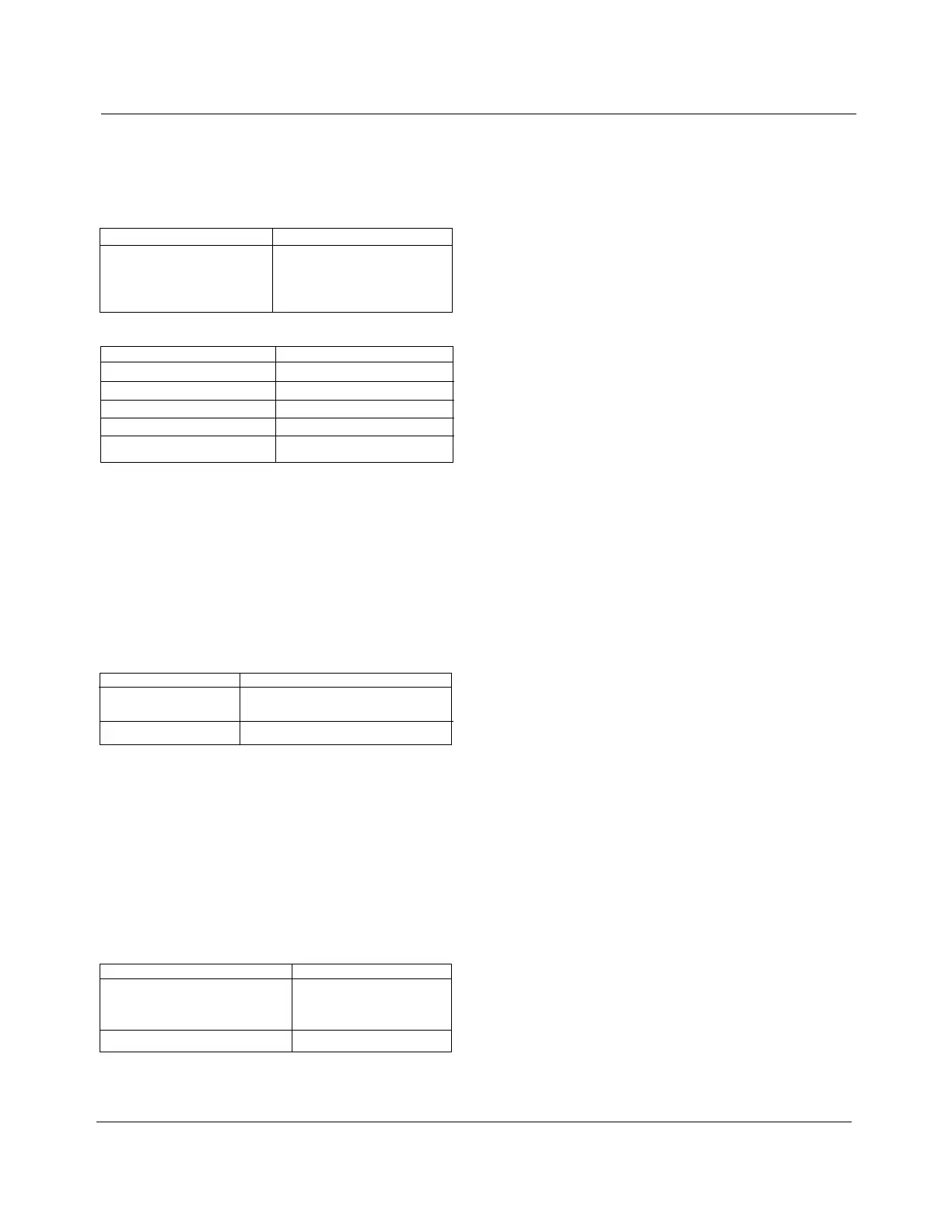

Condition Probable Fault

TP

1

Low D

5

, D

6

, D

7

, D

8

TP

2

Off R

g

, IC

3

, C

4

or lC

1

TP

3

Off IC

8

, D

1

, IC

5

or lC

1

TP

4

Off R6, Z

2

, C

11

or IC

4

TP

3

and TP

4

Low D

2

, D

3

, C

18

, lC

8

VR-32 Regulator and CL-2A Control

4-9

Now, with the input voltage set at nominal (in band), the fol-

lowing power supply voltages should be obtained between the

specified test point and TP

0

:

