VR-32 Regulator and CL-2A Control

2-11

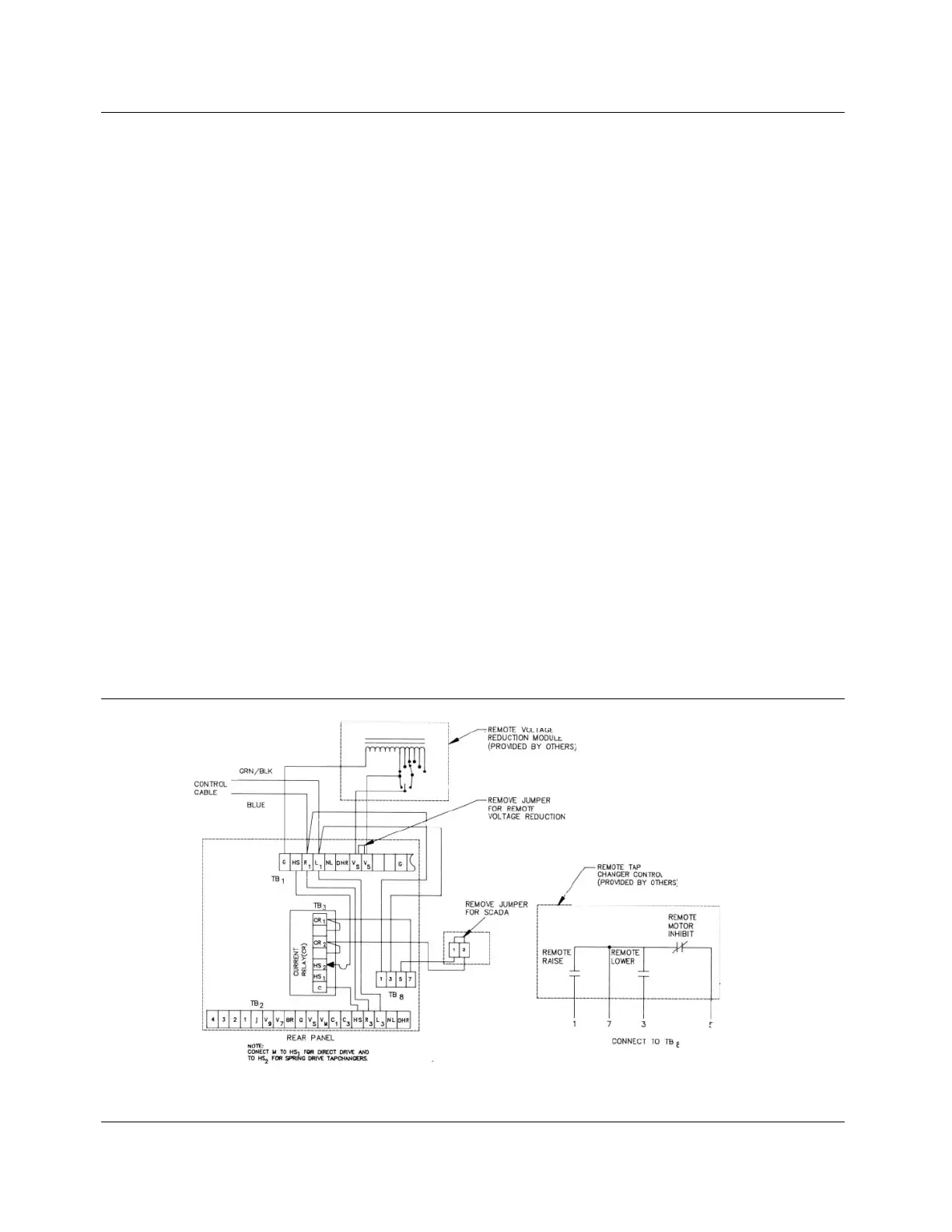

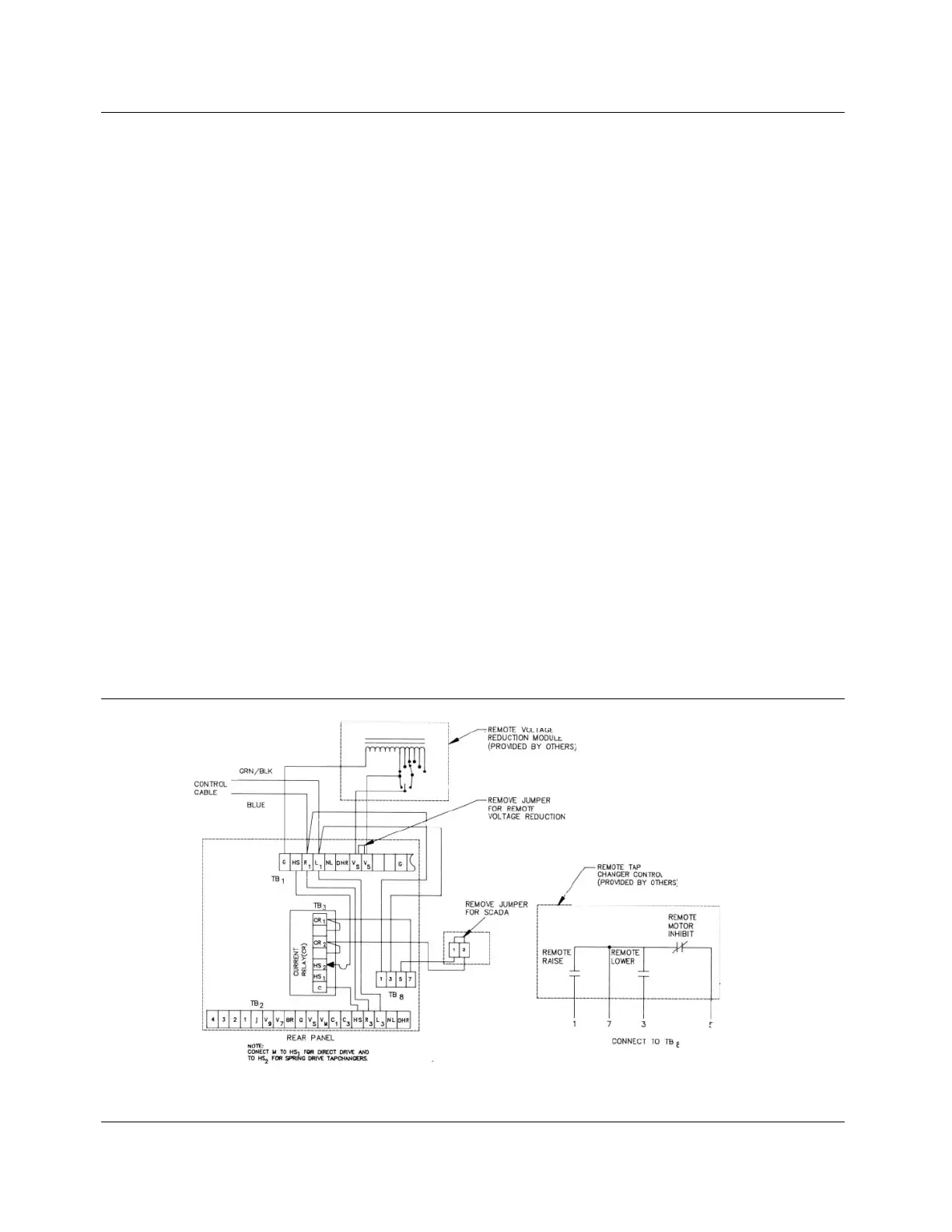

Figure 2-7.

SCADA connections to CL-2A control.

This section applies to regulator SCADA applications that

have seen increased use on distribution systems. Cooper

Power Systems has prepared a connection scheme to accom-

modate various functions while at the same time protecting the

equipment. This scheme accommodates the following func-

tions:

1. Remotely raise and lower the tap changer

2. Remotely block automatic operation

3. Remotely apply voltage reduction

The basic requirement of the scheme is the use of the cur-

rent relay package. The purpose of the current relay package

is to prevent misapplication of any SCADA system, and to

work with the holding switch to make sure a tap change is

completed once it is started. The scheme uses a current relay

to sense when the holding switch is closed. Once the holding

switch is closed, the current relay contacts open and prevent

any further power from being applied to the motor except

through the holding switch. When the holding switch opens,

the current relay contacts close, returning control of the tap

changer to one of the operational methods of control: AUTO,

MANUAL, or SCADA.

Figure 2-7 shows the basic scheme and the function of the

current relay. This general scheme applies to all Cooper

Power Systems CL regulator controls, but the wiring changes

necessary to achieve the scheme differ with the different con-

trols. The blocking (motor inhibiting) contact, shown in Figure

2-8 inhibits automatic operation of the regulator when the

SCADA scheme is in operation.

VOLTAGE REDUCTION

The use of voltage reduction is common with SCADA

schemes. Figure 2-9, shows a typical voltage reduction

method. The input voltage to the control is applied between

