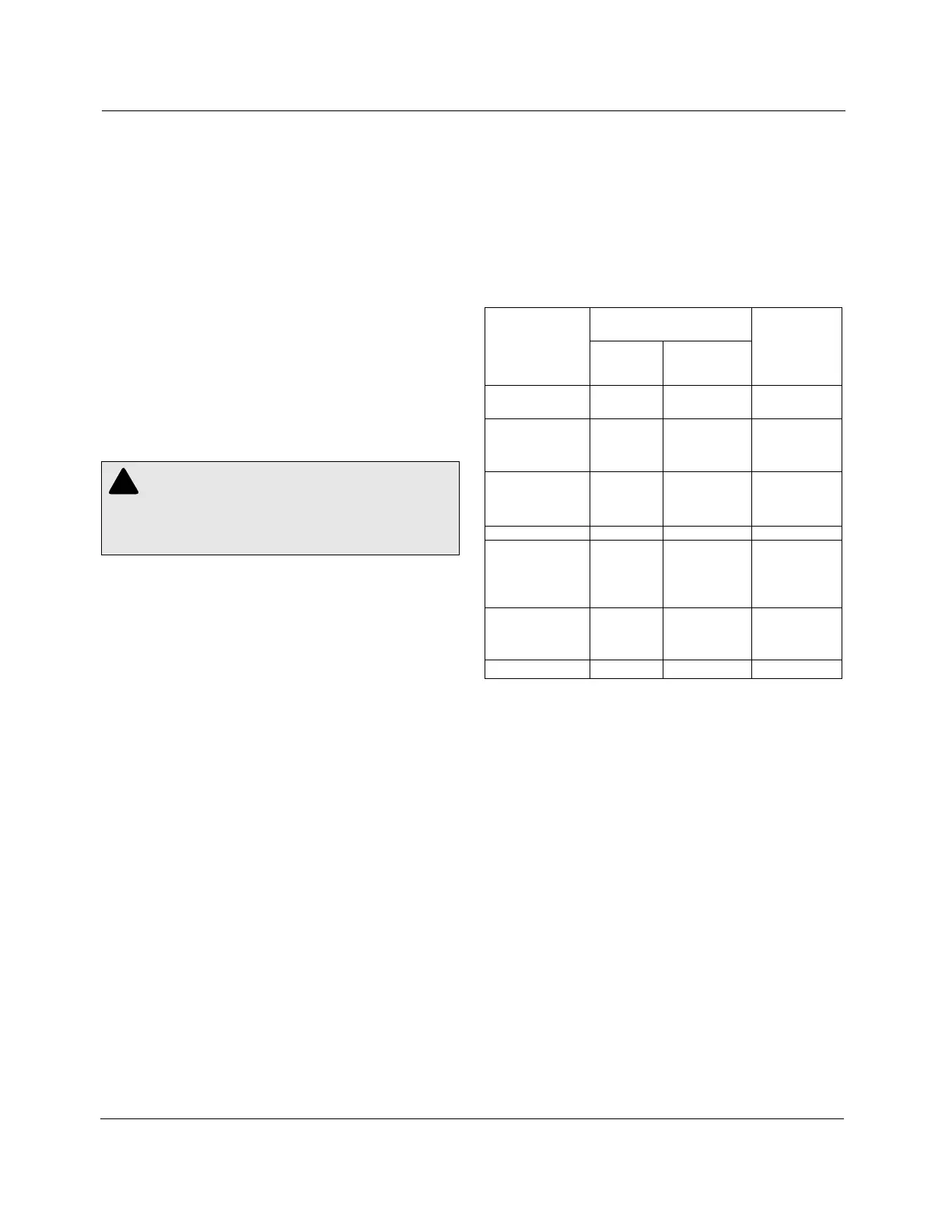

SHUNT ARRESTERS

A shunt arrester is an optional accessory on the VR-32 regula-

tor for protection of the shunt winding. The shunt arrester is a

direct connected arrester mounted on the tank and connected between

TABLE 1-1

Shunt Arrester Application Data.

the “L” bushing and ground. For additional protection a shunt

arrester may also be installed between the S (source) bushing

and ground.

For best results, locate these arresters on the mounting pads

provided on the tank near the bushing. Ground the arrester and

the regulator tank to the same ground connection using the

shortest cable possible. Shunt arrester application data is listed

in Table 1-1.

Nominal System Voltages Recommended

(volts) MOV

Regulator Shunt

Voltage Delta or Multi-Grounded Arrester

Rating Single-Phase Wye Ratings

(kV)

2500/4330Y 2400 2400/4160

2500 2500/4330 3

4160 4160/7200

5000/8660Y 4330 4330/7500

4800 4800/8320 6

5000 5000/8660

6900 6900/11950

7620/13200Y 7200 7200/12470 9

7620 7620/13200

7970

7970/13800 10

12000

12470

13800 13200 15

13800

14400

13800/23900

14400/24940Y 14400/24940 18

19920/34500GrdY 19920/34500 27

Position Indicator & ADD-AMP Capability

The position indicator (Figure 1-8) is mounted on a junction box

on the cover of the regulator and is directly connected to the tap

changer by a flexible drive shaft passing through the junction

box and terminal board via a sealing gland.

The indicator face is graduated in steps, numbered 1 through

16, on each side of zero, which designates neutral. Drag hands

indicate the maximum and minimum positions attained during

raise and lower operations. The drag hands are automatically

reset around the position indicator hand by operating the drag

hand reset switch on the control front panel.

The ADD-AMP feature of VR-32 regulators allows increased

current capacity by reducing the regulation range. This is

accomplished by setting limit switches in the position indicator

to prevent the tap changer from traveling beyond a set position

in either raise or lower directions. The limit switches have

scales graduated in % regulation, and are adjustable to specific

values of 5, 6-1/4, 7-1/2, 8-3/4, and 10% regulation to alter the

regulation range. The five possible load current ratings associ-

ated with the reduced regulation ranges are summarized in

Table 1-2. At each setting a detent stop provides positive

adjustment. Settings other than those with stops are not recom-

mended. The raise and lower limits need not be the same

value.

Loading...

Loading...