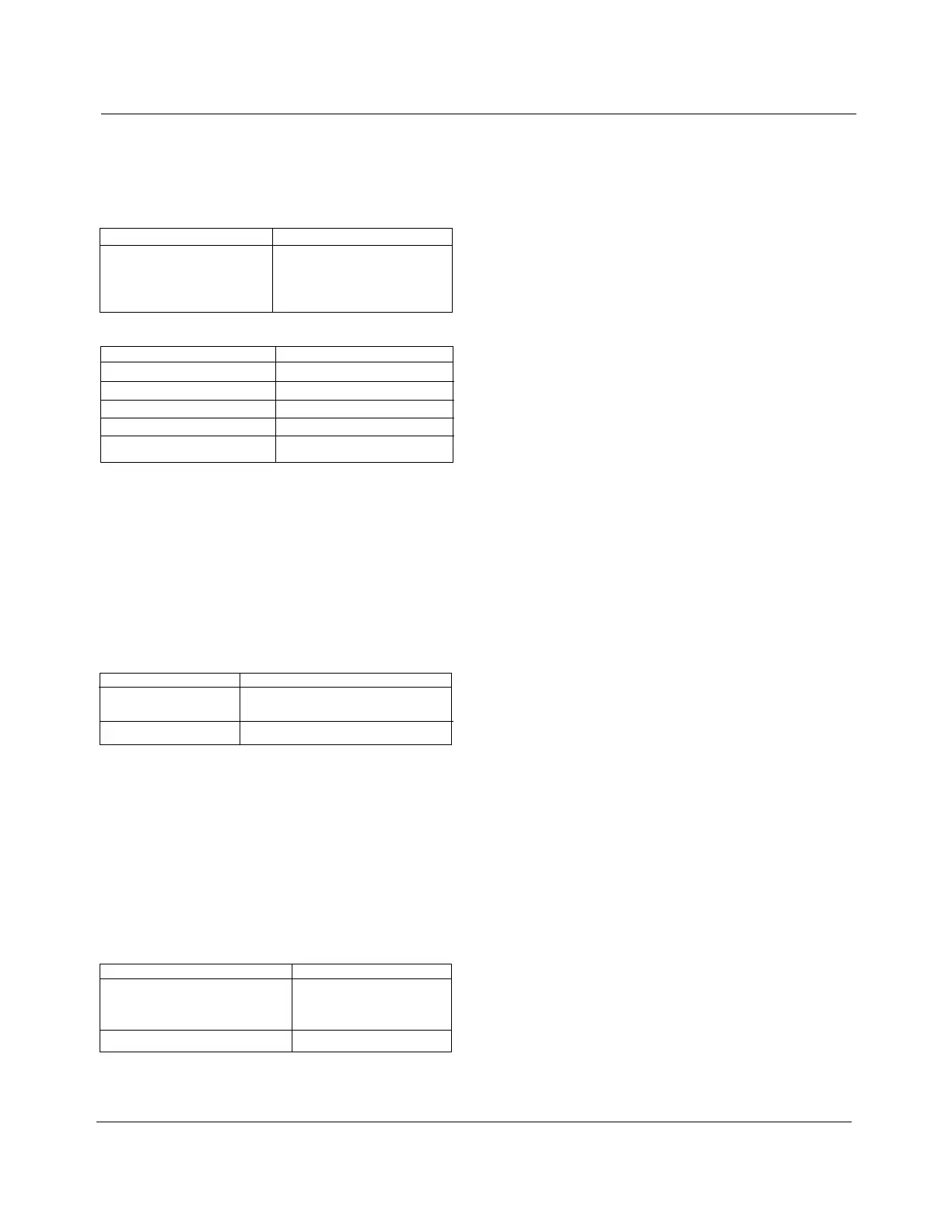

Table 4-1

Power Supply Voltages at Test Points

Failure to Conform #1

Failure to Conform #2

Failure to Conform #3

Test Point Volts dc

TP

1

+28 ± 15%

TP

2

+5.0 ± 2%

TP

3

+5.0 ± 5%

TP

4

+7.0 ± 10%

If all power supply voltages are correct, each circuit generating

an input to the microcomputer should be checked by taking

the following steps:

CHECK NO. 2 - INPUT AND FILTERING

1. Connect the multimeter to test points TP

0

and TP

5

.

2. Measure 2.5 volts dc ± 5% at TP

5

.

3. Connect an ac coupled meter having a 200 millivolt range to

test points TP

0

and TP

5

. The reading should be less than

100 millivolts.

