C Energize proizvodna serija

35

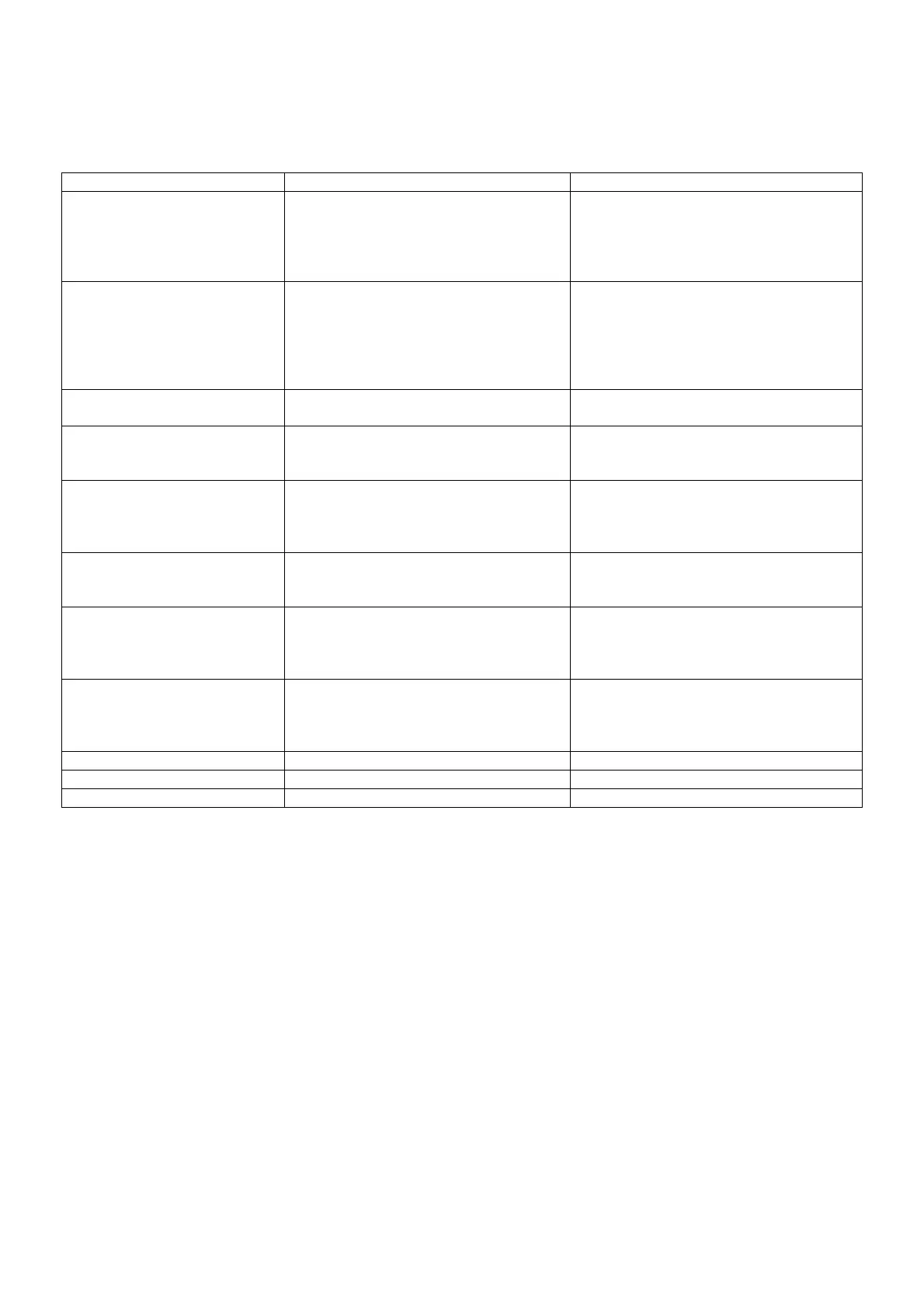

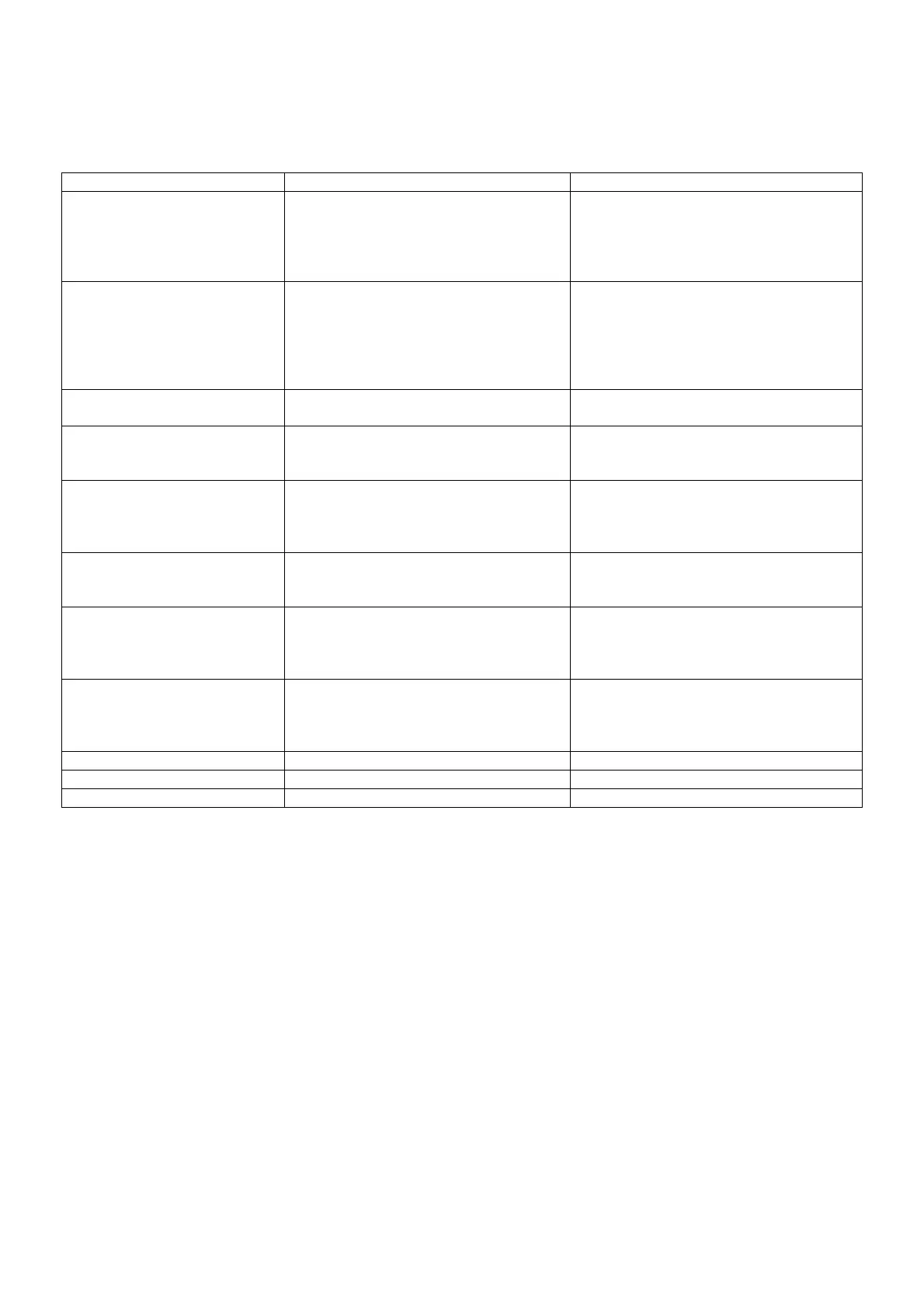

12. Diagnostic messages

Message Cause Remedy

CO

2

pressure NOK

CO

2

inlet pressure below operating pressure

of 6 bar

Check CO

2

supply

Change CO

2

cylinder

Adjust pressure regulator

Check CO

2

pressure switch

Check electric connections

Carbonator pump NOK

Carbonator pump pressure below operation

pressure of 10 bar

Check carbonator bowl

Check CO

2

supply

Change carbonator pump

Change carbonator pump motor

Check Carbonator pressure switch

Check electric connections

Water inlet pressure NOK

H2O inlet pressure below operating

pressure of 0,2 bar

Check H2O supply

Check electric connections

Agitator NOK

Agitator RPM speed below adjusted

settings of 1570 min

-1

respectively 3880

min

–1

Check agitator motor

Check electric connections

Water bath temperature NOK

Water bath temperature above operating

temperature of or dispense rate at capacity

Check temperature probe

Check electric connections

Ice bank used up, allow time to build new

ice bank and / or reduce dispense rate

Ambient temperature NOK

Ambient temperature above maximum

specification of 40°C

Check temperature probe

Check electric connection

Improve room ventilation

Soda temperature NOK

Soda return temperature above operating

temperature of max. 2°C, or dispense rate is

at capacity

Check temperature probe

Check electric connection

Ice bank used up, allow time to build new

ice bank and / or reduce dispense rate

Hot gas temperature NOK

Condenser temperature above operating

temperature of max. 120°C

Check temperature probe

Check electric connections

Provide sufficient ventilation

Clean condenser fins

Compressor run time For information only

Carbonator pump run time For information only

Voltage check NOK Power supply out of specification Check power supply conditions

Loading...

Loading...