English

Ice cream freezer

14

6.3 Production

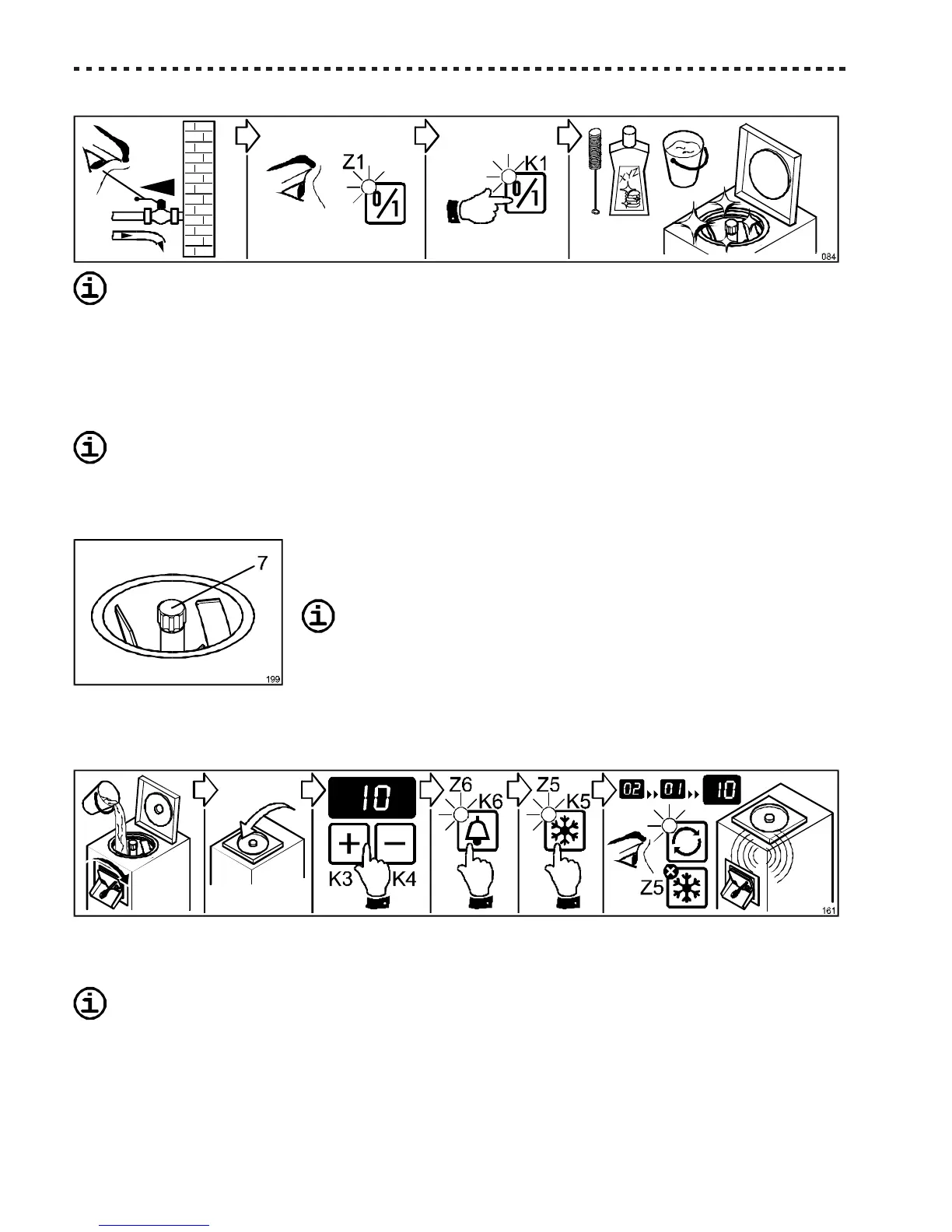

In devices with water condensation, check that the condensation water’s faucet is open;

- check that the ON/OFF Pushbutton’s indicator [Z1] is lightened. If not, check that machine is plugged in and Main

Breaker is turned on (on “I”);

- Check the lid is closed and the chute with protection flap is in position, otherwise the device will not operate.

NO “oo” (two small squares) should show on the Display;

- press the ON/OFF Pushbutton [K1].

Do not press the BEATING [K6] or REFRIGERATION/WHIPPING [K5] Pushbuttons before having intro-

duced liquids in the cylinder. The beater must not function dry, otherwise it will be damaged.

- before beginning the production, wash, rinse and proceed at the hygienisation with a detergent and disinfecting

solution (see Section 7 - WASHING).

Note: If you plan to have more than one consecutive production cycles, you can

avoid the washing between a cycle and the other, making sure you begin

with the clearer mixtures.