Condition Probable Fault

DC Voltage Off Any components up to TPs in

the input section

AC Ripple High D

9

, D

10

, D

11

, D

12

, C

22

, C

3

CHECK NO. 3 - DIFFERENTIAL AMPLIFIER

1. Connect the multimeter to test points TP

0

to TP

6

.

2. Adjust the input supply until the reading at TP

6

is 2.5 volts

dc. The input should be 60 volts ac or 120 volts ac ±5%,

depending upon the board being out of or in the control,

respectively.

3. Switch the multimeter to ac and read less than 20 millivolts.

4. Switch back to dc.

5. Vary the input and read a 0.625-volt change at TP

6

for

each 2.0-volts ac change in the input related to the 120

volts ac input supply.

Condition Probable Fault

Input supply out of tolerance for R

17

, R

18

, C

6

, or IC

4

2.5 volts ac at TP

6

or ac ripple

high

Output swing to input swing Off R

19

, R

17

, R

18

, R

20

or IC

4

CHECK NO. 4 - MOTOR CURRENT SENSE

To test the motor current sensing circuitry of the circuit board,

approximately .120 amps of current must be applied to the

CURRENT SENSE input (terminals 1 & 2). This is accomplished

as follows:

1. First connect the multimeter from TP

0

to TP

7

, set for DC volts of

a scale to read up to 5.0 volts.

2. With the board in the control, connect a 1000-ohm, 20-watt resis-

tor momentarily from G to HS, on the fanning strip which leads

to the back panel. The control should be powered externally with

a 120 volt supply, attached to the EXTERNAL SOURCE termi-

nals.

3. With the board out of the control, the same resistance can be

used in series with a 120-volt ac supply, applied to the motor cur-

rent sense terminals of the circuit board.

4. For either case, with the current applied, at least 1.5 volts should

be measured. With the current removed, less than 0.4 volts

should be measured. Failure to conform can involve any compo-

nent in the motor current sense circuit.

CHECK NO. 5 - BANDWIDTH AND TIME DELAY CONTROLS

If no fault is found in any of the previous circuits, the bandwidth and

time delay switches can be checked. As viewed from the back

(component side), 13 terminals are readily visible on each switch.

The terminal located at 11 o’clock is the center pole of the switch

and is connected directly to ground.

1. Connect the multimeter to TP

0

, set for DC volts of a scale to

read up to 5.0 volts.

2. Each terminal on the switch should measure at least 3.0 volts,

except the center pole and the terminal which corresponds to

the present switch setting, which will read zero (0). As each

switch is rotated through its settings, the “grounded” terminal

should move accordingly. Note, on the bandwidth switch, that

only 11 positions are actively used and that position 12 is con-

nected together with position 11.

3. Failure to conform indicates a defective switch, or resistor pack-

ages RP

1

, RP

2

, RP

3

, RP

4

, or decoders IC

2

and IC

6

.

CHECK NO. 6 - BAND EDGE LIGHT CIRCUITS

If the symptoms of the malfunction indicate the problem may be in

the HIGH or LOW band edge lights, they may be checked as

follows:

1. Set the control for 120.0 V setting and a 2 V bandwidth.

2. Apply 120.0 V ac to the EXTERNAL SOURCE terminals, place

the power switch on EXTERNAL, and the AUTO/OFF/ MANUAL

switch on AUTO.

3. Connect the multimeter toTP

0

, set for dc volts of a scale to read

up to 28 volts. Connect the positive meter lead to TP

14

, and

expect to measure approximately 28 V.

4. Now, slowly vary the applied voltage to below 119 V, and

observe the LOW BAND indicator, expecting it to light. The volt-

age at TP

14

should correspondingly drop to less than 1 V.

5. If the indicator does not light, but TP

14

does go low, the problem

is a defective LED DS

1

, or resistor R

23

. If TP

14

does not go low,

then the problem may be a defective IC

7

.

6. Now, reconnect the multimeter to TP

15

and expect to measure

approximately 28 V.

7. Vary the applied voltage to above 121 V, and observe the HIGH

BAND indicator, expecting it to light. The voltage at TP

15

should

correspondingly drop to less than 1 V.

8. If the indicator does not light, but TP1s does go low, the problem

is a defective LED DS

2

, or resistor R

22

. If TP

15

does not go low,

then the problem may be a defective IC

7

.

Loading...

Loading...