Two-Stage Compressor Troubleshooting

Two-stage compressors can have problems that never

occur with single-stage machines. Interstage pressure

is an important indicator of the condition of a two-

stage compressor.

If interstage pressure is too high:

1. Second stage valves may be broken or leaking.

2. Second stage piston rings may be worn.

If interstage pressure is too low:

1. First stage valves may be broken or leaking.

2. First stage piston rings may be worn.

In most cases, problems with your Corken gas compressor

can be solved quite simply. This chart lists some of the

more frequent problems that occur with reciprocating

compressors along with a list of possible causes. If you

are having a problem which is not listed, or if you cannot

find the source of the problem, consult the factory.

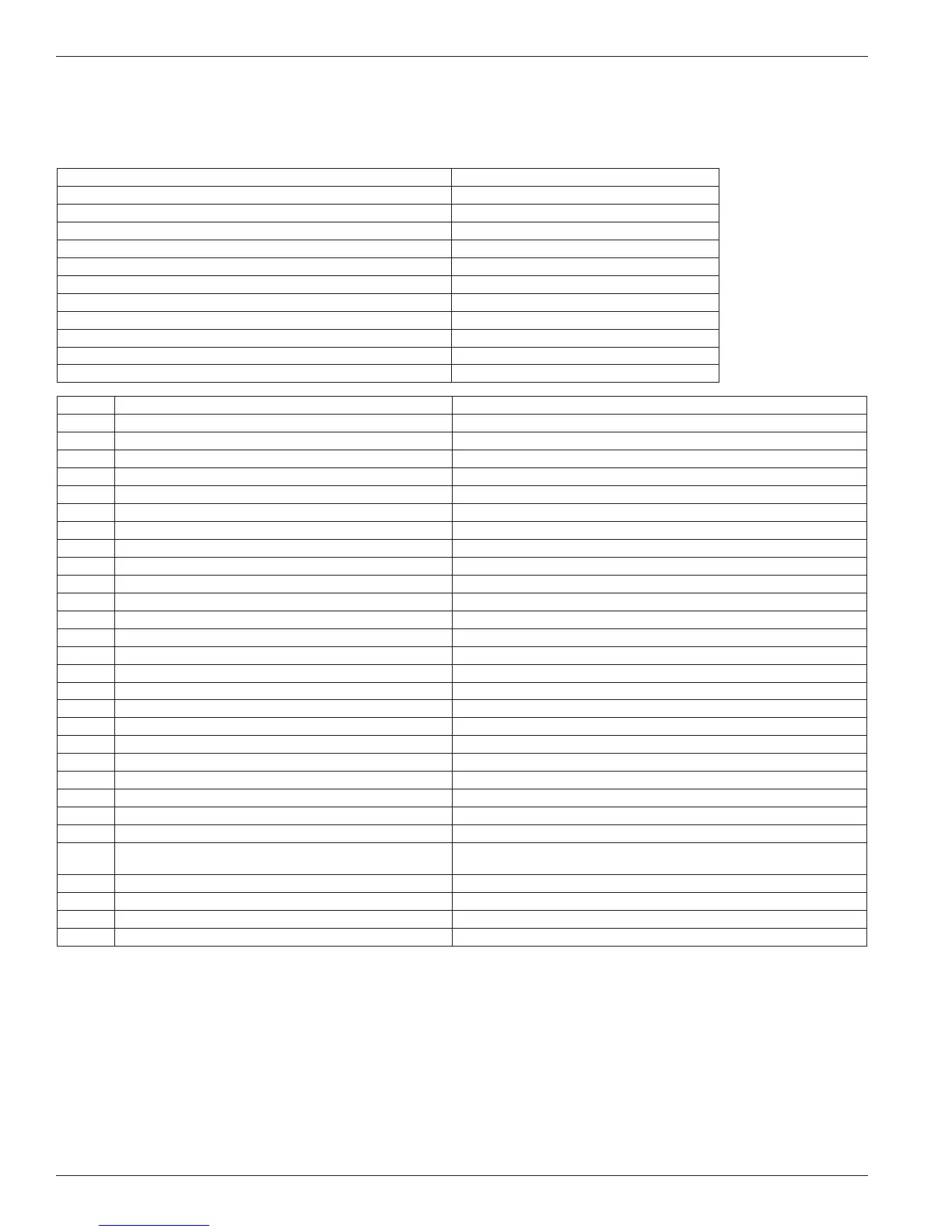

Appendix D—Troubleshooting

Problem Possible Cause

Low capacity 1, 2, 3, 4, 8, 15, 17

Overheating 1, 2, 3, 5, 6, 11, 16

Knocks, rattles and noise 1, 7, 9, 10, 11, 15

Oil in cylinder 8, 12, 15

Abnormal piston-ring wear 1, 3, 5, 6, 11, 15, 16

Product leaking through crankcase breather 8, 15

Product leakage 4, 8, 15, 17

Oil leakage around compressor base 17, 18, 19, 20

No oil pressure 19, 20

Excessive vibration 1, 7, 9, 10, 11, 13, 14, 28

Motor overheating or starter tripping out 21, 22, 23, 24, 25, 26, 27, 28

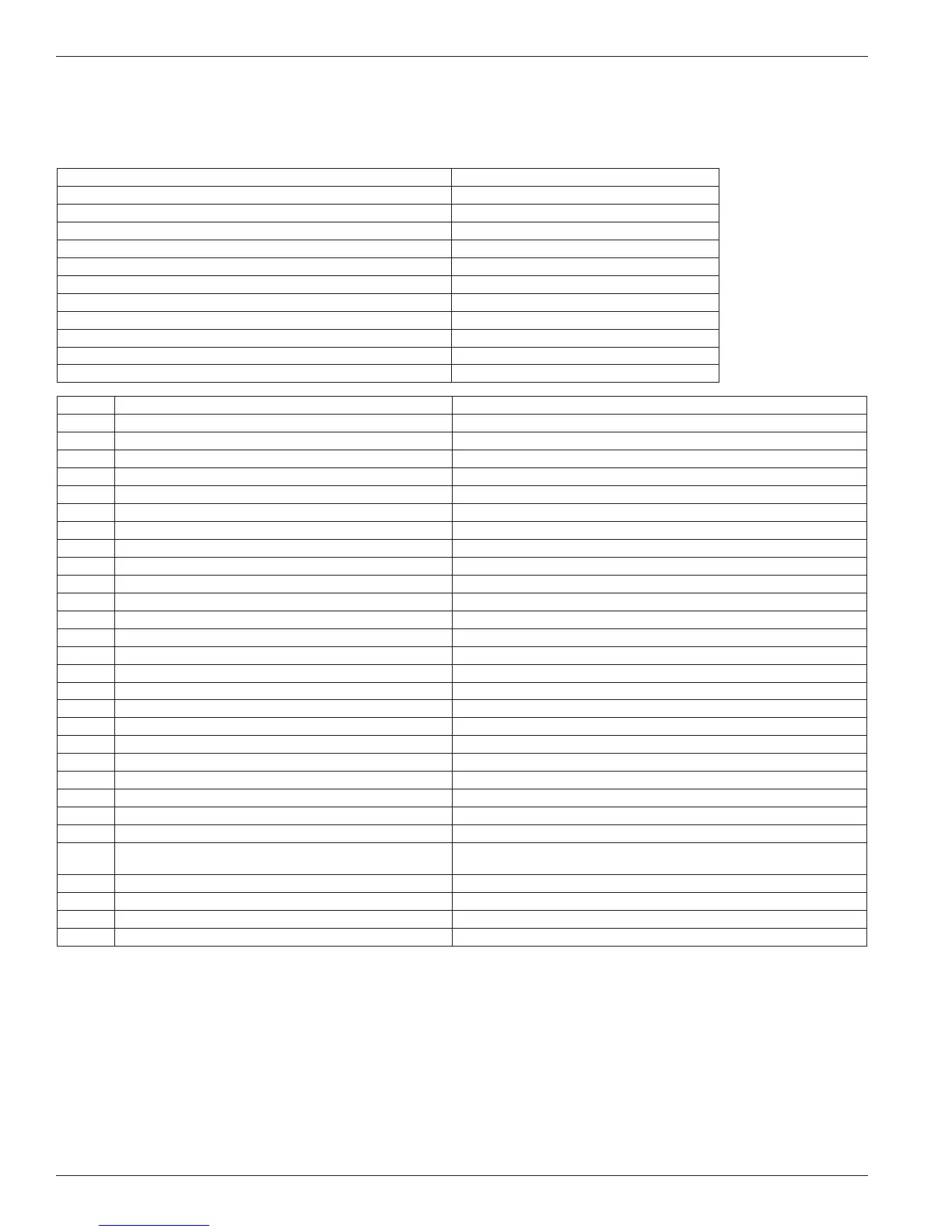

Ref. Possible Causes What To Do

1. Valves broken, stuck or leaking Inspect and clean or repair

2. Piston ring worn Inspect and replace as necessary

3. Inlet strainer clogged Clean or replace screen as necessary

4. Leaks in piping Inspect and repair

5. Inlet or ambient temperature too high Consult factory

6. Compression ratio too high Check application and consult factory