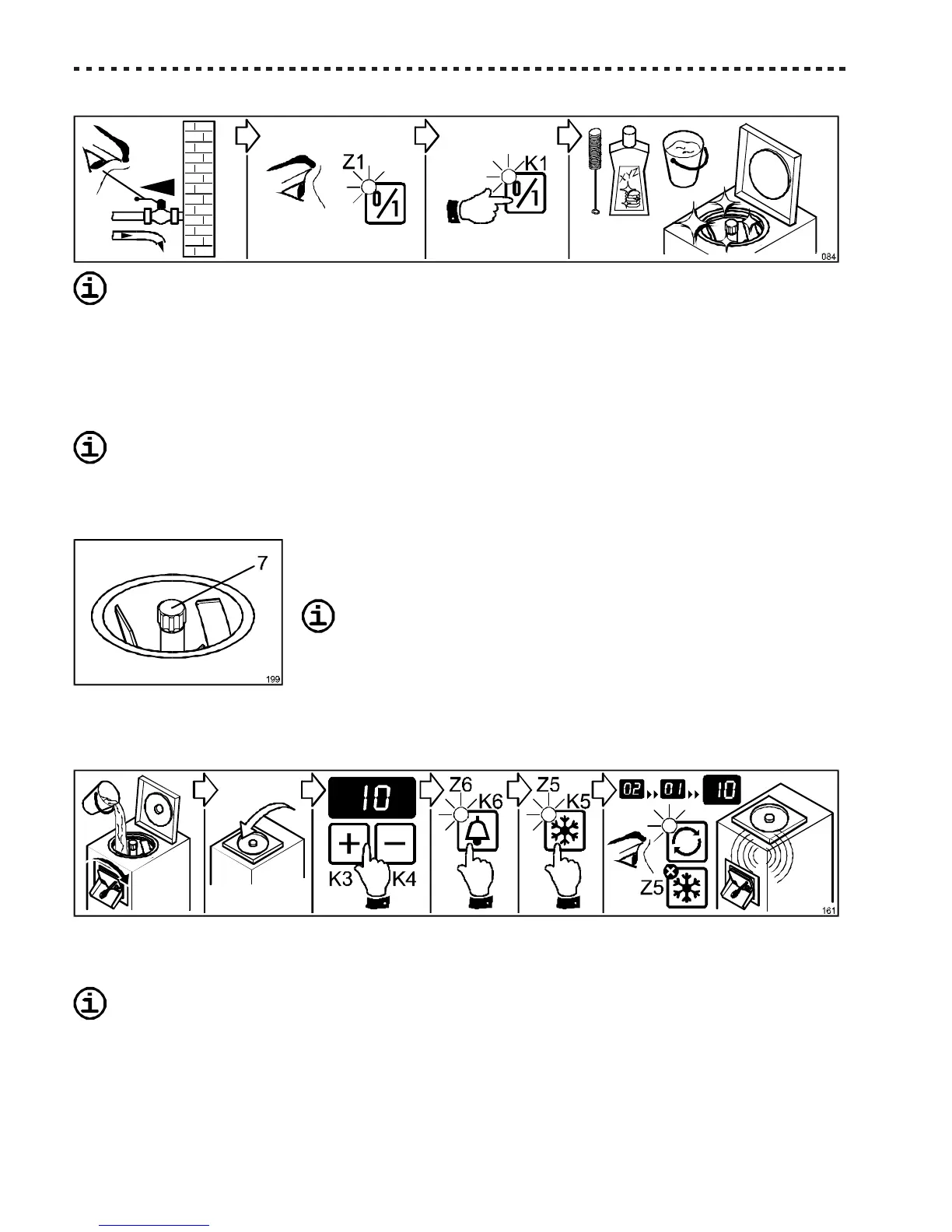

Before operating beater, ALWAYS check that beater's fixing knob [7] is

FIRMLY TIGHTENED and the gasket is intact and clear of any fat. Should

the knob accidentally come loose and fall into the cylinder while

operating, this would cause serious damage to the machine.

MODELS: GEL 25 - GAMMA 250

- check that extraction door is firmly closed and pour mixture in the cylinder. Only use suitable perfectly preserved

ingredients, in the correct amount. The maximum and minimum amounts are indicated in the Technical Handbook, in

the “Technical Data” section.

Unsuitable mixture or insufficient amount of it can cause the formation of ice, and cause damages or

irregular functioning at the cylinder and beater, while an excessive quantity of mixture can forbid the

correct whipping, in addition to causing an excessive stress at the motor and beater and overflows of

product.

- Close the lid of the whipper;

- regulate the whipping time following your experience, by pressing the SETTING Pushbuttons ([K3] and [K4]) and

reading the value (in minutes) on the display. Generally 8 to 12 minutes of whipping are necessary, in function of the

quality and quantity of the mixture;

Loading...

Loading...