V(in) and common. The output voltage V(out) to common is

applied to the sensing circuit. If relay K is energized, V(out) is

greater than V(in) and when this increased voltage is applied,

he sensing circuit causes the control to lower the voltage by the

amount of increase. Various levels of voltage reduction may be

selected, depending upon the number and value of each tap on

the auto-transformer. The total range is usually 0 to 10%.

NOTE: This discussion assumes that the Cooper Power Systems

voltage reduction accessory is not being used, and SCADA

equipment is being connected directly to the bare CL-2A Control.

Refer to Figure 2-9 for proper connections. This method of volt-

age reduction is not recommended if a metering device such as

the Cooper Power System's Meter-Pac is used.

RETROFITTING A CL-2A CONTROL TO

PREVIOUS REGULATOR DESIGNS

Most Cooper Power Systems VR-32 voltage regulators produced

since 1957 can be upgraded to work with the CL-2A control. This

does not include simplified regulators (SR-32 or Auto-Boosters

®

).

This does include the line material control (1957-1963) in the

RS13Y series, the Kyle control (1963-69) in the RS83Y series,

the Canonsburg control (1969-77) in the TAB142045 or B843449

series and the CL-1 control (1977-82).

Earlier pole-star types, built in Canonsburg, cannot be

retrofitted using these instructions. The following applies to pre-

CL-1 design regulators:

A complete CL-2A control (part code #6070) must be retrofit to

the older regulator. This includes the cabinet, back panel and

front panel. The original control cable should be reused where

possible to simplify rewiring. If this is impossible, the factory

should be contacted for additional instructions. Note that all con-

trol accessories can be utilized with the retrofit CL-2A, providing

increased versatility of the regulator.

Loading...

Loading...