7. Loose flywheel or belt Tighten

8. Worn piston-rod packing Replace

9. Worn wrist-pin or wrist-pin bushing Replace

10. Worn connecting-rod bearing Replace

11. Unbalanced load Inspect valve or consult factory

12. Oil in distance piece Tighten packing nut — drain weekly

13. Inadequate compressor base Strengthen, replace or grout

14. Improper foundation or mounting Tighten mounting or rebuild foundation

15. Loose valve, piston or packing Tighten or replace as necessary

16. Dirty cooling fins Clean weekly

17. 4-way control valve not lubricated Inspect and lubricate

18. Leaking gas blowing oil from crankcase Tighten packing

19. Bad oil seal Replace

20. No oil in crankcase Add oil

21. Oil-pump malfunction See oil pressure adjustment

22. Low voltage Check line voltage with motor nameplate. Consult power company

23. Motor wired wrong Check wiring diagram

24. Wire size too small for length of run Replace with correct size

25. Wrong power characteristics Voltage, phase and frequency must coincide with motor nameplate.

Consult with power company.

26. Wrong size of heaters in starter Check and replace according to manufacturer’s instructions

27. Compressor overloading Reduce speed

28. Motor shorted out See driver installation

29. Bad motor bearing Lubricate according to manufacturer’s instructions

Another cause for high interstage pressure is a low

compression ratio. Two-stage machines should not be

used in applications where the compression ratio is

below 5. To use two-stage compressors in this kind of

situation results in rapid ring wear, machine imbalance

and excessive horsepower. If you think you have a

problem in this area, consult factory.

D. Troubleshooting

32

Loading...

Loading...